Isuzu N-Series. Manual - part 460

6E-176 EMISSION AND ELECTRICAL DIAGNOSIS

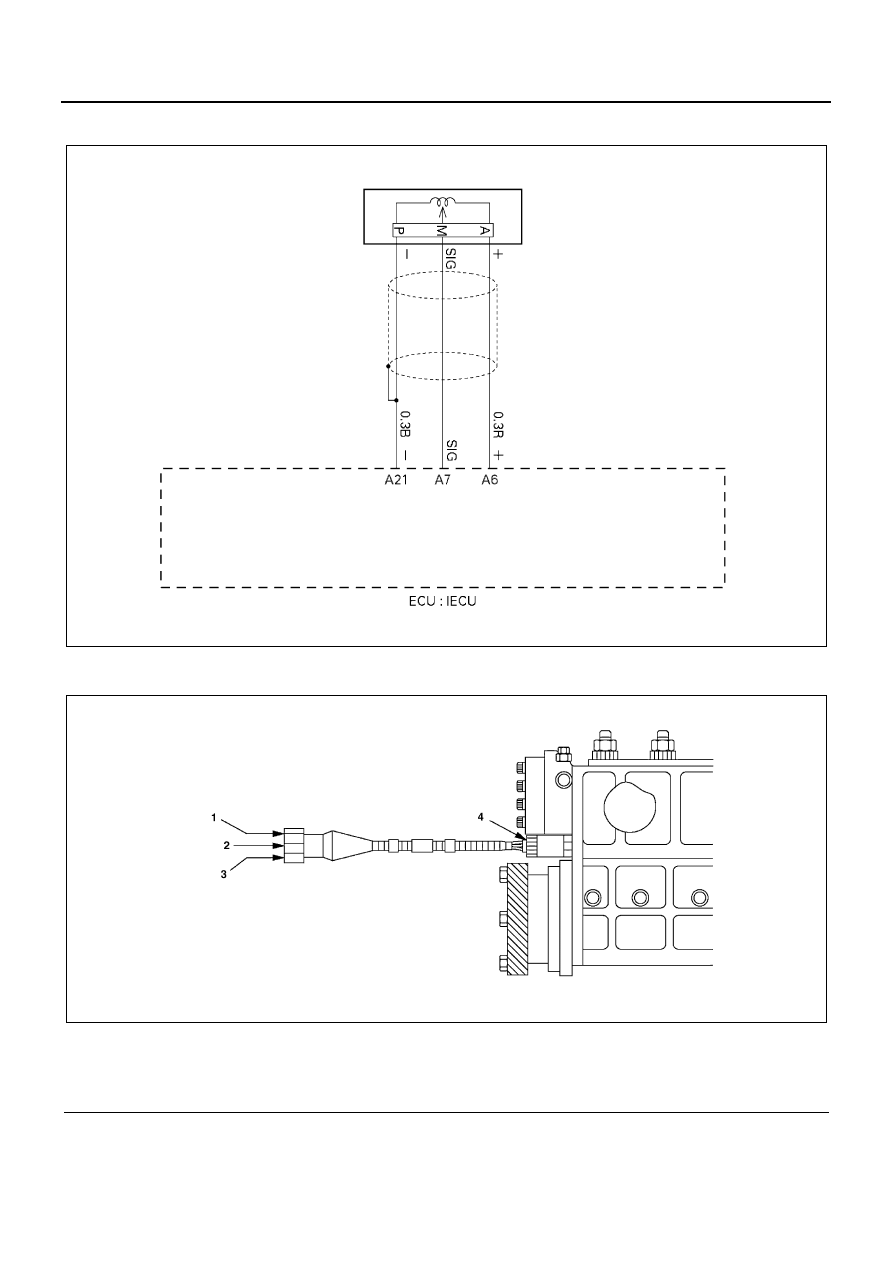

DTC-22 Rack Sensor Circuit High Voltage

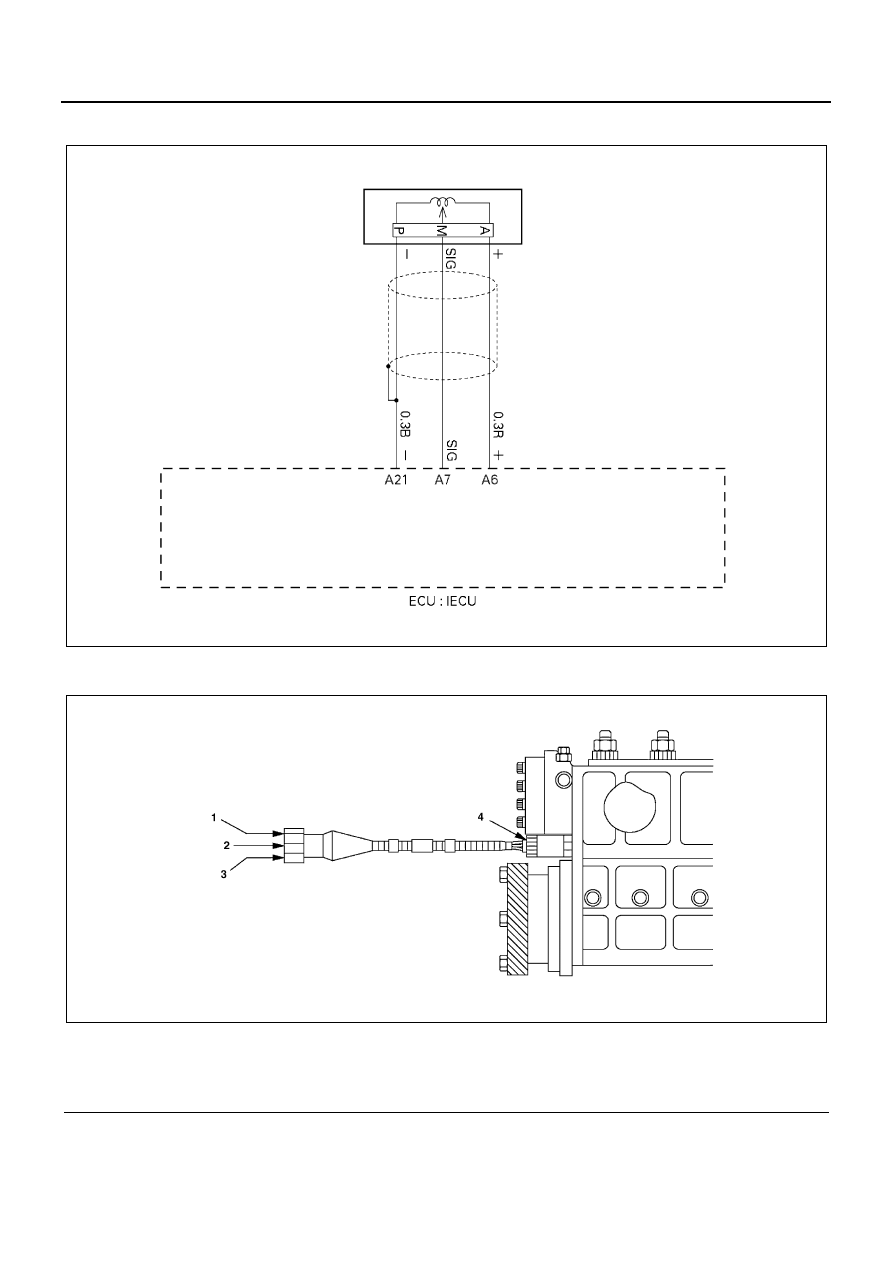

Location of Rack Sensor Connector

Legend

1. OSC (red)

3. GND (black)

2. MDL (white)

4. Rack sensor

N6A1319E

N6A1320E

|

|

|

6E-176 EMISSION AND ELECTRICAL DIAGNOSIS DTC-22 Rack Sensor Circuit High Voltage Location of Rack Sensor Connector Legend 1. OSC (red) 3. GND (black) 2. MDL (white) 4. Rack sensor N6A1319E N6A1320E |