Infiniti G35 (V35). Manual - part 737

SE-50

AUTOMATIC DRIVE POSITIONER

4.

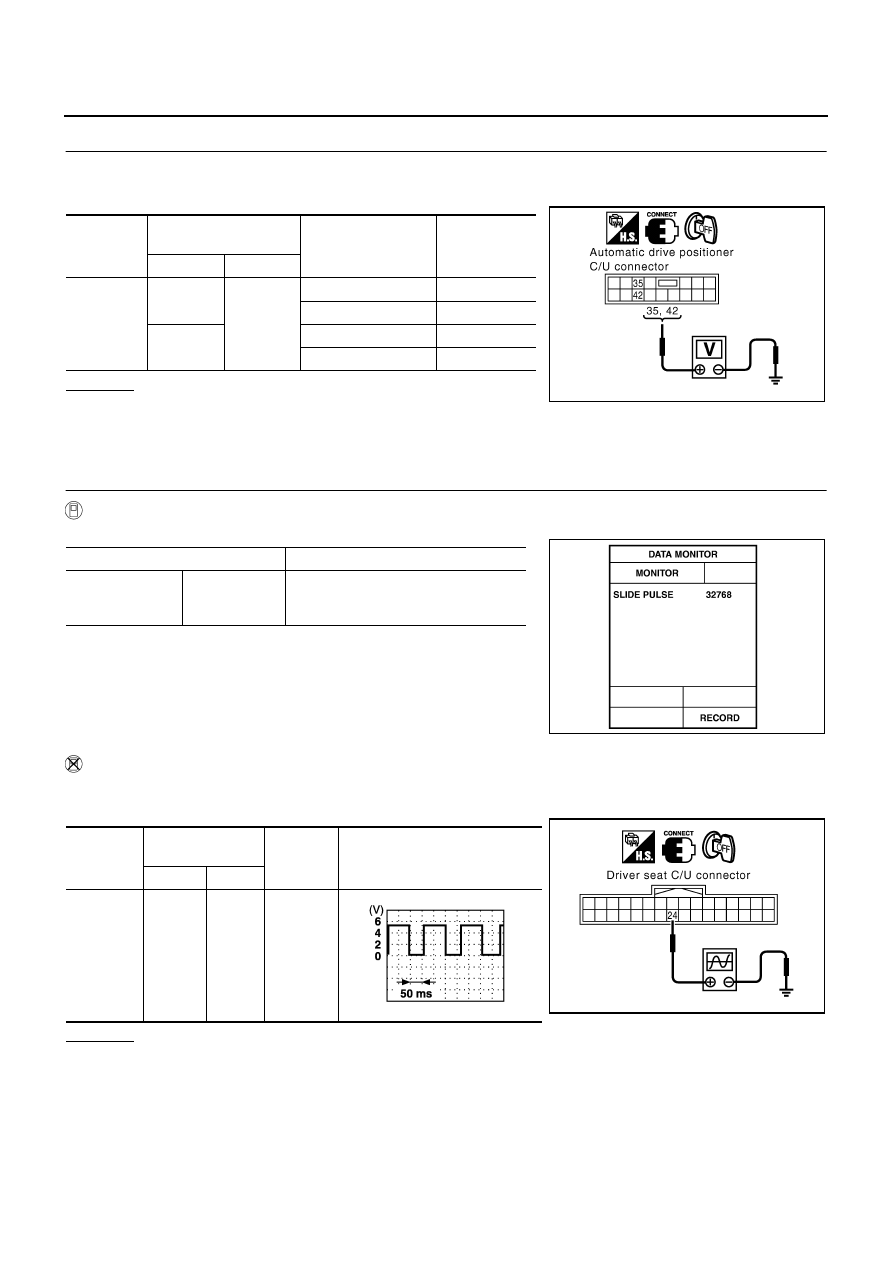

CHECK BCM OUTPUT SIGNAL

1.

Connect automatic drive positioner control unit connector and tilt and telescopic motor connector.

2.

Tilt switch operate, check voltage between automatic drive positioner control unit connector and ground.

OK or NG

OK

>> Replace tilt and telescopic motor.

NG

>> Replace automatic drive positioner control unit.

Check Sliding Sensor Circuit

NIS001HT

1.

CHECK FUNCTION

With CONSULT-II

Check operation with “SLIDE PULSE” on the DATA MONITOR to make sure the pulse changes.

Without CONSULT-II

1.

Turn ignition switch OFF.

2.

Check signal between driver seat control unit connector and ground, with oscilloscope.

OK or NG

OK

>> Sliding sensor circuit is OK.

NG

>> GO TO 2.

Connector

Terminals

(Wire color)

Tilt switch condition

Voltage (V)

(Approx.)

(+)

(–)

M97

35 (G/Y)

Ground

UP

Battery voltage

Other than above

0

42 (G/W)

DOWN

Battery voltage

Other than above

0

PIIA5067E

Monitor item [OPERATION or UNIT]

Contents

SLIDE PULSE

—

The seat sliding position (pulse) judged

from the sliding sensor signal is dis-

played.

PIIB2040E

Connector

Terminals

(Wire color)

Condition

Signal

(Reference value)

(+)

(–)

B352

24 (R)

Ground

Sliding

motor

operation

PIIA4556E

PIIA3277E