Isuzu N-Series. Manual - part 338

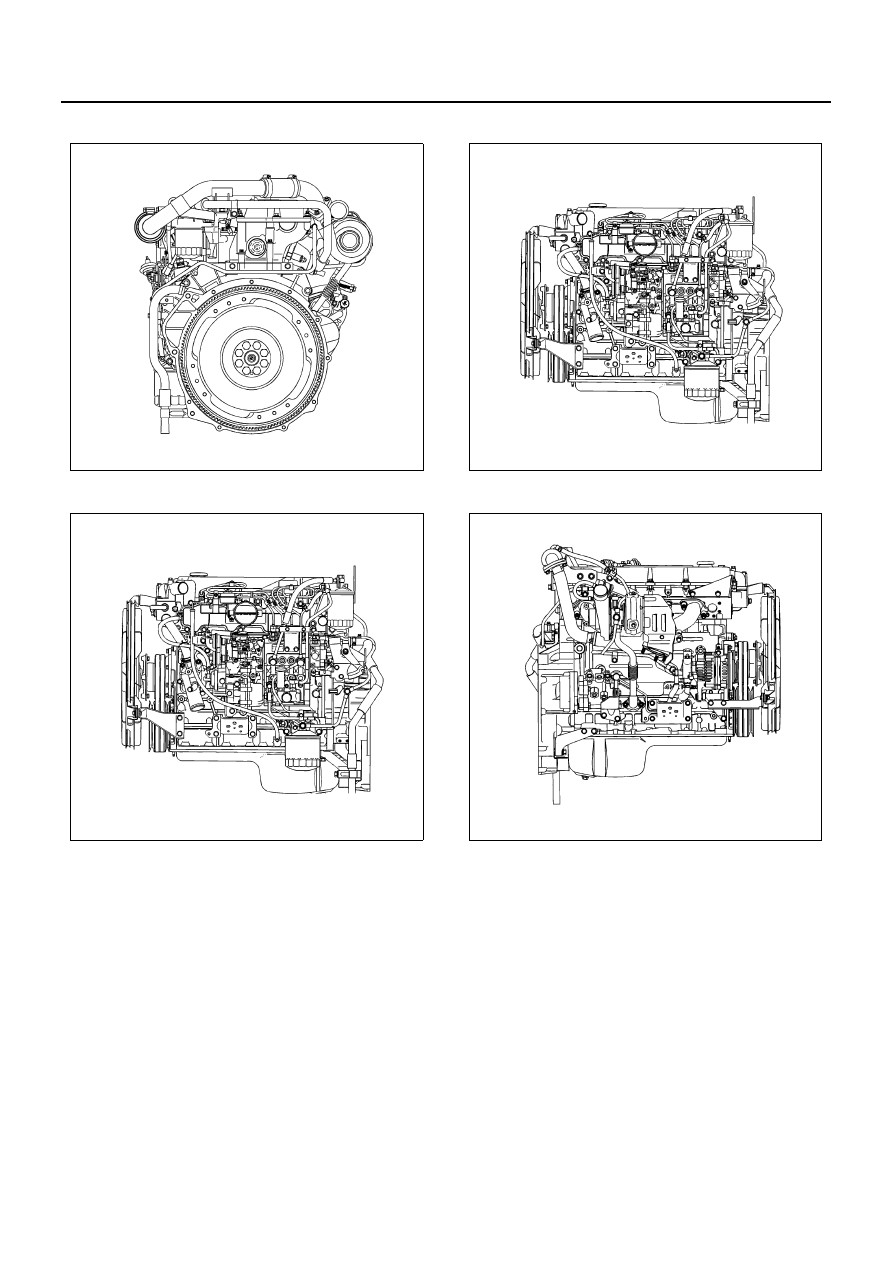

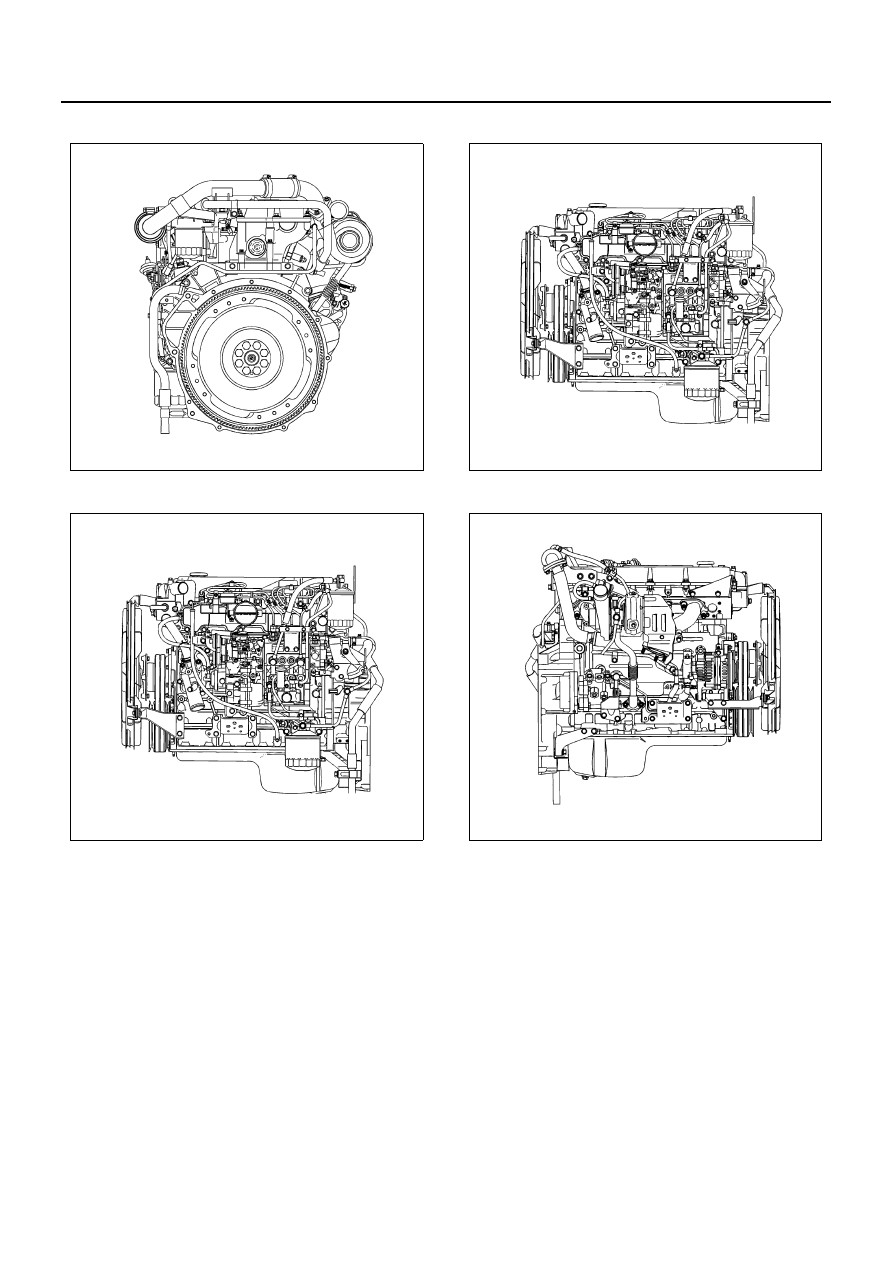

6A3-4 ENGINE (4HF1 / 4HF1-2 / 4HE1-TC / 4HG1 / 4HG1-T)

For 4HG1-T

For 4HE1-TC (4HE1-XS) 98EPA

For 4HE1-TC (4HE1-XS) 98EPA

For 4HE1-TC (4HE1-XS) SPEC. EURO3

N6A0362E

N6A0363E

N6A0364E

N6A0365E

|

|

|

6A3-4 ENGINE (4HF1 / 4HF1-2 / 4HE1-TC / 4HG1 / 4HG1-T) For 4HG1-T For 4HE1-TC (4HE1-XS) 98EPA For 4HE1-TC (4HE1-XS) 98EPA For 4HE1-TC (4HE1-XS) SPEC. EURO3 N6A0362E N6A0363E N6A0364E N6A0365E |