Isuzu Rodeo UE. Manual - part 376

6E2–259

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0303 Cylinder 3 Misfire Detected

Circuit Description

The powertrain control module (PCM) has the ability to

detect a misfire by monitoring the 58X reference and the

camshaft position sensor input signals. If the PCM

detects a crankshaft speed variation that indicates 1% or

more of cylinder firing events are misfires, the PCM will

disable the torque converter clutch (TCC). If the RPM

variation detected indicates a misfire, the PCM attempts

to calculate which cylinder is misfiring by associating

crankshaft angle (using the camshaft position sensor

signal) with the RPM variation (using the 58X reference).

If cylinder #3 is isolated as the misfiring cylinder, DTC

P0303 will set.

If the ABS Rough Road sensor input signal to the PCM

determines that a rough road condition is present, the

misfire diagnostic will be temporarily disabled.

Conditions for Setting the DTC

f

None of the following DTCs occur: TP sensor, MAF

sensor, camshaft position sensor, vehicle speed

sensor, ECT sensor, ABS rough road sensor,

crankshaft position sensor.

f

The engine speed is between 600 and 6250 RPM.

f

The system voltage is between 11 and 16 volts.

f

The ECT indicates an engine temperature between

–7

°

C (28

°

F) and 120

°

C (248

°

F).

f

The throttle angle is steady.

f

The PCM is detecting a crankshaft RPM variation that

indicates a misfire on cylinder #3 sufficient to cause

three-way catalytic converter damage or emissions

levels to exceed mandated standard.

Action Taken When the DTC Sets

f

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

f

If the misfire is severe enough to cause possible

catalyst damage, the PCM will flash the MIL for as long

as the misfire remains at catalyst damaging levels.

f

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

f

The PCM will turn the MIL “OFF” on the third

consecutive ignition cycle in which the diagnostic has

been run and the fault condition is no longer present.

f

A history DTC P0303 will clear after 40 consecutive

ignition cycles occur without a fault.

f

DTC P0303 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

f

System grounds – Ensure all connections are clean

and properly tightened.

f

Injector – Perform the injector coil/balance test to

locate a faulty injector that contributes to a lean

condition on the affected cylinder. In addition to the

above test, check the condition of the injector O-ring.

f

Faulty spark plug – Check for a cracked insulator,

carbon tracking, incorrect gap, and worn electrodes.

f

Damaged or faulty ignition coil – Check for cracks,

carbon tracking or other damage.

f

Substitute a known good coil – Swap the ignition coils

and retest. If the misfire follows the coil, replace the

ignition coil.

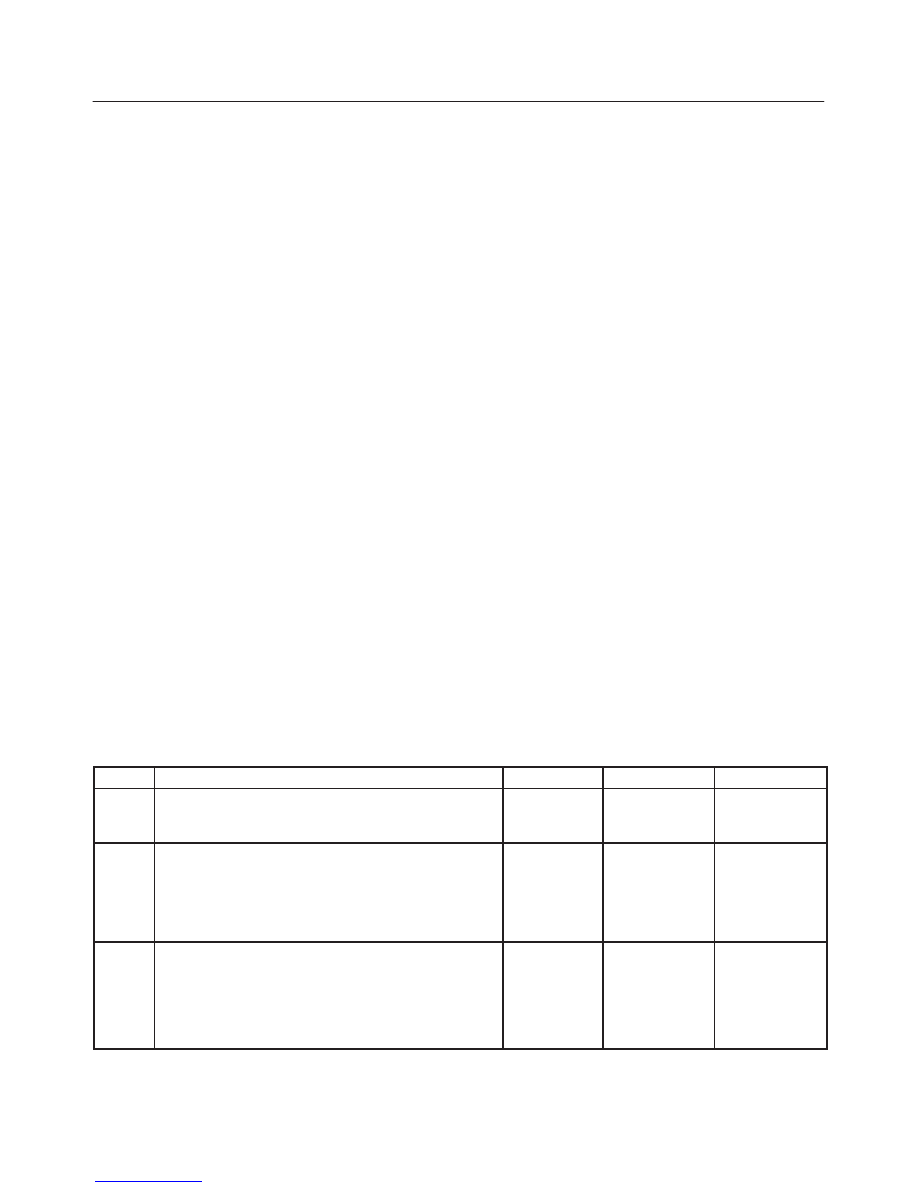

DTC P0303 — Cylinder 3 Misfire Detected

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

1. Start the engine. Run the engine at idle.

2. Review and record Tech 2 Freeze Frame data.

3. Monitor “Misfire Cur. #3” on the Tech 2.

Is “Misfire Cur. #3” increasing (indicating a misfire

currently occurring)?

—

Go to

Step 4

Go to

Step 3

3

Monitor “Misfire Hist. #3” while operating the vehicle to

duplicate the conditions present when the DTC was set

(as defined by the Freeze Frame data recorded in Step

2).

Is “Misfire Hist. #3” increasing (indicating a misfire

currently occurring)?

—

Go to

Step 4

Refer to

Diagnostic

Aids