Isuzu KB P190. Manual - part 216

ENGINE MECHANICAL 6A – 59

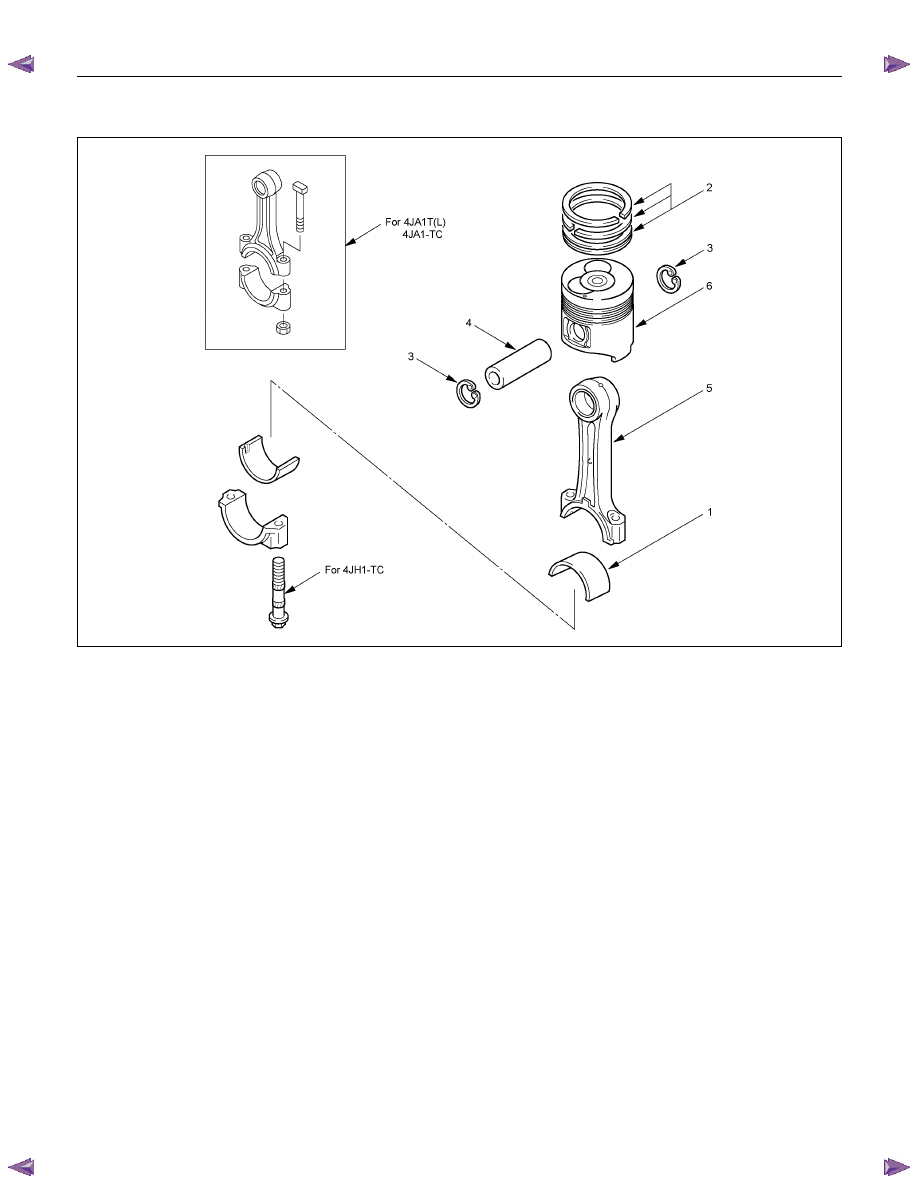

PISTON AND CONNECTING ROD

RTW46ALF000301

Disassembly Steps

1.

Connecting rod bearing

4.

Piston pin

2.

Piston ring

5.

Connecting rod

3.

Piston pin snap ring

6.

Piston

|

|

|

ENGINE MECHANICAL 6A – 59

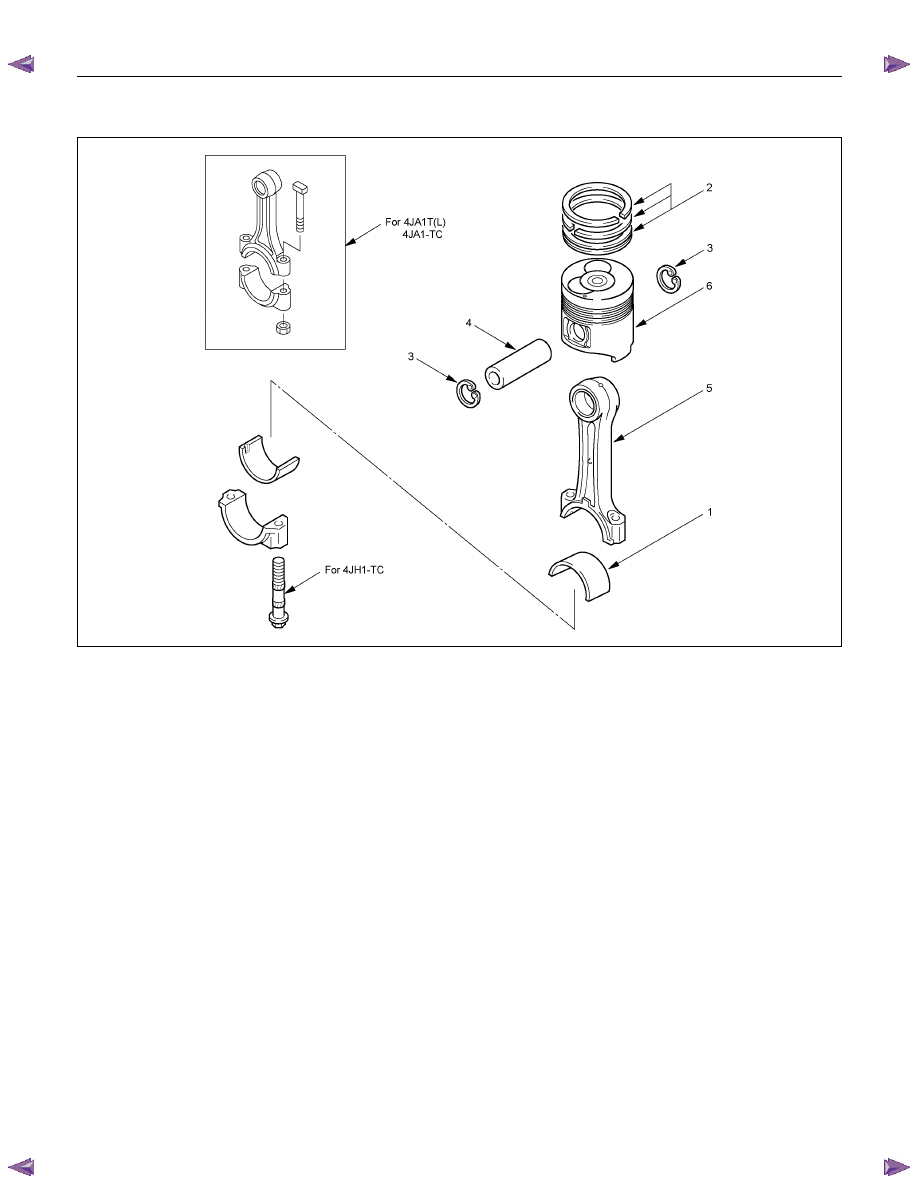

PISTON AND CONNECTING ROD

RTW46ALF000301

Disassembly Steps

1. Connecting rod bearing

4. Piston pin 2. Piston ring

5. Connecting rod 3. Piston pin snap ring

6. Piston |