Isuzu Rodeo UE. Manual - part 390

6E2–315

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

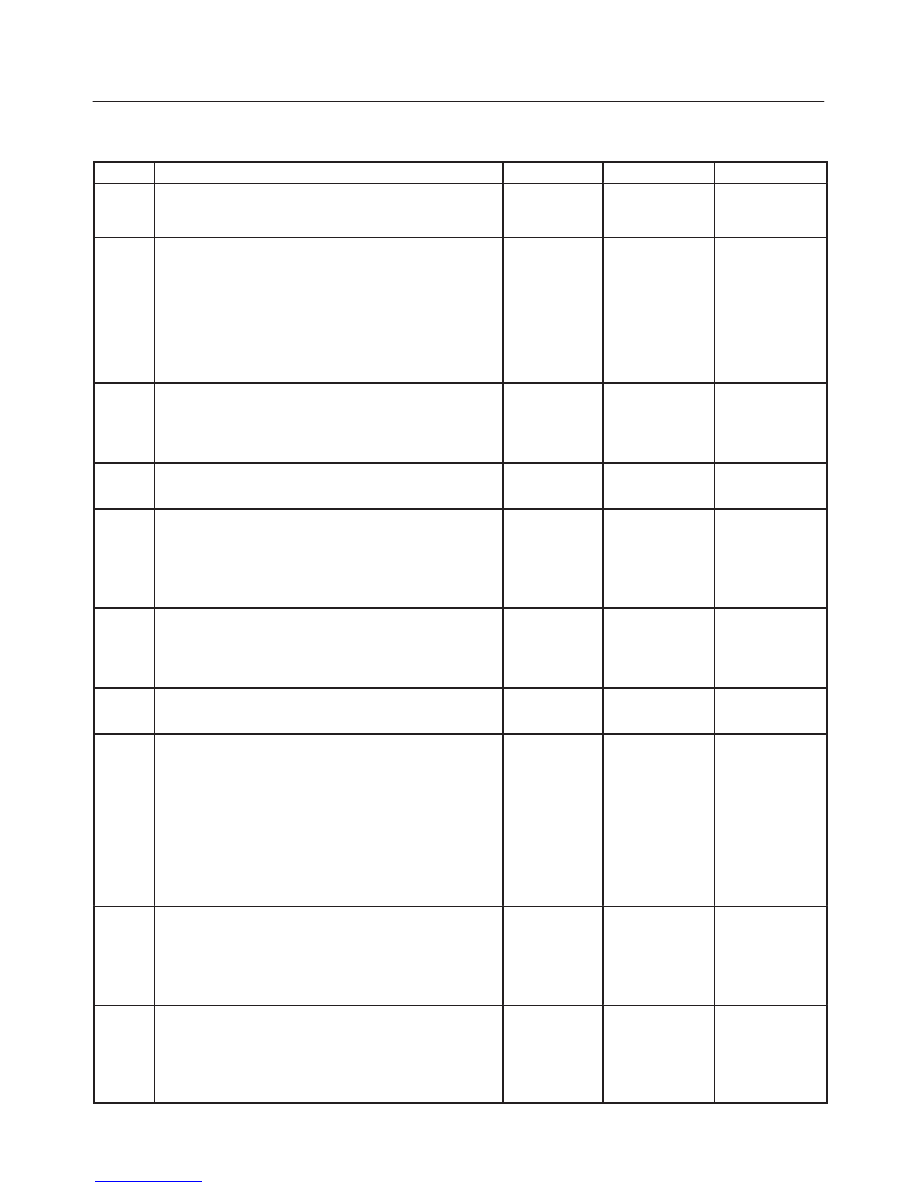

DTC P0406 – EGR High Voltage

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

1. Ignition “ON,” engine “OFF”, review and record

Tech 2 Failure Records Data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using a Tech 2, monitor “DTC” info for DTC P0406

until the DTC P0406 test runs. Note the result.

Does the Tech 2 indicates DTC P0406 failed this

ignition?

—

Go to

Step 3

Refer to

Diagnostic

Aids

3

1. Disconnect the EGR valve harness connector.

2. Inspect the EGR valve and connectors for damaged

pin or terminals.

Were there any damaged pins or terminals?

—

Go to

Step 4

Go to

Step 5

4

Repair the damaged pin or terminal.

Is the action complete?

—

Verify repair

Is the action

complete?

5

1. Disconnect the EGR harness connector.

2. Ignition “ON”.

3. At the EGR valve, use a DVM to check the voltage

at the 5 volt reference wire (RED).

Did the DVM indicate the specified value?

4–6 V

Go to

Step 8

Go to

Step 6

6

1. Ignition “ON”.

2. At the PCM connector, backprove with a DVM at the

5 volt reference for the EGR valve.

Did the DVM indicare the specified value?

4–6 V

Go to

Step 7

Go to

Step 16

7

Repair the open 5 volt reference circuit

Is the action complete?

—

Verify repair

—

8

1. Ignition “OFF”

2. Disconnect the EGR harness.

3. Use a DVM to check for an resistance between D (5

V reference) and B (Sensor Ground) at EGR sensor

terminals.

NOTE: J-35616 Connector Test Adapter Kit may be

useful for gaining access to the recessed pins on the

valve.

Was the measured resistance in range?

5 to 5 K

W

Go to

Step 9

Go to

Step 15

9

1. Ignition “OFF”.

2. Disconnect the EGR harness.

3. Use a DVM to check for an resistance between B

and C at EGR sensor terminal.

Is there an open circuit?

—

Go to

Step 15

Go to

Step 10

10

1. Ignition “OFF”.

2. Disconnect the EGR harness at PCM connector.

3. Use a DVM to check for shorted wire between A1

and B7.

Is there a shorted wire?

—

Go to

Step 14

Go to

Step 11