Isuzu KB P190. Manual - part 387

FUEL SYSTEM (4JK1/4JJ1) 6C-7

g. Check that the warning lamp in the meter is off.

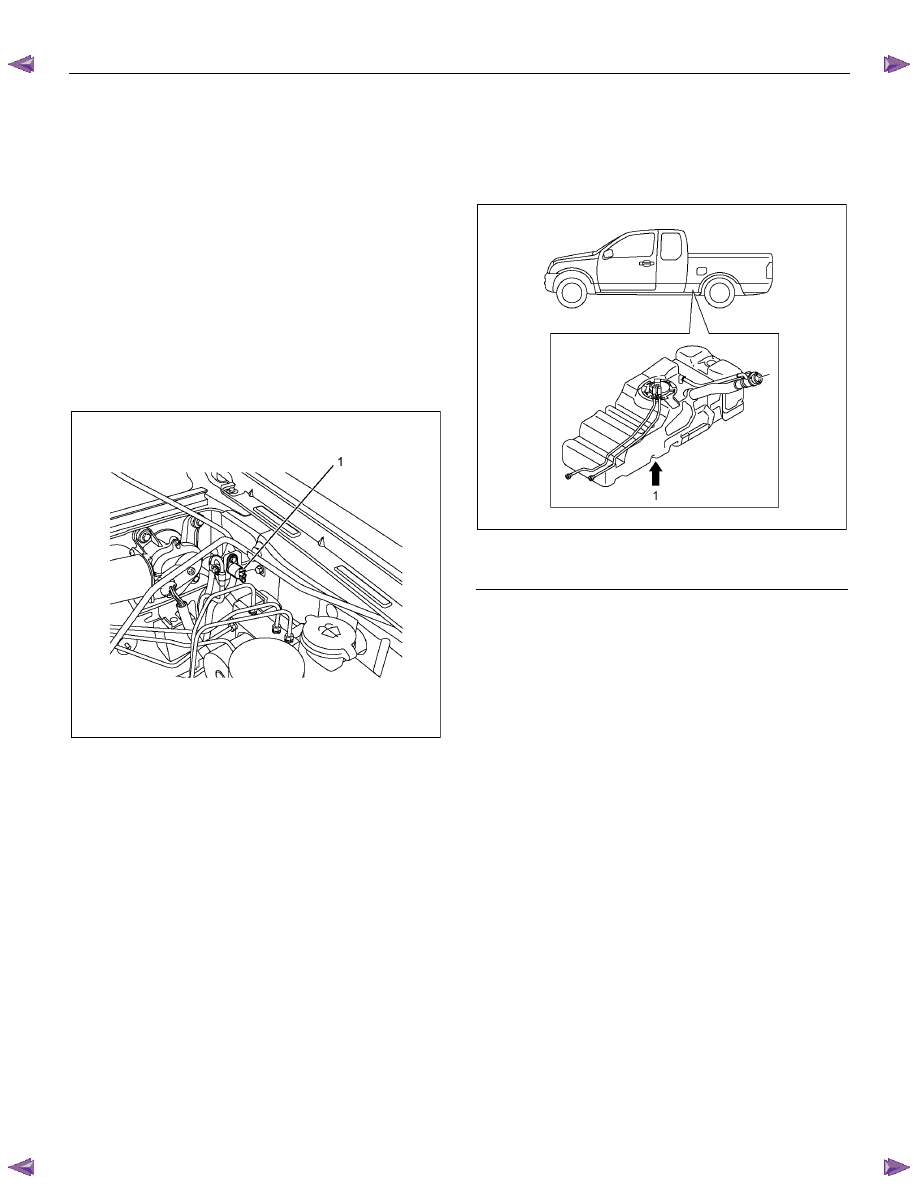

2. Draining with drain plug in engine room.

a. With the engine off, open the engine hood and

loosen the drain plug (1) located on the left

hand side of the engine room. (3-4 turns)

b. Turn the starter switch to the “ON” position for

10 seconds, and then turn the starter switch to

the “OFF” position for 10 seconds. Then, once

again turn the starter switch to the “ON”

position for 10 seconds.

c. Tighten the drain plug firmly.

d. After starting the engine, check that there is no

fuel leakage from the drain plug. Also check

that the water separator indicator has turned

off.

RTW76CSH001301

NOTE:

• If the water separator requires frequent draining,

have the fuel tank drained at your ISUZU/GM

Dealer.

• Be sure to stop the engine when draining the fuel

tank.

• Confirm that there are no combustible materials

under the drain hose, and use a receptacle to

catch the drained water.

Engine starting cautions

• Before starting the engine, turn the ignition switch

to the “ON” position. Wait 15 seconds. Return the

switch to the “LOCK” position. Repeat this

procedure 5 times.

• After starting the engine, allow it to idle for 10

minutes.

Fuel Pump Functional Check

1. Turn the starter switch to “ON” position.

2. Touch the under portion of the Fuel Tank by the

hand as shown in the following figure within 12

seconds.

RTW56CSH003501

Legend

1. Touch this area by the hand

3. Make sure a vibration by the Fuel Pump is

detected.

Fuel Pump stops within 12 seconds of turning the

starter switch to the “ON” position.

When the check is repeated, return the starter

switch to the “LOCK” position for 10 – 15 seconds

and perform procedures 1 – 3.

WARNING:

FUEL PUMP FUNCTIONAL CHECK

MUST BE CONDUCTED UNDER THE FOLLOWING

CONDITIONS TO AVOID INJURY.

•••• APPLY THE PARKING BRAKE.

•••• STOP THE ENGINE.