Isuzu Rodeo UE. Manual - part 63

DIFFERENTIAL (REAR)

4A2–17

425RW020

2. Clean all the gauge parts.

3. Lubricate the outer and inner bearings with axle

lubricant.

4. Place the bearings into the pinion bearing races.

5. Place the inner oil slinger onto the inner pinion

bearing.

NOTE: The inner oil slinger must be placed between

gauge plate and inner pinion bearing when measuring the

pinion depth.

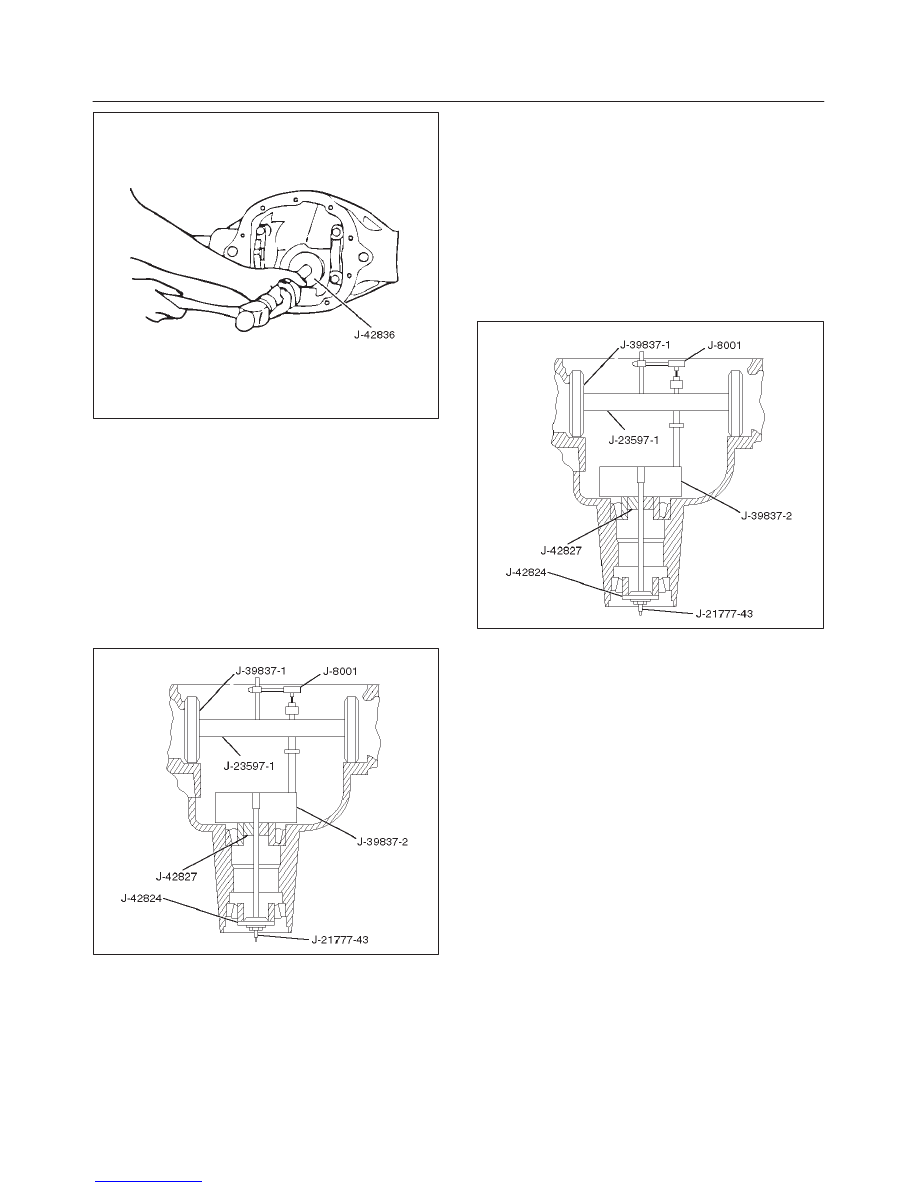

6. Install gauge plate J–39837–2, inner J–42827 stud

and nut J–21777–43 and outer pilot J–42824 to the

pinion bore.

420RW005

7. Hold the stud stationary at the flats of the stud (and).

Tighten the stud nut

Torque: 2.2 N·m (1.6 lb ft)

8. Rotate the gauge plate and bearings several

complete revolutions to seat the bearings.

9. Tighten the stud nut until a torque of 1.6 to 2.2 N·m

(1.2 to 1.6 lb ft.) is required to keep the gauge plate in

rotation.

10. Assemble discs J–39837–1, arbor J–23597–1 and

dial indicator J–8001 to the side bearing bores.

NOTE: The bearing bores must be clean and burr-free.

420RW005

11. Install the side bearing caps and tighten the bolts to

the specified torque.

Torque: 108 N·m (80 lb ft)

12. Rotate the gauge plate until the gauging area is

parallel with the discs.

13. Position the arbor assembly in the carrier so that the

plunger is centered on the gauge area of the gauge

plate.