Infiniti EX37. Transaxle and Transmission (2013 year). Manual - part 13

PARKING COMPONENTS

TM-193

< REMOVAL AND INSTALLATION >

[7AT: RE7R01A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

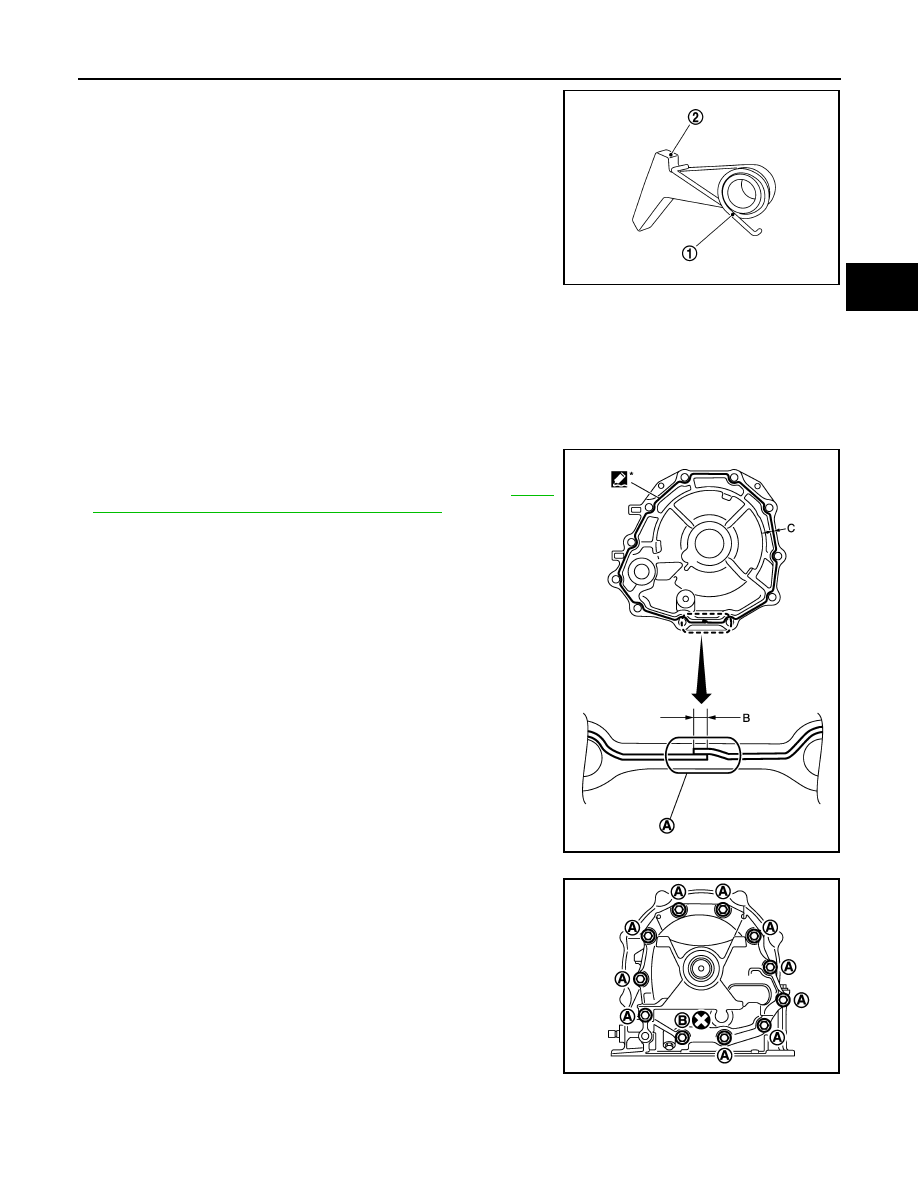

18. Remove return spring (1) from parking pawl (2).

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

• Never reuse seal rings and drain plug gasket.

• Apply petroleum jelly to needle bearing and seal rings.

• Insert the tip of parking rod between the parking pawl and the parking actuator support when assem-

bling the rear extension assembly.

• Refer to the followings installing rear extension assembly.

- Apply recommended sealant to rear extension assembly as shown

in the figure.

Use Anaerobic Liquid Gasket or an equivalent. Refer to

"Recommended Chemical Products and Sealants"

.

CAUTION:

Completely remove all moisture, oil and old sealant, etc. from

transmission case and rear extension assembly mounting

surfaces.

- Tighten rear extension assembly bolts to the specified torque.

SCIA6180J

Sealant starting

point and end-

point (A)

: Start and finish point shall be in

the center of two bolts.

Overlap width of

sealant starting

point and end-

point (B)

: 3 – 5 mm (0.12 – 0.20 in)

Sealant width (C)

: 1.0 – 2.0 mm (0.04 – 0.08 in)

Sealant height (C)

: 0.4 – 1.0 mm (0.016 – 0.04 in)

JSDIA1855ZZ

A

: Bolt

B

: Self-sealing bolt

JPDIA1138ZZ

2013 EX