Isuzu N-Series. Manual - part 425

6E-36 EMISSION AND ELECTRICAL DIAGNOSIS

Governor (Model RLD-M)

The RLD-J type governor can be used with the MI,

MITICS injection pumps, and was designed to have bet-

ter control and endurance than the previous RLD type

governor.

Although the basic construction is identical to that of the

RLD type governor, the RLD-M type is larger to match

the applicable pumps’ larger size.

Features

Variable speed control governor with decreased le-

ver reaction force

As with the previous RLD type governor, RLD-M gover-

nor control is accomplished using the speed control le-

ver to change the fulcrum of the internal link mechanism.

Consequently, as the reaction force of the governor

spring does not act directly on the speed control lever,

only a very small lever reaction force is exerted on the

accelerator pedal.

Set torque characteristics through internal torque

cam

At full load, the tip of the sensor lever traces the face of

the torque cam to determine the full load rack position

and control the full load injection quantity.

Consequently, the torque characteristics demanded by

the engine can be freely set by changing the shape of

the torque cam face.

Improved control through internal guide plate

When the speed control lever is operated, the 2nd sup-

porting lever’s pin moves along the guide plate. The

floating lever connected to the pin thus moves to change

the ball joint fulcrum positions.

In the intermediate to high speed ranges, the guide plate

causes the floating lever to move to increase the lever

ratio continuously from 1.1 (idling) — 6 (full speed). This

increase in the lever ratio in the intermediate to high

speed range improves speed droop.

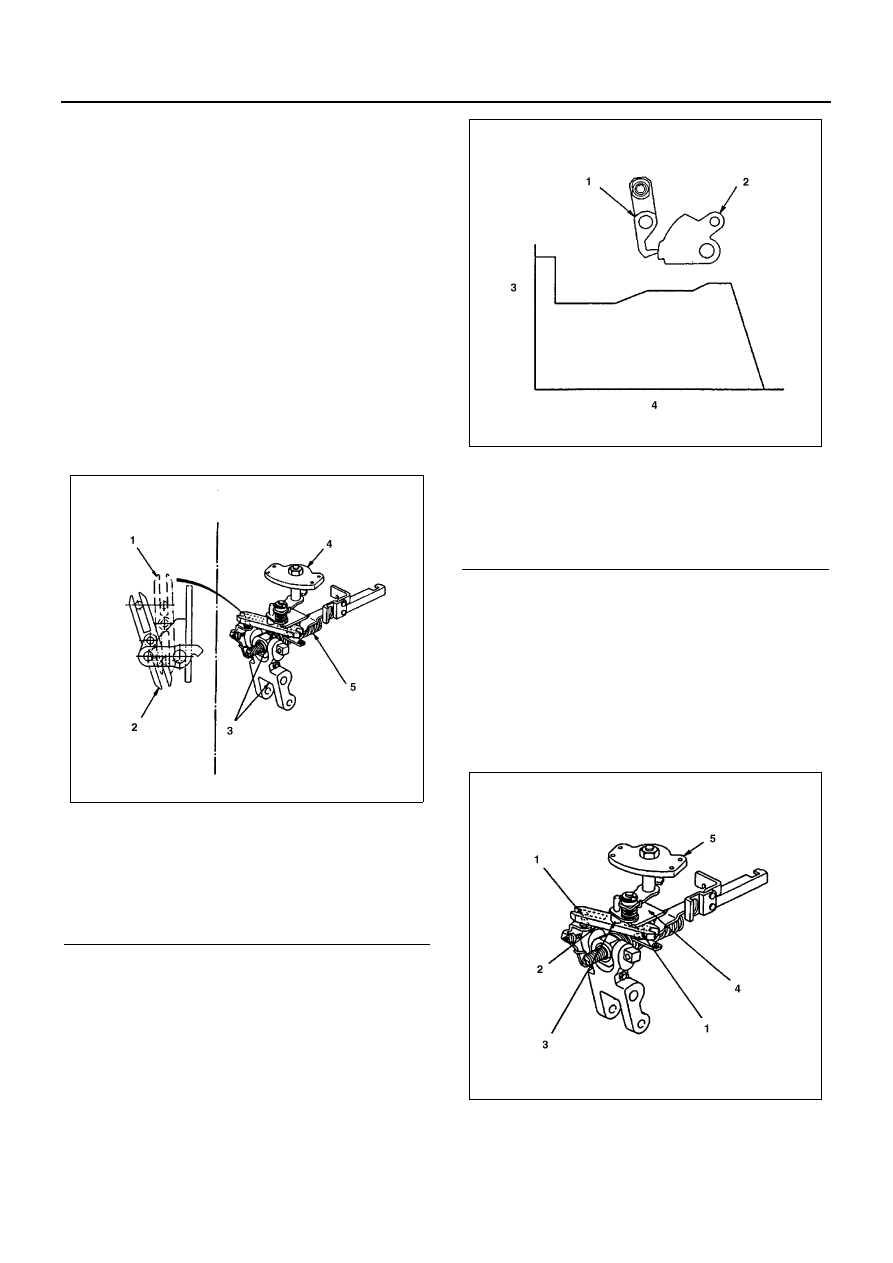

Legend

1. At maximum speed control

2. At idle speed control

3. Link mechanism

4. Speed control lever

5. Governor spring

N6A1147E

Legend

1. Sensor lever

2. Torque cam

3. Control rack position (mm)

4. Pump speed (r/min)

N6A1148E

N6A1149E