Isuzu N-Series. Manual - part 248

ANTI-LOCK BRAKE SYSTEM (ABS) 5A4-57

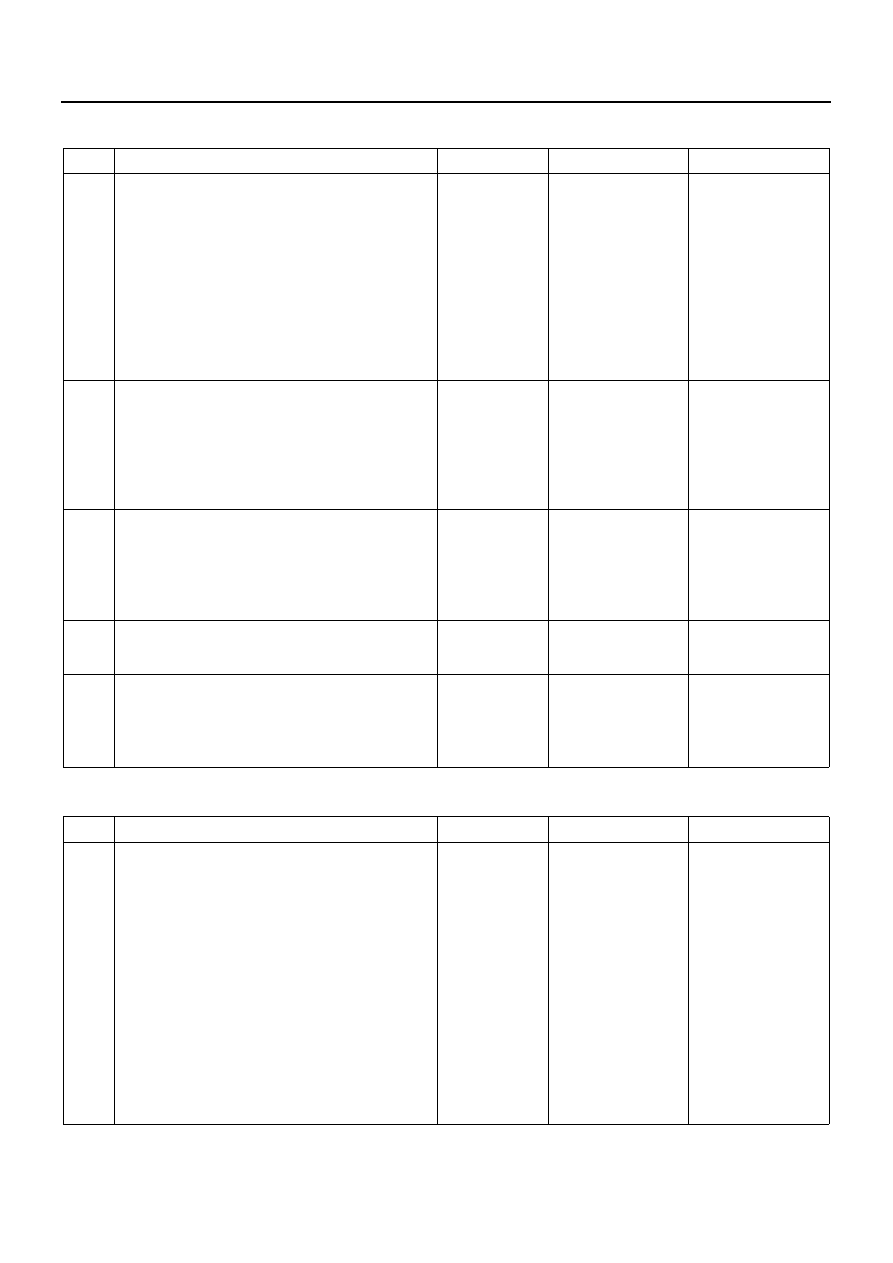

Chart C-1-2 FR Speed Sensor Output Inspection Procedure

Chart C-1-3 RL Speed Sensor Output Inspection Procedure

Step

Action

Value(s)

YES

NO

1

1. Turn the key off.

2. Disconnect EHCU connector.

3. Jack up the vehicle, with all wheels off the

ground.

4. Measure the AC voltage between J-177

EHCU connector terminals 10 and 11

while turning FR wheel at a speed of 0.5

RPS.

Does the DVM display a voltage within the

specified value?

200 mV or

more

2

1. Disconnect FR sensor connector.

2. Using DVM, measure the resistance be-

tween J-74 sensor connector terminals 1

and 2.

Does the DVM display a resistance within the

specified value?

1.0 — 2.0 k

ohms

3

1. Locate open circuit, poor connection or

short circuit on the harness between

EHCU and sensor connectors.

2. Repair the harness.

Is action complete?

—

—

4

Replace FR sensor.

Is action complete?

—

—

5

1. Reconnect all components, ensure all

components are properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

—

Go to “Basic diag-

nostic flow chart”.

—

Step

Action

Value(s)

YES

NO

1

1. Turn the key off.

2. Disconnect EHCU connector.

3. Jack up the vehicle, with all wheels off the

ground.

4. Connect a 120 ohms resistor between J-

177 EHCU connector terminal 22 and

ground. Apply voltage of 12 V to EHCU

connector terminal 22.

5. Using DVM, measure the DC voltage be-

tween J-177 connector terminal 22 and

ground while turning RL wheel at a speed

of 0.5 RPS.

Does the DVM display a voltage within the

specified value?

0.2 — 4.5 V