Infiniti EX37. Transaxle and Transmission (2013 year). Manual - part 5

DIAGNOSIS SYSTEM (TCM)

TM-65

< SYSTEM DESCRIPTION >

[7AT: RE7R01A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

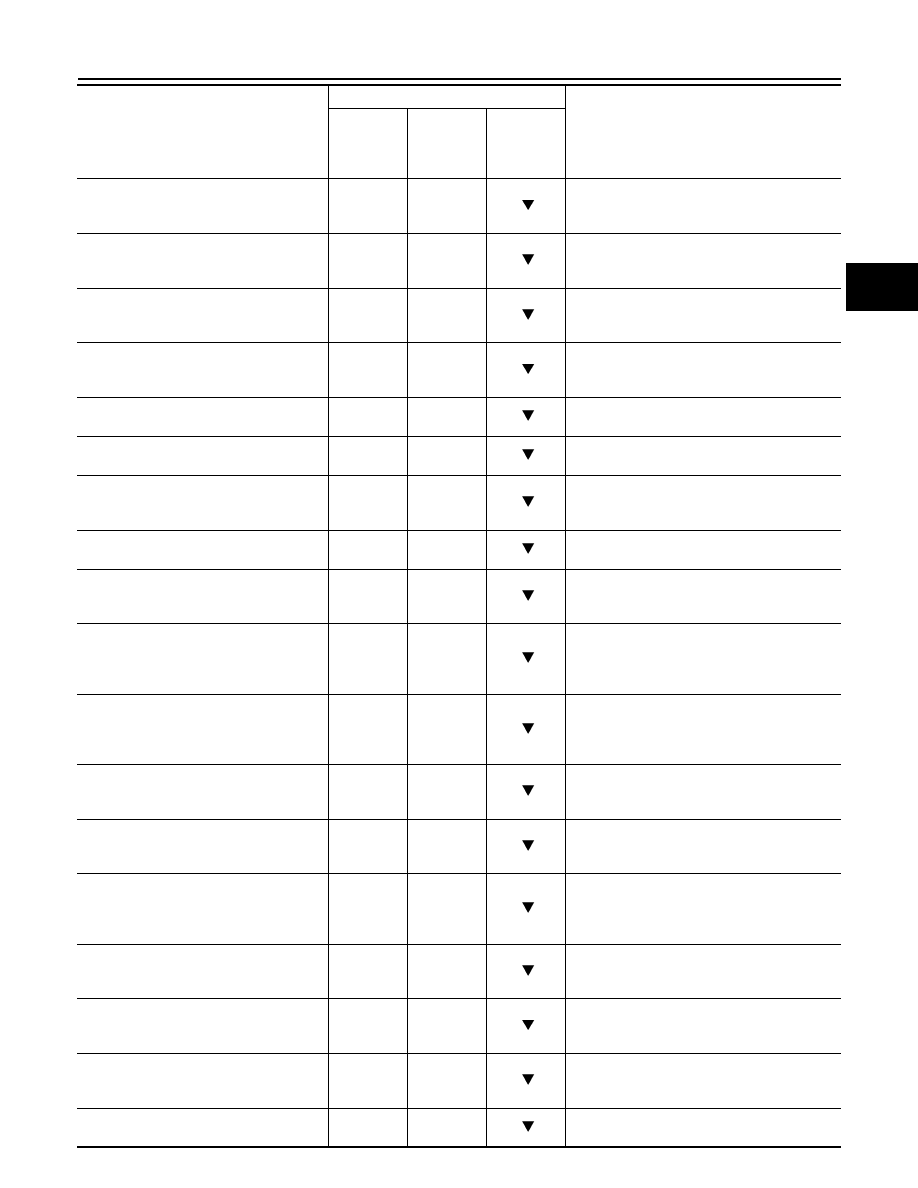

HLR/C SOL MON

(A)

—

—

Monitors the command current from TCM to the

high and low reverse clutch solenoid, and dis-

plays the monitor value.

I/C SOL MON

(A)

—

—

Monitors the command current from TCM to the

input clutch solenoid, and displays the monitor

value.

D/C SOL MON

(A)

—

—

Monitors the command current from TCM to the

direct clutch solenoid, and displays the monitor

value.

2346/B SOL MON

(A)

—

—

Monitors the command current from TCM to the

2346 brake solenoid, and displays the monitor

value.

GEAR RATIO

—

X

Displays the gear ratio calculated from input

speed and output speed.

ENGINE TORQUE

(Nm)

—

—

Displays the engine torque estimated value re-

ceived via CAN communication.

ENG TORQUE D

(Nm)

—

—

Displays the engine torque estimated value re-

flected the requested torque of each control unit

received via CAN communication.

INPUT TRQ S

(Nm)

—

—

Displays the input torque using for the oil pres-

sure calculation process of shift change control.

INPUT TRQ L/P

(Nm)

—

—

Displays the input torque using for the oil pres-

sure calculation process of line pressure con-

trol.

TRGT PRES L/P

(kPa, kg/cm

2

or psi)

—

—

Displays the target oil pressure value of torque

converter clutch solenoid valve calculated by

the oil pressure calculation process of lock-up

control.

TRGT PRES TCC

(kPa, kg/cm

2

or psi)

—

—

Displays the target oil pressure value of torque

converter clutch solenoid valve calculated by

the oil pressure calculation process of shift

change control.

TRGT PRES L/B

(kPa, kg/cm

2

or psi)

—

—

Displays the target oil pressure value of low

brake solenoid valve calculated by the oil pres-

sure calculation process of shift change control.

TRGT PRE FR/B

(kPa, kg/cm

2

or psi)

—

—

Displays the target oil pressure value of front

brake solenoid valve calculated by the oil pres-

sure calculation process of shift change control.

TRG PRE HLR/C

(kPa, kg/cm

2

or psi)

—

—

Displays the target oil pressure value of high

and low reverse clutch solenoid valve calculat-

ed by the oil pressure calculation process of

shift change control.

TRGT PRES I/C

(kPa, kg/cm

2

or psi)

—

—

Displays the target oil pressure value of input

clutch solenoid valve calculated by the oil pres-

sure calculation process of shift change control.

TRGT PRES D/C

(kPa, kg/cm

2

or psi)

—

—

Displays the target oil pressure value of direct

clutch solenoid valve calculated by the oil pres-

sure calculation process of shift change control.

TRG PRE 2346/B

(kPa, kg/cm

2

or psi)

—

—

Displays the target oil pressure value of 2346

brake solenoid valve calculated by the oil pres-

sure calculation process of shift change control.

SHIFT PATTERN

—

—

Displays the gear change data using the shift

pattern control.

Monitored item (Unit)

Monitor Item Selection

Remarks

ECU IN-

PUT SIG-

NALS

MAIN SIG-

NALS

SELEC-

TION

FROM

ITEM

2013 EX