Isuzu N-Series. Manual - part 61

1B-14 AIR CONDITIONING

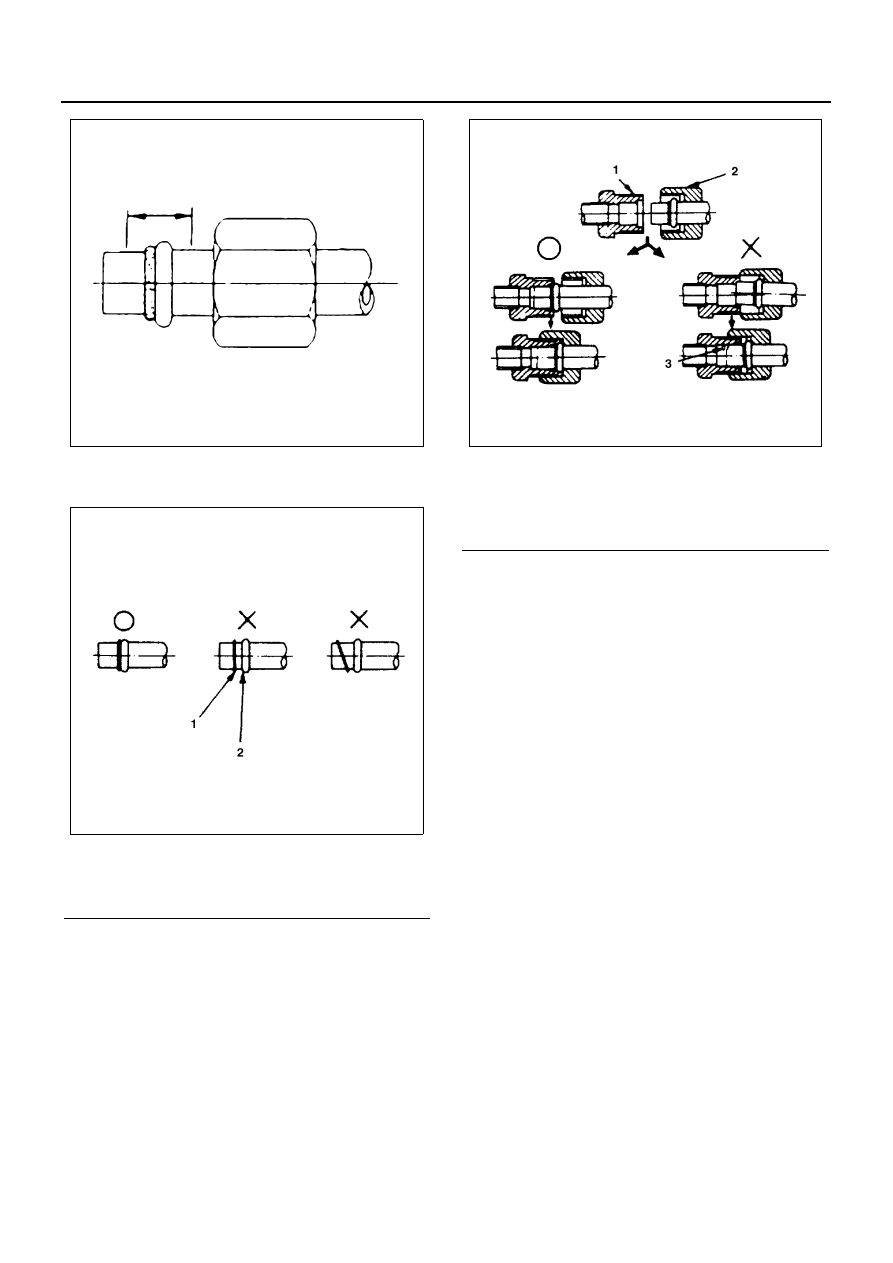

O-rings must be closely aligned with raised portion of re-

frigerant line.

Insert nut into union. First tighten nut by hand as much

as possible. Then, tighten nut to specified torque.

(Refer to “SERVICE INFORMATION” for Fixing Torque

in section 00)

Leak at Refrigerant Line Connections

1. Check the torque on the refrigerant line fitting and,

if too loose, tighten to the specified torque.

• Use two wrenches to prevent twisting and damage

to the Line.

• Do not over tighten.

2. Perform a leak test on the refrigerant line fitting.

3. If the leak is still present, discharge and recover the

refrigerant from the system.

4. Replace the O-rings.

• O-rings cannot be reused. Always replace with

new ones.

• Be sure to apply specified compressor oil to the

new O-rings.

5. Retighten the refrigerant line fitting to the specified

torque.

• Use two wrenches to prevent twisting and damage

to the line.

6. Evacuate, charge and retest the system.

Leak in The Hose

If the compressor inlet or outlet hose is leaking, the en-

tire hose must be replaced. Refrigerant hose must not

be cut or spliced for repair.

1. Locate the leak.

2. Discharge and recover the refrigerant.

3. Remove the hose assembly.

• Cap the open connections at once.

4. Connect the new hose assembly.

• Use two wrenches to prevent twisting or damage to

the hose fitting.

Legend

1. O-ring

2. Raised portion

N1A0064E

N1A0065E

Legend

1. Union

2. Nut

3. Damage

N1A0066E