Infiniti M35/M45 Y50. Manual - part 994

FRONT PROPELLER SHAFT

PR-5

C

E

F

G

H

I

J

K

L

M

A

B

PR

Removal and Installation

NDS000EC

REMOVAL

1.

Remove engine undercover with a power tool.

2.

If necessary, remove heat bracket.

3.

Remove the three way catalyst (right bank) with a power tool. Refer to

4.

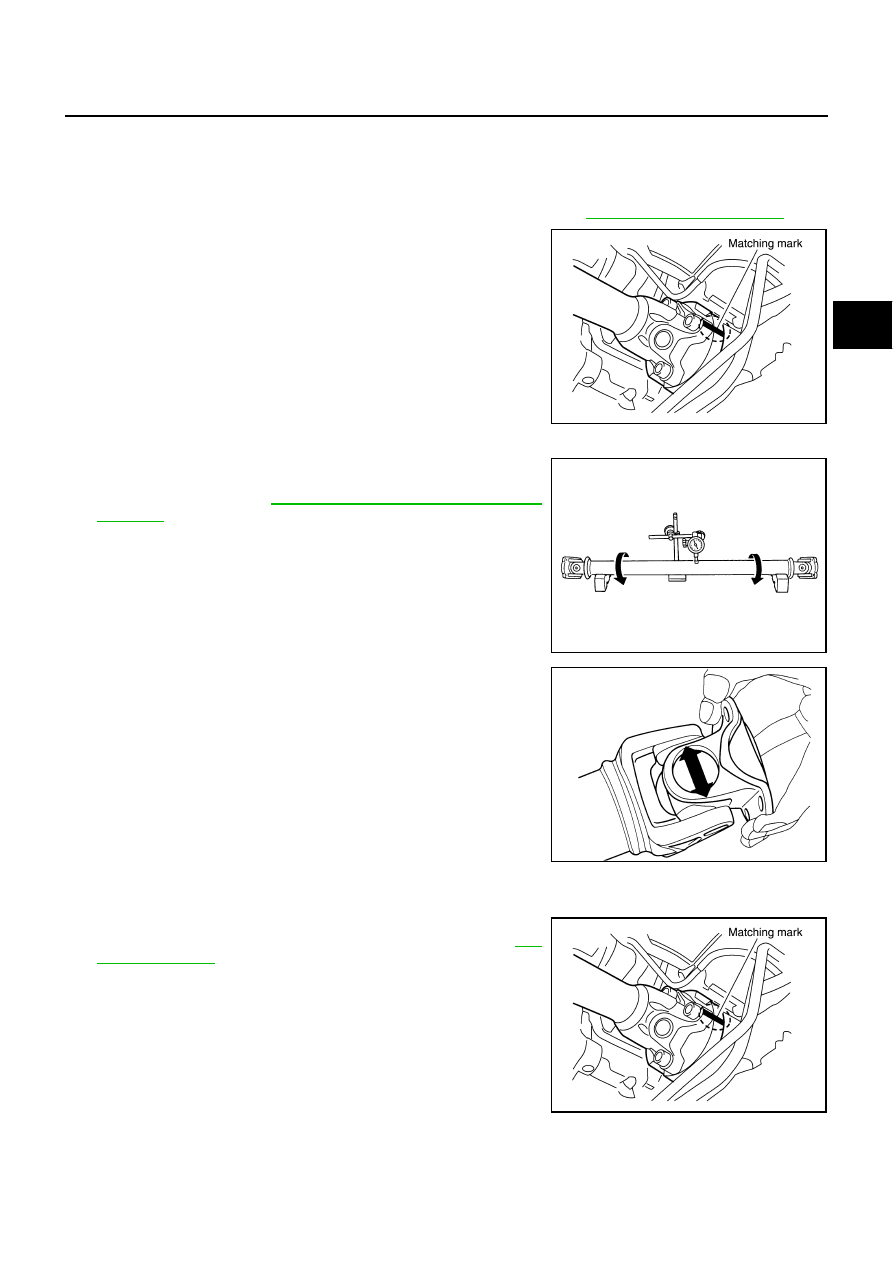

Put matching marks onto propeller shaft flange yoke and final

drive companion flange.

CAUTION:

For matching marks, use paint. Do not damage propeller

shaft flange and companion flange.

5.

Remove the propeller shaft fixing bolts.

6.

Remove propeller shaft from the front final drive and transfer.

INSPECTION

●

Inspect propeller shaft runout at measuring point. If runout

exceeds specifications, replace propeller shaft assembly. For

measuring point, refer to

PR-4, "Propeller Shaft Runout Measur-

●

As shown in the figure, while fixing yoke on one side, check axial

play of joint. If outside the standard, replace propeller shaft

assembly.

●

Check propeller shaft for bend and damage. If damage is

detected, replace propeller shaft assembly.

CAUTION:

Do not disassemble joints.

INSTALLATION

Note the following, install in the reverse order of removal.

●

Align matching marks to install propeller shaft to final drive com-

panion flange, and then tighten to specified torque. Refer to

CAUTION:

Do not reuse the bolts.

●

After assembly, perform a driving test to check propeller shaft

vibration. If vibration occurred, separate propeller shaft from

final drive or transfer. Reinstall companion flange after rotating it

by 90, 180, 270 degrees. Then perform driving test and check

propeller shaft vibration again at each point.

SDIA1517E

Propeller shaft runout limit

: 0.8 mm (0.031 in)

SPD106

Journal axial play

: 0 mm (0 in)

PDA0005D

SDIA1517E