Isuzu Rodeo UE. Manual - part 293

6A–85

ENGINE MECHANICAL (6VD1 3.2L)

f

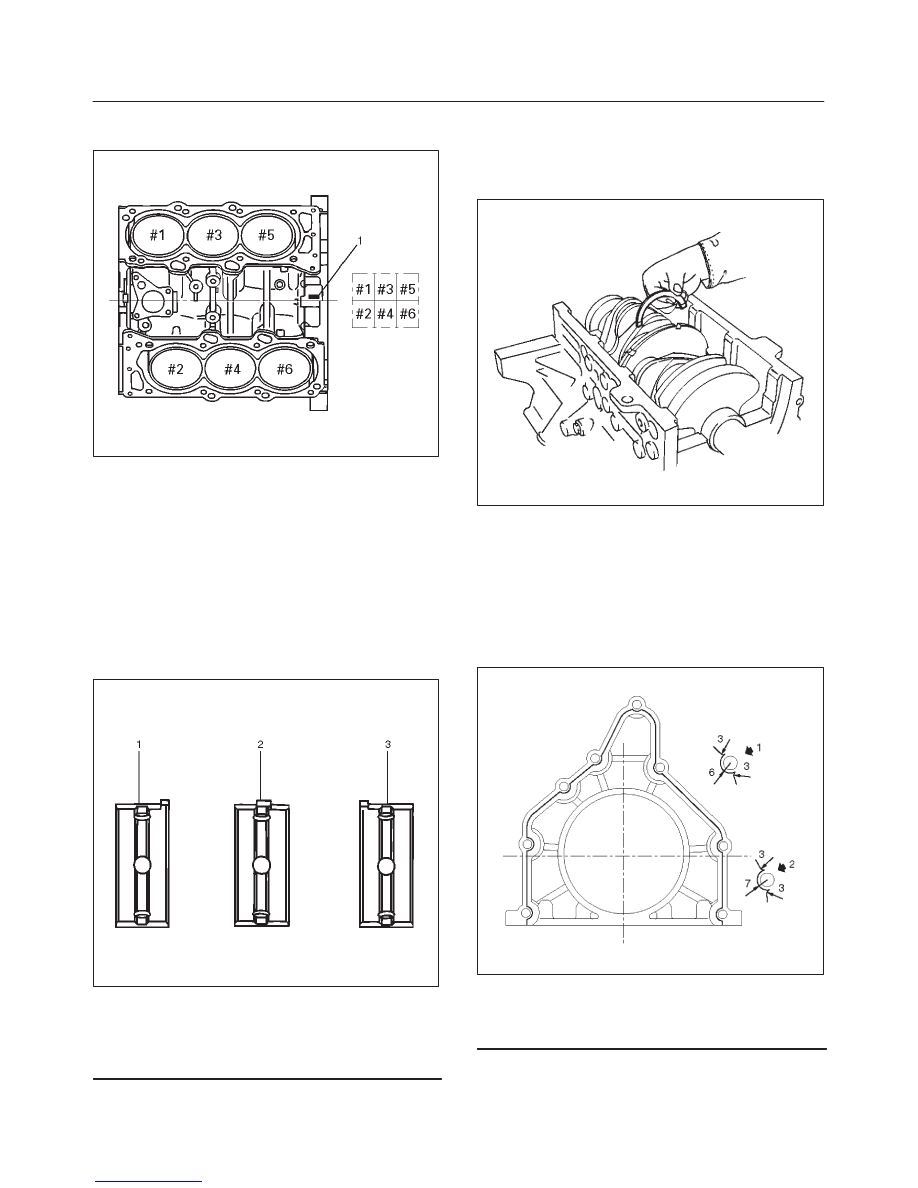

The ”Grade” mark (1) is stamped at the position

illustrated.

012RS006

Reassembly

1. Install cylinder block.

2. Install crankshaft.

f

Install the main bearings to the cylinder block and

the main bearing caps.

f

Be sure that they are positioned correctly.

f

Apply new engine oil to the upper and lower main

bearing faces.

NOTE: Do not apply engine oil to the bearing back faces.

015RS012

Legend

(1) Number 1 and 4 main bearing upper and lower.

(2) Number 2 and 3 main bearing upper.

(3) Number 2 and 3 main bearing lower.

f

Carefully mount the crankshaft.

f

Apply engine oil to the thrust washer.

f

Assemble the thrust washer to the No. 3 bearing

journal. The oil grooves must face the crankshaft.

015RS013

3. Install rear oil seal retainer.

f

Remove oil on cylinder block and retainer fitting

surface.

f

Apply sealant (TB1207B or equivalent) to retainer

fitting surface as shown in illustration.

f

The oil seal retainer must be installed within 5

minutes after sealant application to prevent

premature hardening of sealant.

015RW002

Legend

(1) Around Bolt Holes

(2) Around Dowel Pin