Isuzu Rodeo UE. Manual - part 55

4A1–11

DIFFERENTIAL (FRONT)

Reassembly

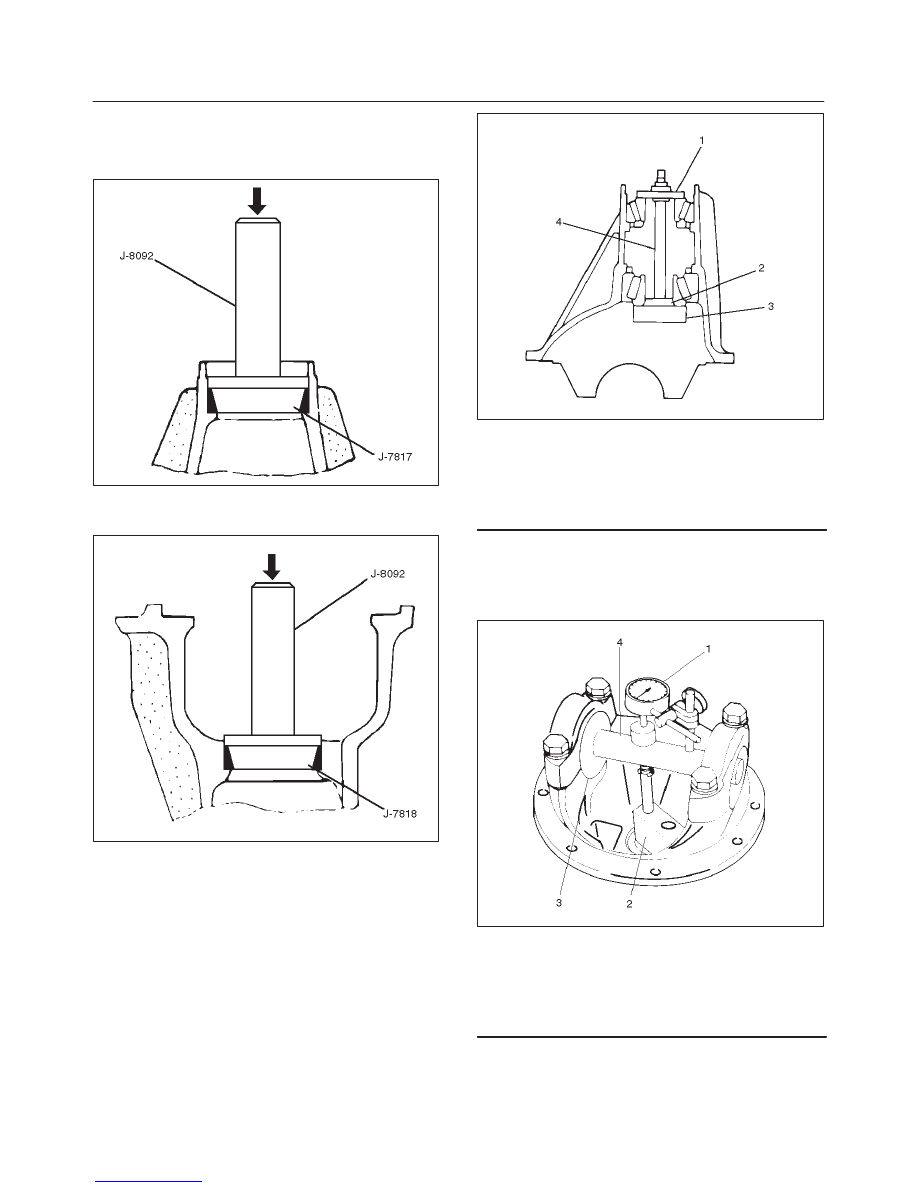

1. Using installer J–7817 and grip J–8092, install outer

bearing outer race.

415RW013

2. Using installer J–7818 and grip J–8092, install Inner

bearing outer race.

415RW014

3. Install adjust shim and adjust drive pinion mounting

distance:

1. Apply gear oil to the inner and outer drive pinion

bearing.

Clean the pinion setting gauge set.

Then install the gauge set together with the inner

and outer bearings.

2. Tighten the nut to the specified torque.

Torque: 2.3 N·m (20 lb in)

425RW030

Legend

(1) Pilot : J–21777–42

(2) Pilot : J–42479–2

(3) Gauge Plate : J–42479–1

(4) Nut and Stud : J–21777–43

3. Clean the side bearing bores. Install the dial

indicator with the discs and arbor. Install and

tighten the bearing caps to the specified torque.

Torque: 97 N·m (72 lb ft)

425RW031

Legend

(1) Dial Indicator: J–8001

(2) Gauge Plate: J–42479–1

(3) Disc (2 pcs.): J–23597–8

(4) Arbor: J–23597–1