Infiniti G35 (V35). Manual - part 744

SE-78

AUTOMATIC DRIVE POSITIONER

Check UART Communication Line Circuit

NIS001IG

1.

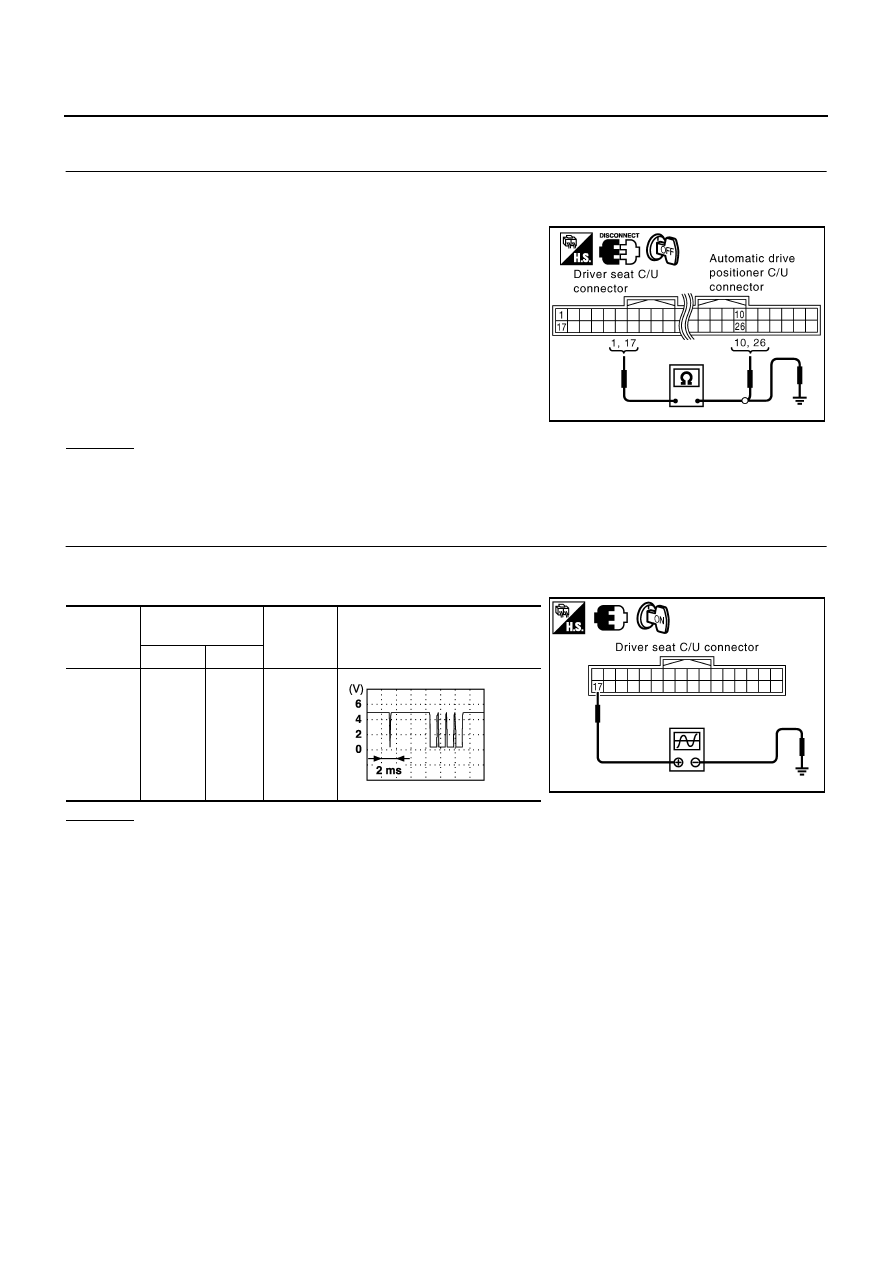

CHECK UART LINE HERNESS

1.

Turn ignition switch OFF.

2.

Disconnect driver seat control unit connector and automatic drive positioner control unit connector.

3.

Check continuity between driver seat control unit connector

B352 terminal 1, 17 and automatic drive positioner connector

M96 terminal 10, 26.

4.

Check continuity between driver seat control unit connector

B352 terminal 1, 17 and ground.

OK or NG

OK

>> GO TO 2.

NG

>> Repair or replace harness between driver seat control unit and automatic drive positioner control

unit.

2.

CHECK UART LINE SIGNAL 1

1.

Turn ignition switch ON.

2.

Check signal between driver seat control unit connector ground, with oscilloscope.

OK or NG

OK

>> GO TO 3.

NG

>> Check the flowing.

●

When voltage signal does not appear with a constant voltage (approx. 5V), replace driver seat

control unit.

●

When voltage signal does not appear with a constant voltage (approx. 0V), replace automatic

drive positioner control unit.

17 (R/Y)

−

26 (R/G)

: Continuity should exist.

1 (L/W)

−

10 (R/L)

: Continuity should exist.

17 (R/Y)

−

Ground

: Continuity should not exist.

1 (L/W)

−

Ground

: Continuity should not exist.

PIIB3418E

Connector

Terminals

(Wire color)

Condition

Signal

(Reference value)

(+)

(–)

B352

17 (R/Y)

Ground

Seat

memory

switch 1 or

2 opera-

tion

PIIB7644E

PIIA4814E