Isuzu KB P190. Manual - part 463

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-235

12

1.

Turn OFF the ignition.

2.

Disconnect the FRP regulator harness

connector.

3.

Inspect for an intermittent, for poor

connections and corrosion at the harness

connector of the FRP regulator (pins 1 and 2

of E-50).

4.

Disconnect the ECM harness connector.

5.

Inspect for an intermittent, for poor

connections and corrosion at the harness

connector of the ECM (pins 34, 50, 54 and 70

of E-90).

6.

Test for high resistance on each FRP regulator

circuit.

7.

Repair the connection(s) or circuit(s) as

necessary.

Did you find and correct the condition?

—

Go to Step 19

Go to Step 17

13

1.

Turn OFF the ignition.

2.

Disconnect the FRP sensor harness

connector.

3.

Inspect for an intermittent, for poor

connections and corrosion at the harness

connector of the FRP sensor (pins 1, 2 and 3

of E-48).

4.

Disconnect the ECM harness connector.

5.

Inspect for an intermittent, for poor

connections and corrosion at the harness

connector of the ECM (pins 47, 48, 68 and 69

of E-90).

6.

Test for high resistance on each circuit.

7.

Repair the connection(s) or circuit(s) as

necessary.

Did you find and correct the condition?

—

Go to Step 19

Go to Step 14

14

Replace the FRP sensor. Refer to FRP sensor

Replacement.

Did you complete the replacement?

—

Go to Step 19

—

15

Important: Replacement fuel injector must be

programmed.

Replace the appropriate fuel injector that was

leaking fuel found at Step 3 and inspect the engine

mechanical for any damage or poor engine

compression. Refer to Fuel Injector Replacement/

Fuel Injector ID Code Data Programming and

engine mechanical section.

Did you complete the replacement?

—

Go to Step 19

—

16

Important: Replacement fuel injector must be

programmed.

Replace the appropriate fuel injector that does not

change engine speed when commanded OFF.

Refer to Fuel Injector Replacement/ Fuel Injector

ID Code Data Programming.

Did you complete the replacement?

—

Go to Step 19

—

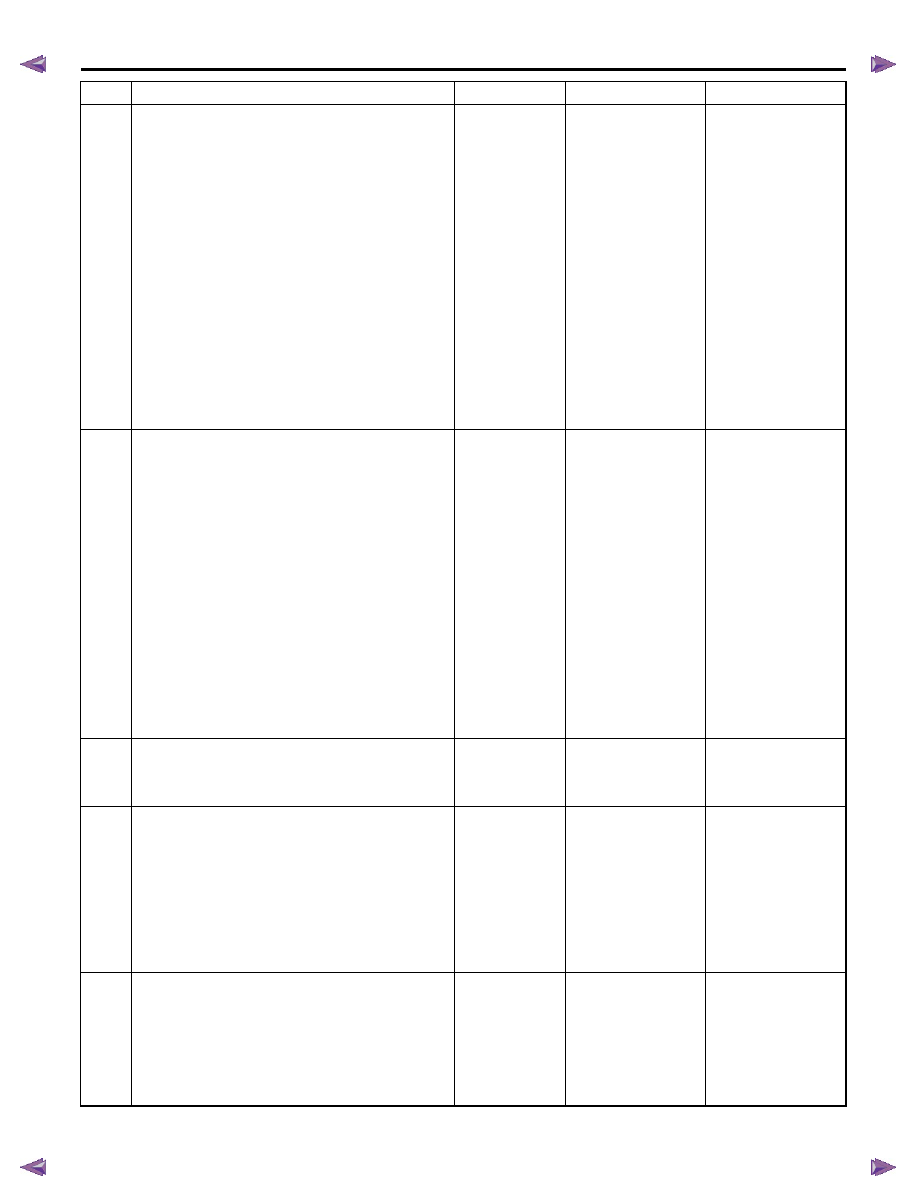

Step

Action

Value(s)

Yes

No