Isuzu Trooper (2000 year). Manual - part 15

HEATING, VENTILATION AND AIR CONDITIONING (HVAC) 1A–29

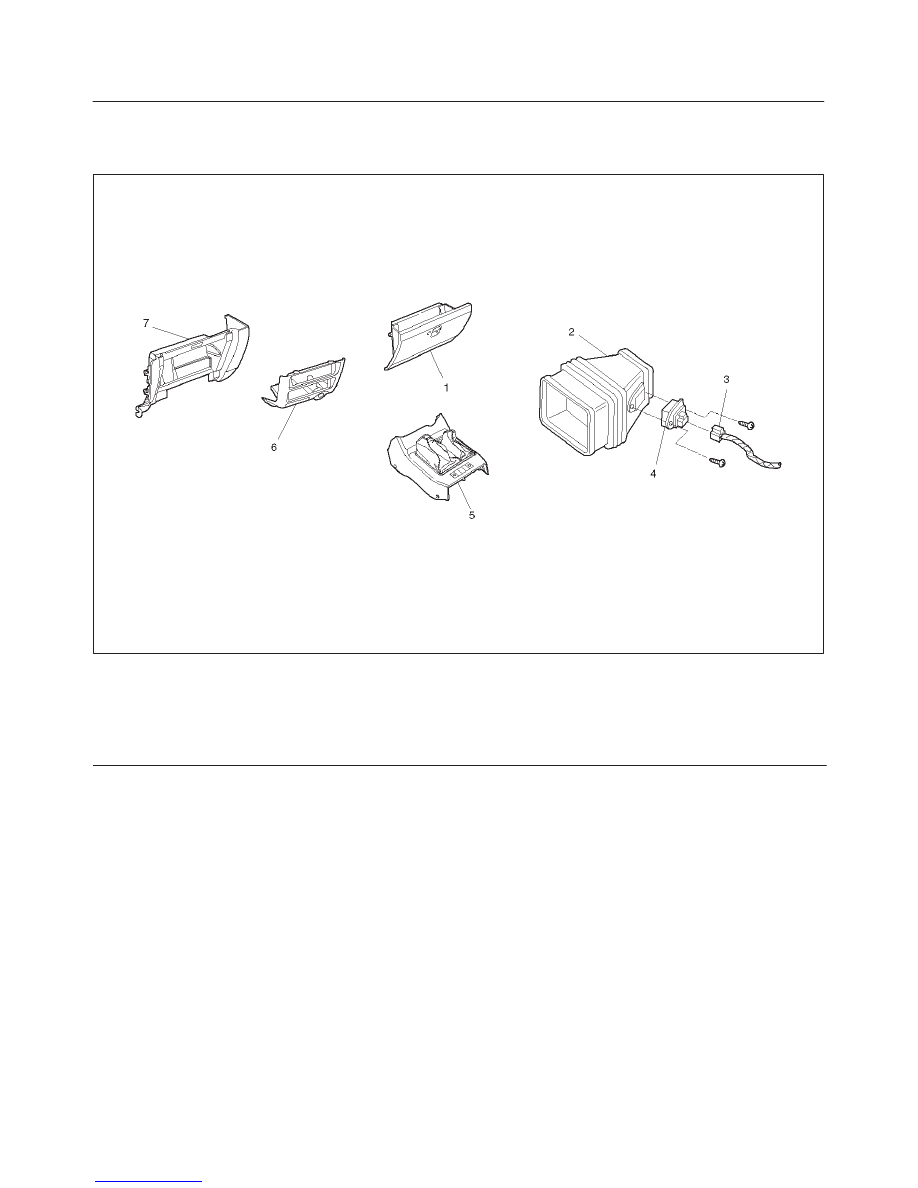

Resistor

Resistor and Associated Parts

874RW005

Legend

(1) Glove Box

(2) Duct (Heater only)

(3) Resistor Connector

(4) Resistor

(5) Front Console

(6) Lower Cluster

(7) Instrument Panel Passenger Lower Cover

Assembly

Removal

1. Disconnect the battery ground cable.

2. Remove front console.

3. Remove lower cluster.

4. Remove glove box.

5. Remove instrument panel passenger lower cover

assembly.

D

Refer to Instrument Panel Assembly in Body and

Accessories section.

6. Remove resistor connector.

7. Remove duct (heater only).

8. Remove resistor.

Installation

To install, follow the removal steps in the reverse order.