Isuzu engine 4j series. Manual - part 55

6A1 – 88 4JB1/4JB1T/4JB1TC/4JG2 - ENGINE

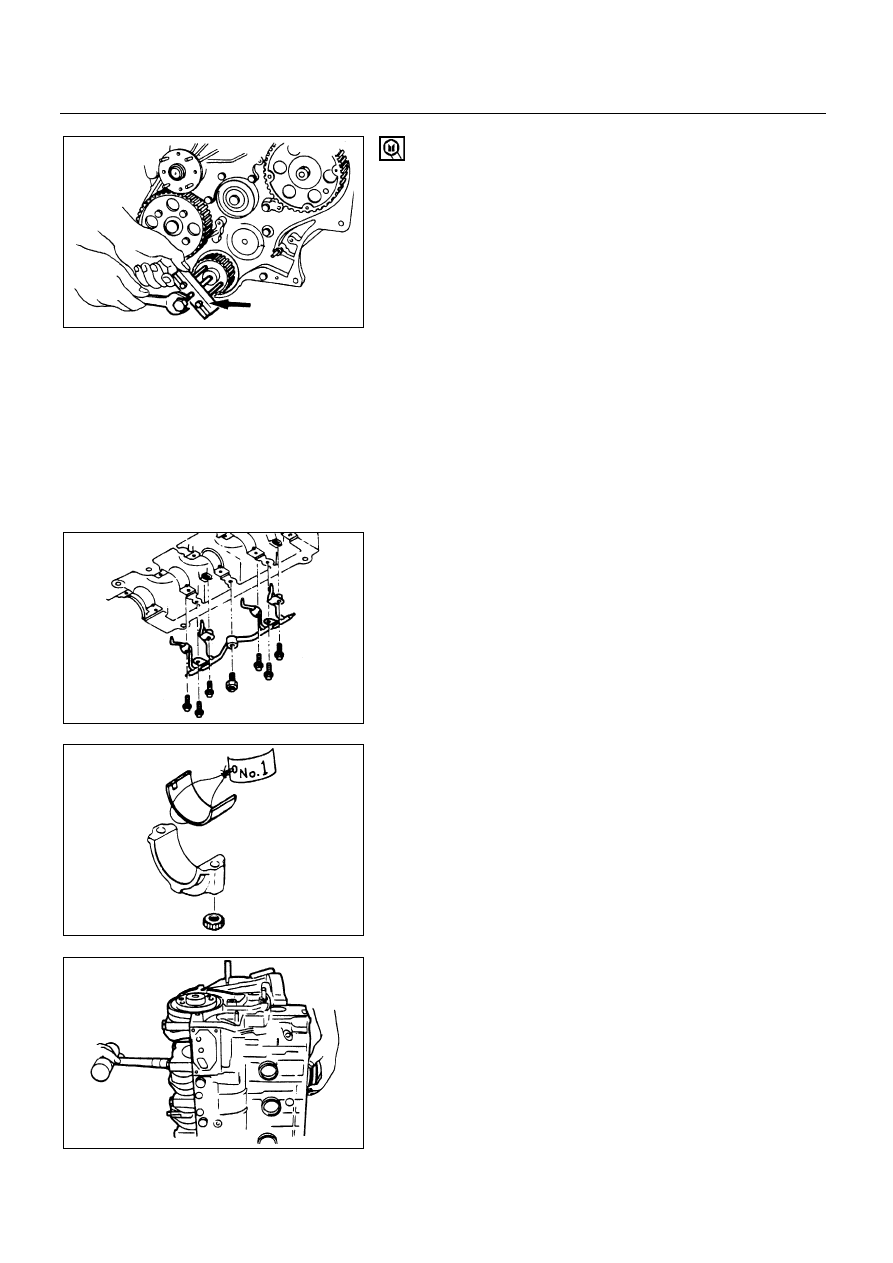

9) Crankshaft timing pulley

•

Block the crankshaft with a piece of hard wood.

•

Use the crankshaft timing pulley puller to remove the

timing pulley.

Crankshaft Timing Pulley Puller: 5-8840-2035-0

10) Injection pump timing pulley

11) Injection pump

Above works refer to “CYLINDER BLOCK

ASSEMBLY” Section in this manual.

12) Camshaft timing pulley

5. Oil Pan Assembly

6. Oil Pump Assembly

Above works refer to “CAMSHAFT AND TAPPET” Section

in this manual.

7. Piston Cooling Oil Pipe

•

Remove the oil pipe from cylinder block.

8. Piston and Connecting Rod Assembly

•

If the connecting rod lower bearings are to be

reinstalled, mark their fitting positions by tagging each

bearing with the cylinder number from which it was

removed.

•

Remove carbon deposits from the upper portion of the

cylinder wall with a scraper before removing the piston

and connecting rod.

Move the piston to the top of the cylinder and tap it

with a hammer grip or similar object from the

connecting rod lower side to drive it out.

6A1-88-1.tif

6A1-88-2.tif

6A1-88-3.tif

6A1-88-4.tif