Isuzu Rodeo UE. Manual - part 393

6E2–327

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

DTC P0440 – EVAP System

(Cont'd)

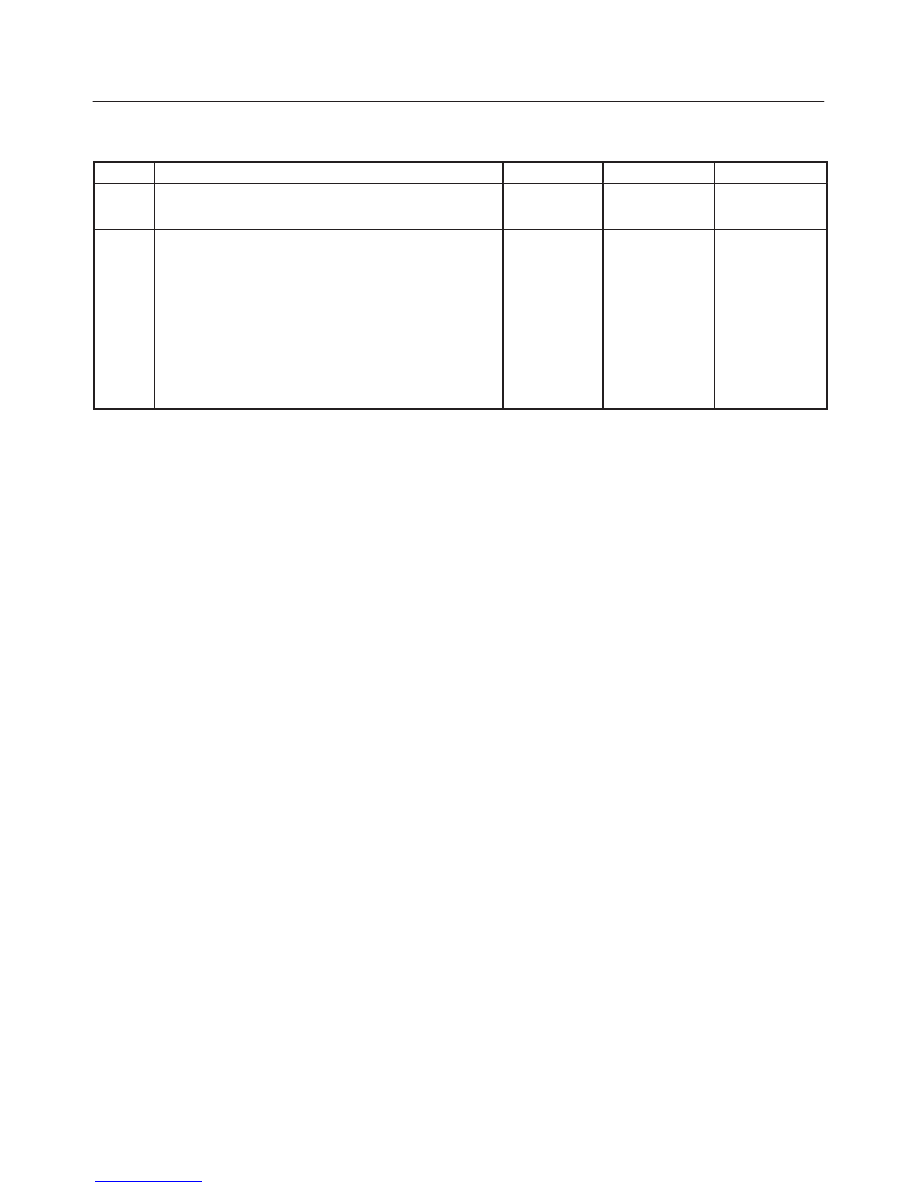

Step

No

Yes

Value(s)

Action

15

Replace the EVAP canister vent solenoid.

Is the action complete?

—

Go to

Step 16

—

16

1. Ignition “ON,” engine not running.

2. Using the Tech 2, command the EVAP canister vent

solenoid “ON” (closed).

3. Using the EVAP pressure/purge cart J 41413,

pressurize and monitor the EVAP system to 15 in.

H2O.

4. Switch the rotary switch on the cart to “HOLD” and

observe the EVAP pressure gauge.

Does the pressure decrease to less than the specified

value within 2 minutes?

2.14V

Go to

Step 3

Verify repair