Content .. 1722 1723 1724 1725 ..

Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual - part 1724

6H-2 ENGINE SPEED CONTROL SYSTEM

Service Precaution

CAUTION:

Always use the correct fastener in the proper location.

When you replace a fastener, use ONLY the exact part

number for that application. ISUZU will call out those

fasteners that require a replacement after removal. ISUZU

will also call out the fasteners that require thread lockers

or thread sealant. UNLESS OTHERWISE SPECIFIED, do

not use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or fastener

joint interfaces. Generally, such coatings adversely affect

the fastener torque and the joint clamping force, and may

damage the fastener. When you install fasteners, use the

correct tightening sequence and specifications. Following

these instructions can help you avoid damage to parts and

systems.

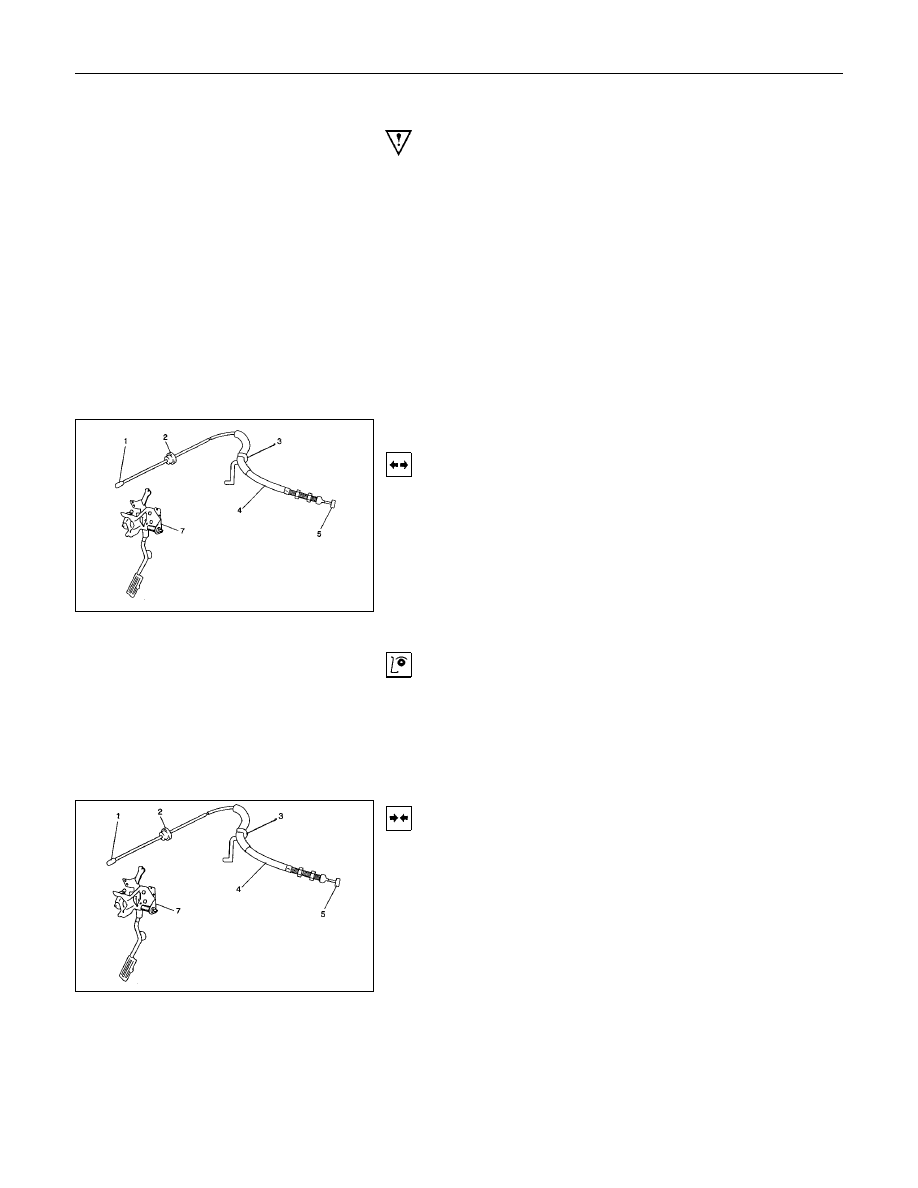

Accelerator Pedal Control Cable

Removal

1. Loosen the adjust nut on the cable bracket mounted.

2. Remove cable clip (3).

3. Disconnect accelerator pedal (AP) control cable (5). (on

throttle valve side)

4. Disconnect AP control cable (1). (on AP pedal (7) side)

5. Remove grommet (2).

6. Remove AP control cable (4).

Inspection

Check the following items, and replace the control cable if any

abnormality is found:

• The control cable should move smoothly.

• The control cable should not be bent or kinked.

• The control cable should be free of damage and corrosion.

Installation

1. Install AP control cable (4).

2. Install grommet (2).

3. Connect AP control cable (1). (on AP (7) side)

4. Connect AP control cable (5). (on throttle valve side)

5. Install cable clip (3).

6. Install adjusting nut.

7. Confirm the free play of throttle valve and control valve.

Free Play: 3 to 8 mm (0.117 to 0.312 in)