Isuzu N-Series. Manual - part 496

Engine Mechanical (4HK1-TC) 6A-89

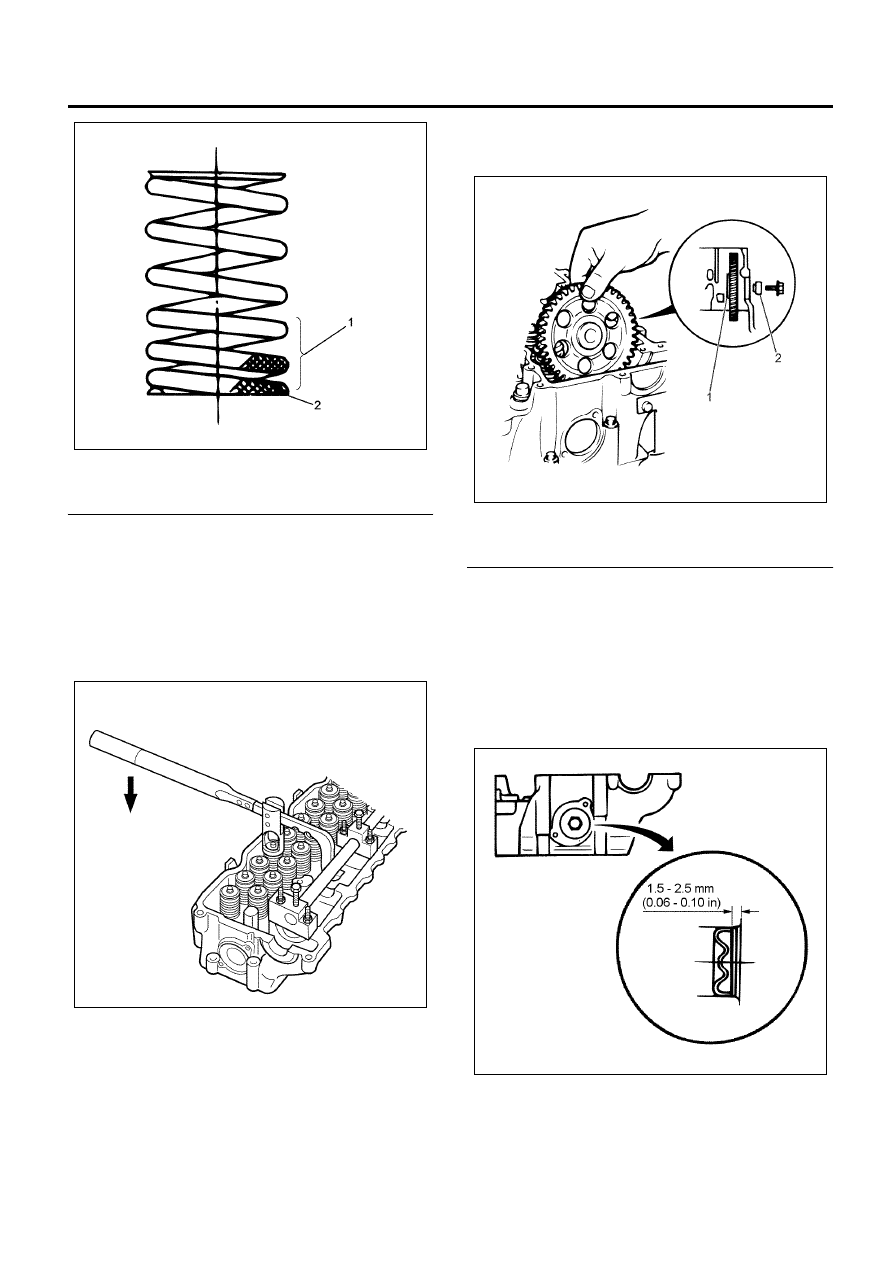

Legend

1. Spring Pitch

2. Paint Mark

8. Install the spring upper sheet.

9. Install the split collar.

• Use the replacer to compress the valve spring

and install the split collar.

Special tool

Valve spring replacer: 5-8840-2621-0 (J-43263)

Pivot: 5-8840-2808-0 (EN-46721)

10. Install the idle gear C.

• Apply engine oil on the idle gear C shaft and

the inner diameter of the idle gear, install the

idle gear C so that the side with gear groove is

on the side of the rear surface of the engine.

• Tighten the idle gear C with the designated

torque.

• Do not use impact wrench and like.

Tighten:

Bolt to 95 N

⋅m (9.7 kg⋅m/70 lb⋅ft)

Legend

1. Idle Gear C

2. Shaft

11. Install the idle gear C cover.

• Apply liquid gasket (Loctite 262) on the outer

diameter of the idle gear C cover, use the

sealing cup setting tool to hammer it in so that

the measurements follow the drawing.

Special tool

Sealing cup installer: 5-8840-2222-0

(EN-47690)

12. Install the thermostat.

N6A6119E

N6A6113E

N6A6134E

N6A6165E