Isuzu KB P190. Manual - part 154

BRAKE CONTROL SYSTEM 5A-23

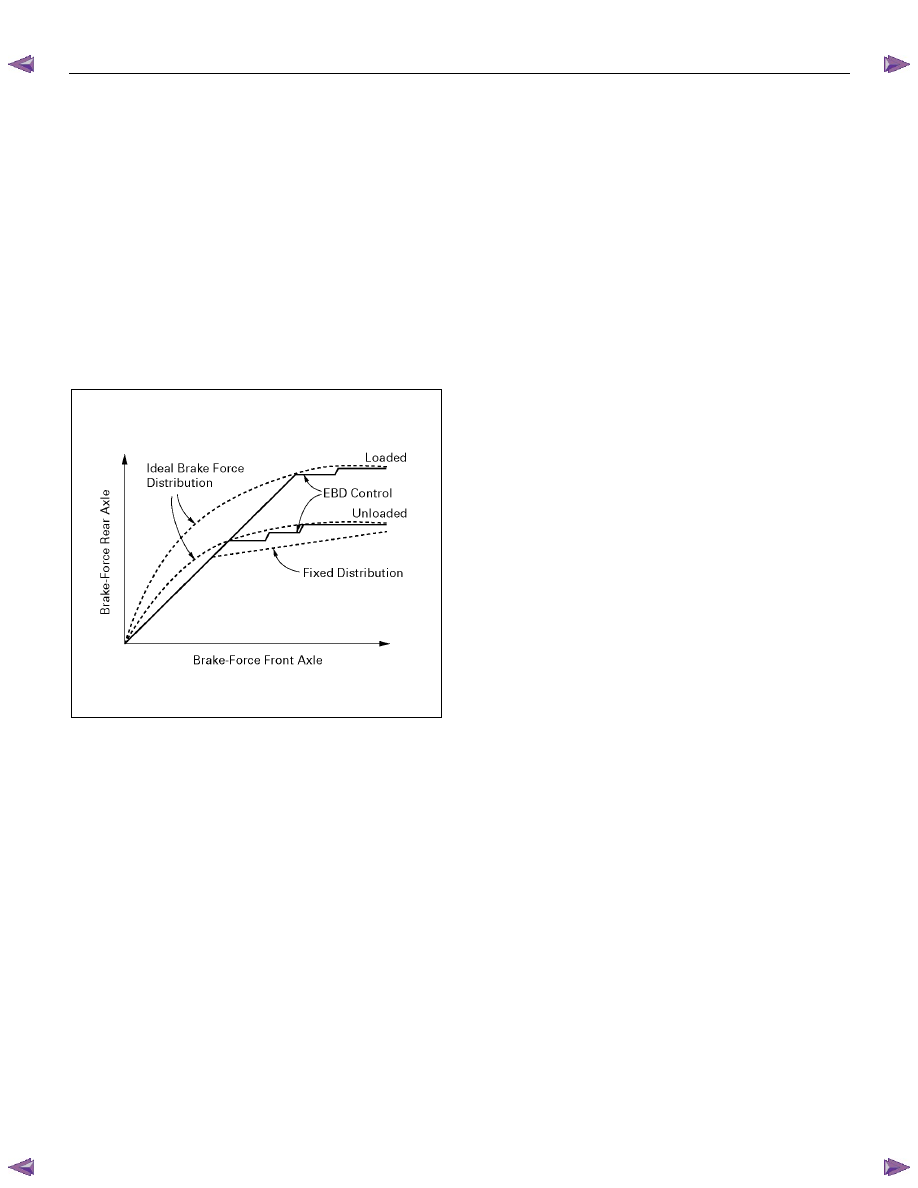

Electronic Brake-force Distribution (EBD) System

ABS has the EBD function. EBD is a function which

controls braking force distribution of a front wheel and a

rear wheel, and makes brake fluid pressure of a rear

wheel the optimal. If the rate of slip of a rear wheel

becomes greater compared to a front wheel, the brake

fluid pressure of a rear wheel will be controlled in order

to perform braking force distribution between the front

and rear wheels. EBD enables the braking power of a

rear wheel to always be utilized for the maximum

according to the load change concerning the back axis

according to the vehicle’s loading state (No luggage,

loading, etc.), deceleration, etc. Brake fluid pressure

control to a rear wheel is performed by the EBD function

which uses the ABS function without the mechanical

proportioning valve.

C05L300016

Brake Pedal Travel

Vehicles equipped with the Anti-lock Brake System may

be stopped by applying normal force to the brake pedal.

Although there is no need to push the pedal beyond the

point where it stops or holds the vehicle, by applying

more force the pedal will continue to travel toward the

floor.

This extra brake pedal travel is normal.

Acronyms and Abbreviations

Several acronyms and abbreviations are commonly

used throughout this section:

ABS

Anti-lock Brake System

CKT

Circuit

DLC

Data Link Connector

EBD

Electronic Brake-force Distribution

EHCU

Electronic Hydraulic Control Unit

FL

Front Left

FR

Front Right

GEN

Generator

H/U

Hydraulic Unit

MV

Millivolts

RR

Rear

RPS

Revolutions per Second

VDC

DC Volts

VAC

AC Volts

W/L

Warning Lamp

WSS

Wheel Speed Sensor

General Diagnosis

General Information

ABS problems can be classified into two types, those

which can be detected by the ABS warning lamp and

those which can be detected as a vehicle abnormality

by the driver.

In either case, locate the fault in accordance with the

“BASIC DIAGNOSTIC FLOWCHART” and repair.

Please refer to Section 5C for the diagnosis of

mechanical troubles such as brake noise, brake judder

(brake pedal or vehicle vibration felt when braking),

uneven braking, and parking brake trouble.

ABS Service Precautions

Required Tools and Items:

• Box Wrench

• Brake

Fluid

• Special Tool

Some diagnosis procedures in this section require the

installation of a special tool.

5-8840-0366-0 High Impedance Multimeter

When circuit measurements are requested, use a circuit

tester with high impedance.