Isuzu KB P190. Manual - part 672

Engine Mechanical – V6

Page 6A1–209

d

If the endplay exceeds the specified limits, measure the width of the crankpin end of the connecting rod, refer

to 5

Specifications.

e

If the connecting rod width is significantly smaller than specified and severe wear is present on the side of the

connecting rod, replace the connecting rod.

f

If the connecting rod width is within specification and excessive scoring is present on the crankshaft journals,

replace the crankshaft.

CAUTION

Do not use a stamp, punch or any other

method that may distort or stress the

connecting rod and cap. Extensive engine

damage may result from a connecting rod that

is distorted or stressed.

8

Mark the cylinder number on the connecting rod and the connecting rod cap with a paint stick or permanent marker.

CAUTION

Powdered metal connecting rods have rod

bolts which yield when tighten to the

specified torque. If the bolts are loosened or

removed they must be replaced. Rod bolts

that are not replaced will not torque to the

correct clamp load and can lead to serious

engine damage.

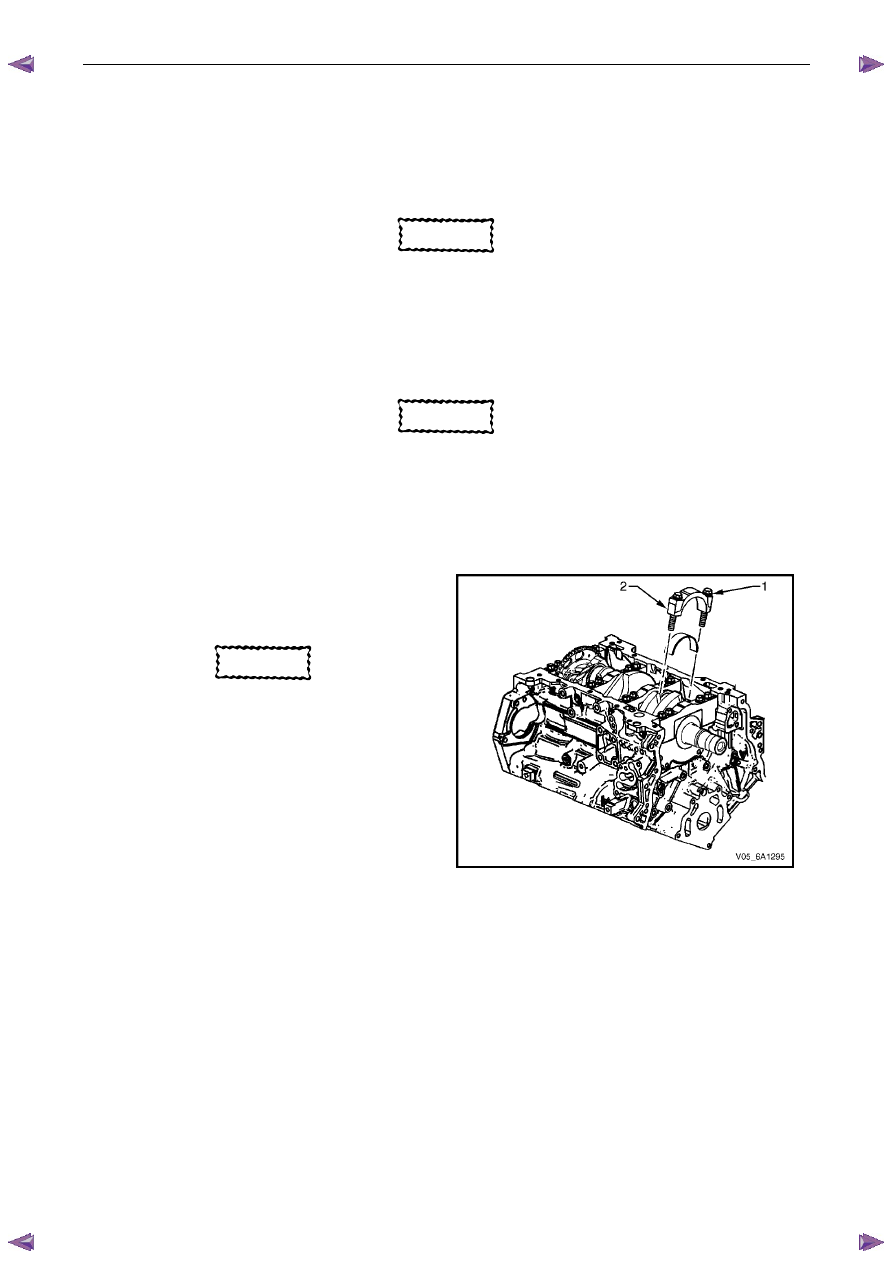

9

Remove the connecting rod bolts (1), loosening

progressively from side to side.

CAUTION

The connecting rod caps must remain with

the original connecting rod.

10

Remove the connecting rod cap (2).

Figure 6A1 – 375