Content .. 1040 1041 1042 1043 ..

Isuzu KB P190. Manual - part 1042

UNIT REPAIR (AW30–40LE)

7A4–33

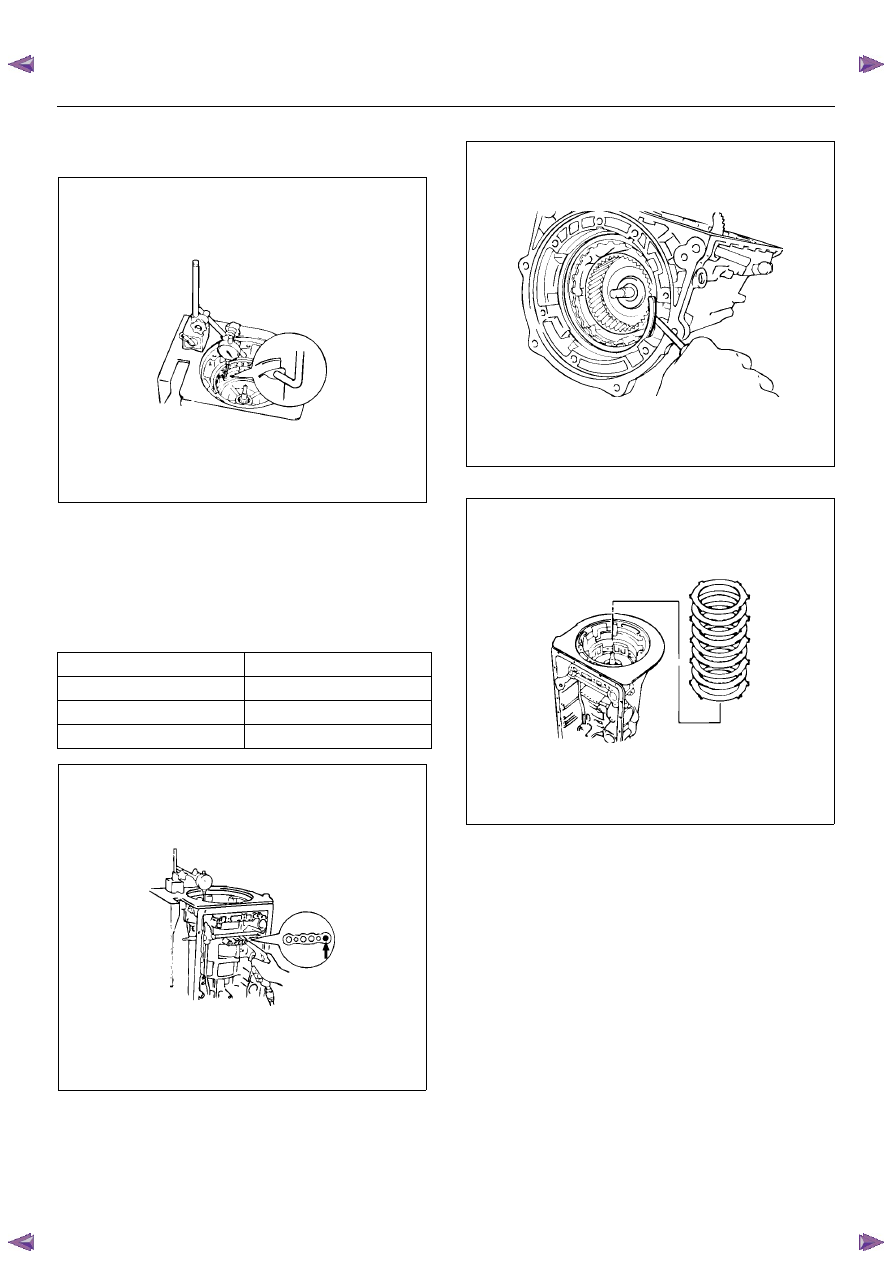

29. Check piston stroke of overdrive brake.

Place a dial indicator onto the overdrive brake

piston as shown in the figure.

252RY00003

Measure the stroke by applying and releasing the

compressed air (390 – 780 kPa or 57 – 114 psi) as

shown in the figure.

Piston stroke: 1.75 – 2.05 mm (0.0689 – 0.0807 in)

If the values are nonstandard, check for an improper

installation.

Available flange size

244RY00001

Remove the snap ring.

246RY00001

Remove one flange, four plates and four discs.

246RY00026

3.3 mm (0.130 in)

3.8 mm (0.150 in)

3.5 mm (0.138 in)

3.9 mm (0.154 in)

3.6 mm (0.142 in)

4.0 mm (0.158 in)

3.7 mm (0.146 in)