Infiniti M45 (Y34). Manual - part 408

DTC P0340 CMP SENSOR (PHASE)

EC-321

C

D

E

F

G

H

I

J

K

L

M

A

EC

7.

CHECK CMP SENSOR (PHASE) INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1.

Disconnect ECM harness connector.

2.

Check harness continuity between ECM terminal 84 and CMP sensor (PHASE) terminal 2.

Refer to Wiring Diagram.

3.

Also check harness for short to ground or short to power.

OK or NG

OK

>> GO TO 8.

NG

>> Repair open circuit or short to ground or short to power in harness or connectors.

8.

CHECK CAMSHAFT POSITION SENSOR (PHASE)

Refer to

EC-321, "Component Inspection"

OK or NG

OK

>> GO TO 9.

NG

>> Replace camshaft position sensor (PHASE).

9.

CHECK INTERMITTENT INCIDENT

Refer to

EC-132, "TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT"

>> INSPECTION END

Component Inspection

ABS002JU

CAMSHAFT POSITION SENSOR (PHASE)

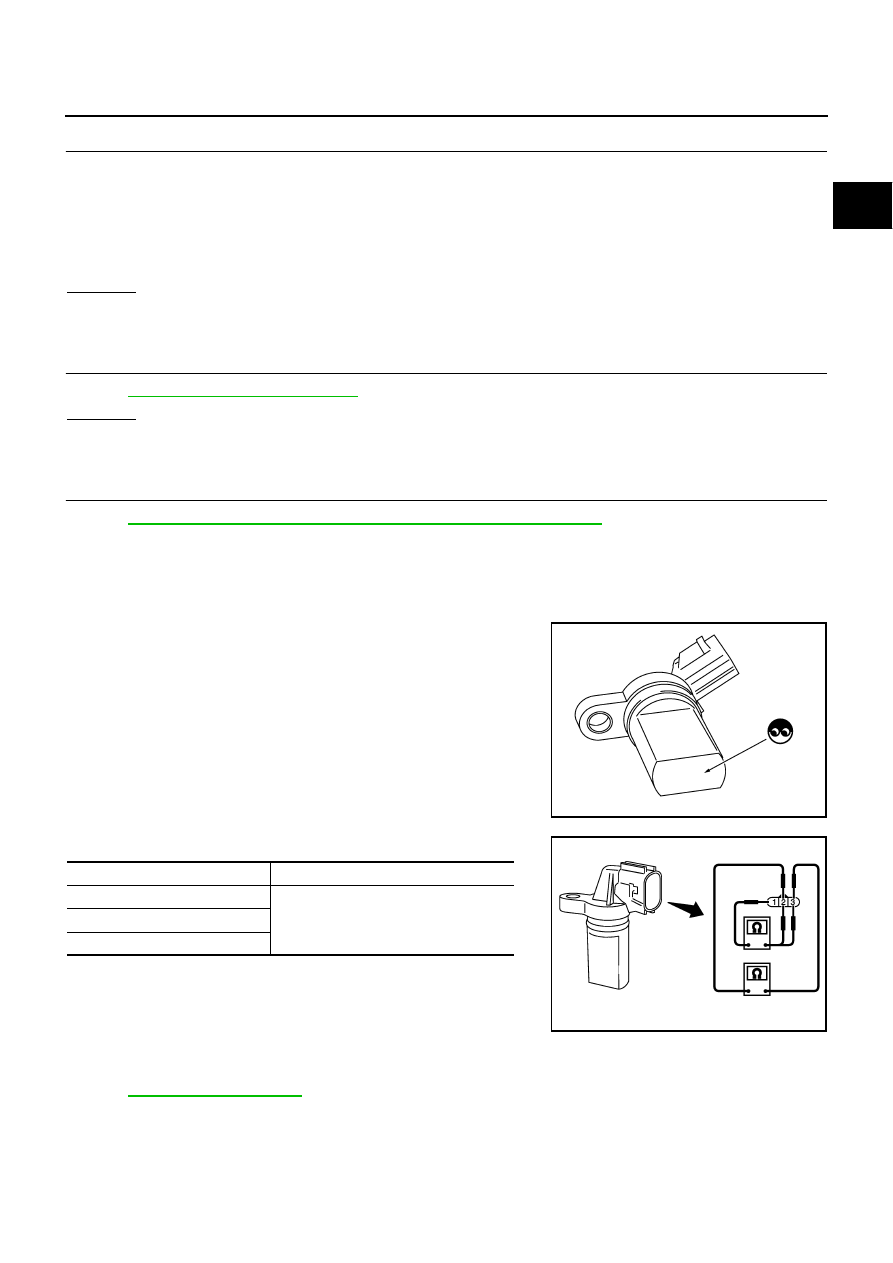

1.

Loosen the fixing bolt of the sensor.

2.

Disconnect camshaft position sensor (PHASE) harness connec-

tor.

3.

Remove the sensor.

4.

Visually check the sensor for chipping.

5.

Check resistance as shown in the figure.

Removal and Installation

ABS002JV

CAMSHAFT POSITION SENSOR (PHASE)

Refer to

Continuity should exist.

PBIB0563E

Terminal No. (Polarity)

Resistance

Ω

[at 25

°

C (77

°

F)]

1 (+) - 2 (-)

Except 0 or

∞

1 (+) - 3 (-)

2 (+) - 3 (-)

PBIB0564E