Isuzu KB P190. Manual - part 484

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-319

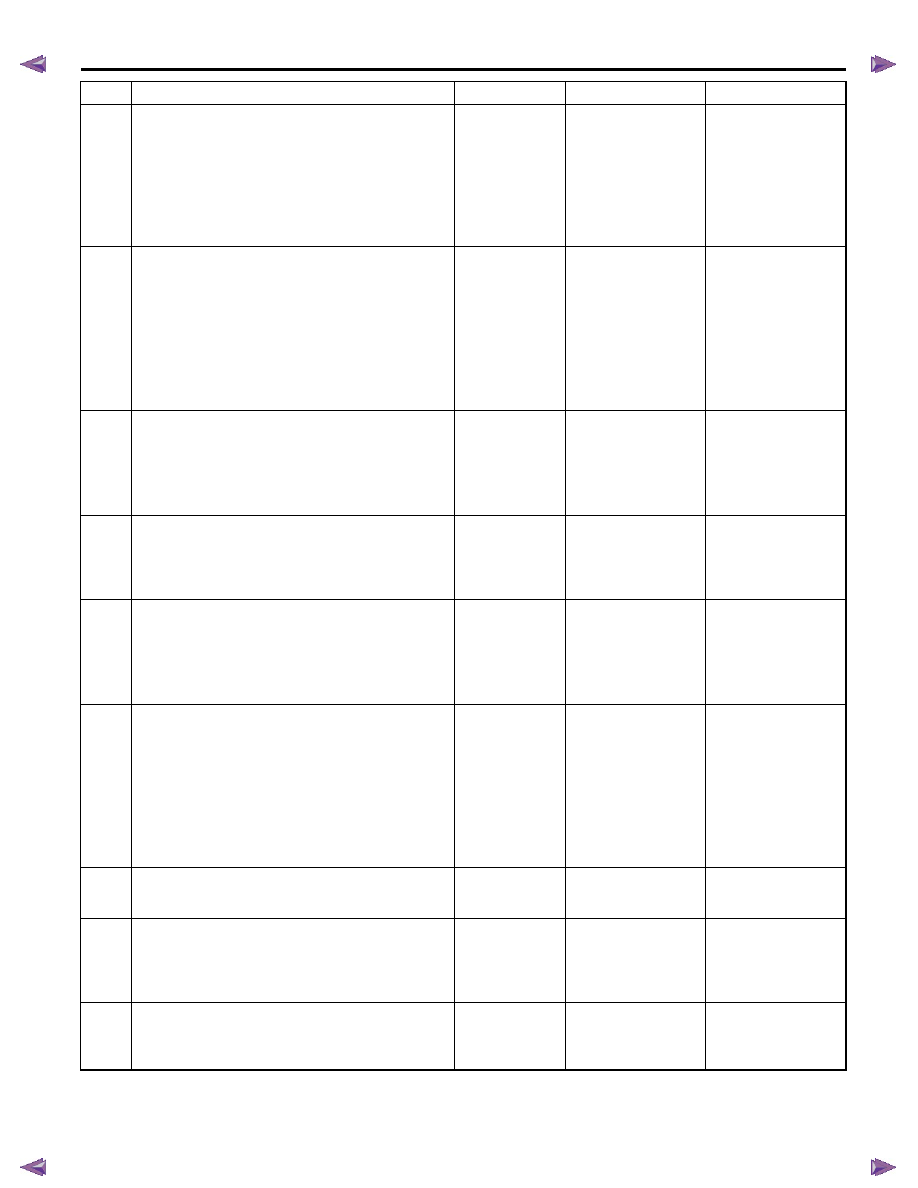

7

1.

Remove the Meter (10A) fuse that supplies

voltage to the IP cluster.

2.

Turn ON the ignition, with the engine OFF.

3.

Measure the voltage from the cruise set lamp

control circuit in the ECM harness connector

(pin 49 of C-58) to a good ground.

Is the voltage less than the specified value?

1 volt

Go to Step 8

Go to Step 10

8

1.

Turn OFF the ignition.

2.

Reinstall the Meter (10A) fuse.

3.

Turn ON the ignition, with the engine OFF.

4.

Connect a 3-amp fused jumper wire between

the cruise set lamp control circuit of the ECM

harness connector (pin 49 of C-58) and a

known good ground.

Is the cruise main lamp illuminated?

—

Go to Step 12

Go to Step 9

9

1.

Test the control circuit between the ECM (pin

49 of C-58) and the IP cluster (pin 23 of B-23)

for an open circuit or high resistance.

2.

Repair the circuit(s) as necessary.

Did you find and correct the condition?

—

Go to Step 15

Go to Step 11

10

Repair the short to battery or ignition voltage on the

control circuit between the ECM (pin 49 of C-58)

and the IP cluster (pin 23 of B-23).

Did you complete the action?

—

Go to Step 15

—

11

1.

Inspect for an intermittent and for a poor

connection at the harness connector of the IP

cluster (pins 23 of B-23).

2.

Repair the connection(s) as necessary.

Did you find and correct the condition?

—

Go to Step 15

Go to Step 13

12

1.

Turn OFF the ignition.

2.

Disconnect the ECM harness connector.

3.

Inspect for an intermittent and for poor

connections on the cruise main or set lamp

control circuit at the harness connector of the

ECM (pin 49 or 50 of C-58).

4.

Repair the connection(s) as necessary.

Did you find and correct the condition?

—

Go to Step 15

Go to Step 14

13

Repair or replace the IP cluster.

Did you complete the repair or replacement?

—

Go to Step 15

—

14

Important: Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement?

—

Go to Step 15

—

15

Reconnect all previously disconnected

components, fuse or harness connector(s).

Is the action complete?

—

Go to 1 of 2 Step 2

—

Step

Action

Value(s)

Yes

No