Isuzu Rodeo UE. Manual - part 411

6E2–399

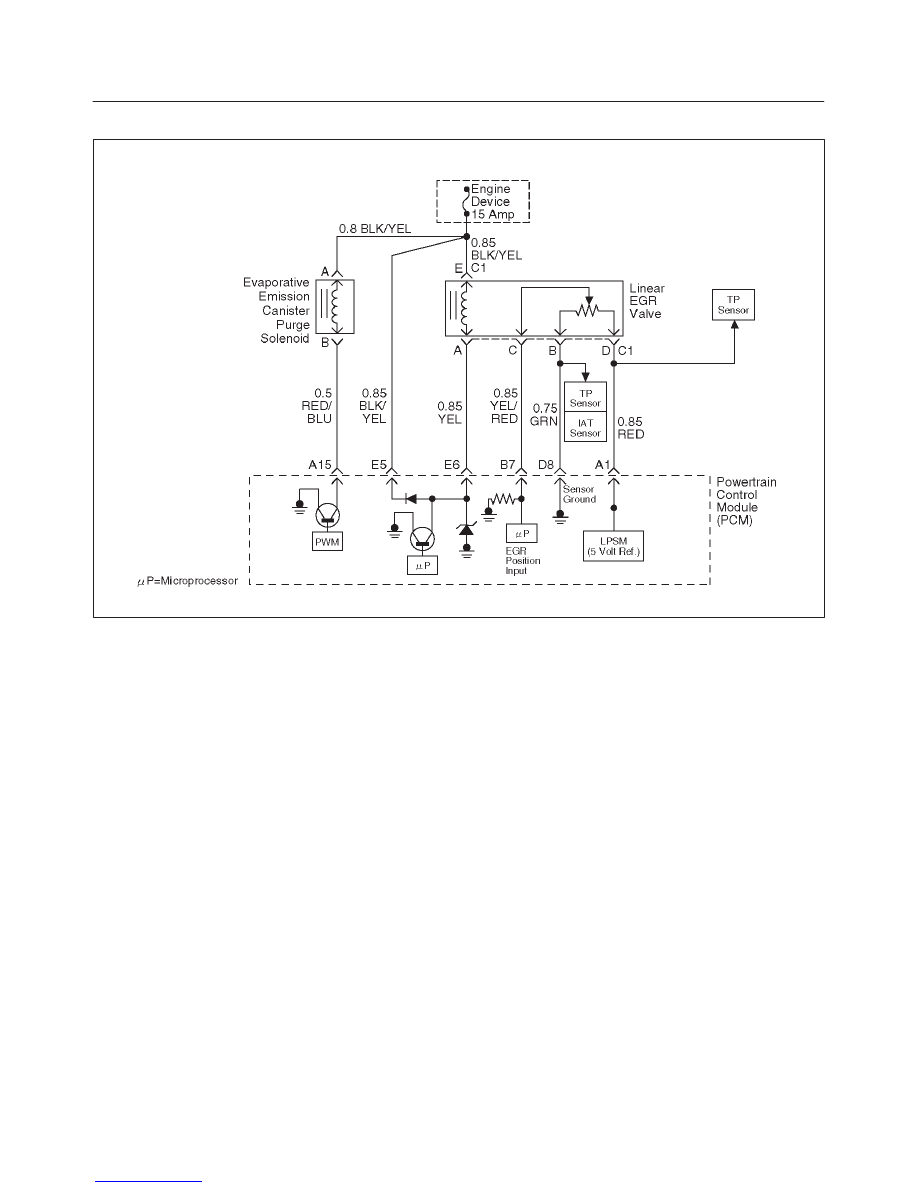

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1404 EGR Stuck Closed

D06RW055

Circuit Description

The powertrain control module (PCM) monitors the EGR

valve pintle position input to ensure that the valve

responds properly to commands from the PCM, and to

detect a fault if current pintle zero position is different from

the learned zero position. If the PCM detects a pintle

position signal indicates more than 30 % different

between current zero position and the learned zero

position for more than 5 seconds, and this condition exists

3 times during trip, then the PCM will set DTC P1404.

Conditions for Setting the DTC

f

Ignition voltage is between 11 and 16 volts.

f

Intake Air temp is more than 3

°

C.

f

Desired EGR position is 0.

f

Difference of EGR pintle position between current and

the learned zero is more than 30 % for more than 5

seconds, and exists three time to the above condition

during a trip the PCM will set DTC 1404. Then it trigger

the PCM lights on.

Action Taken When the DTC Sets

f

The PCM will illuminate the malfunction indicator lamp

(MIL) after consecutive 2nd trip in which the fault is

detected.

f

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in Failure

Records data.

Conditions for Clearing the MIL/DTC

f

The PCM will turn the MIL “OFF” on the third

consecutive trip cycle during which the diagnostic has

been run and the fault condition is no longer present.

f

A history DTC P1404 will clear after 40 consecutive

warm-up cycles have occurred without a fault.

f

DTC P1404 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

f

Excessive carbon deposit on EGR valve shaft and/or

foreign material may cause the EGR valve not to fully

seated. The carbon deposit may occur by unusual port

operation. Remove foreign material and/or excessive

carbon deposit on EGR valve shaft may allow the EGR

valve to be fully seated.

f

Poor connection or damaged harness – Inspect the

wiring harness for damage.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.