Isuzu Rodeo UE. Manual - part 304

6D2–3

IGNITION SYSTEM (6VD1 3.2L)

Ignition Coil

Removal

1. Disconnect battery ground cable.

2. Ignition coil connector and ignition coil.

f

Disconnect three connector from ignition coil.

f

Remove harness bracket bolt on cylinder head

cover.

f

Remove fixing bolts on ignition coil.

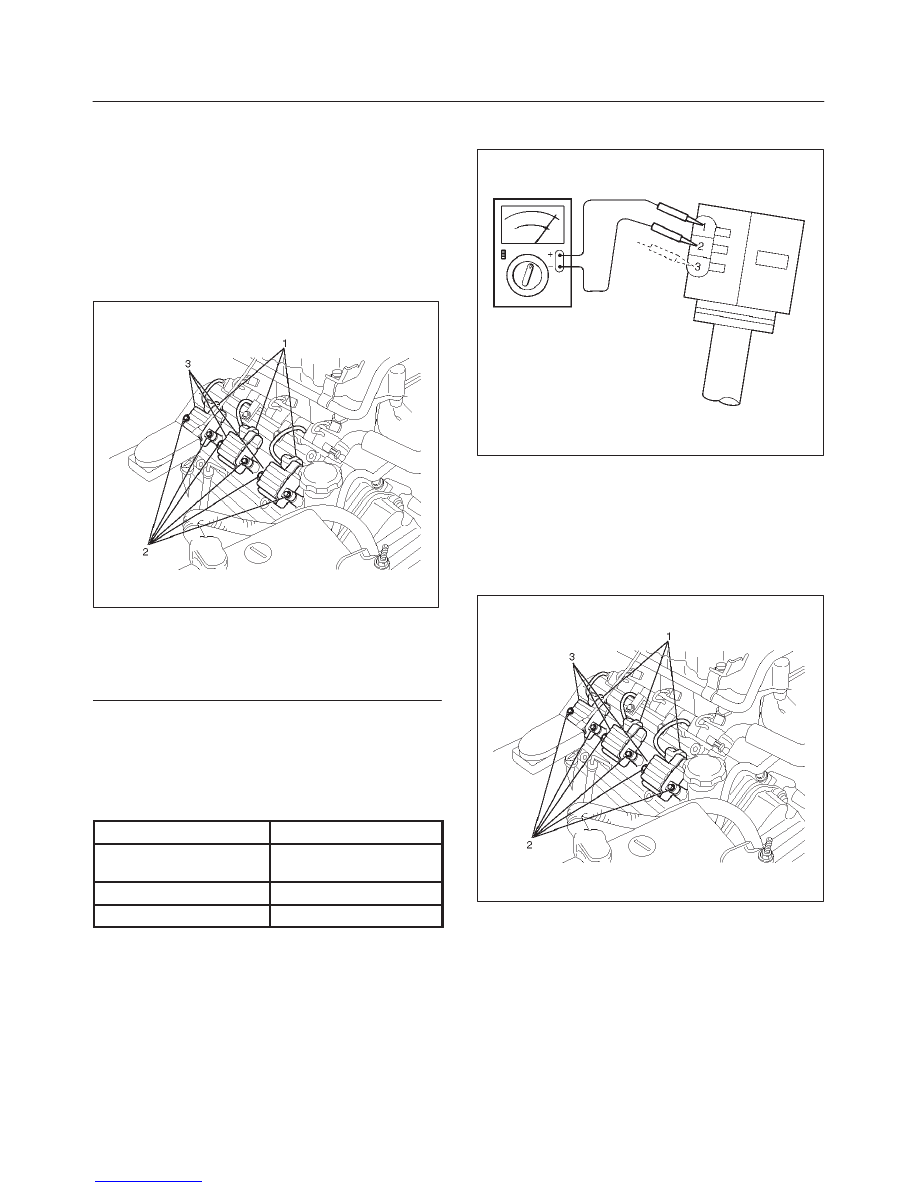

060RW001

Legend

(1) Ignition Coil Connector

(2) Bolt

(3) Ignition Coil Assembly

Inspection and Repair

Check the ignition coil assembly for insulation. Check

terminals for corrosion or damage, and replace as

necessary.

Measuring resistance of ignition coil assembly.

Terminal No.

Limit

1 to 2

Without 0 ohm or infinity

maximum ohm.

1 to 3

Same as above

2 to 3

Same as above

Measure resistance of ignition coil assembly, and replace

the ignition coil assembly if its value exceeds the

standard.

060RW006

Installation

1. Install the ignition coil assembly (3).

Connect ignition coil connector (1) and ignition coil

(3), then tighten bolt (2) to the specified torque.

Torque: 4 N·m (35 lb in)

060RW001

2. Connect battery ground cable.