Infiniti G35 (V35). Manual - part 625

LU-14

OIL PUMP

INSPECTION AFTER DISASSEMBLY

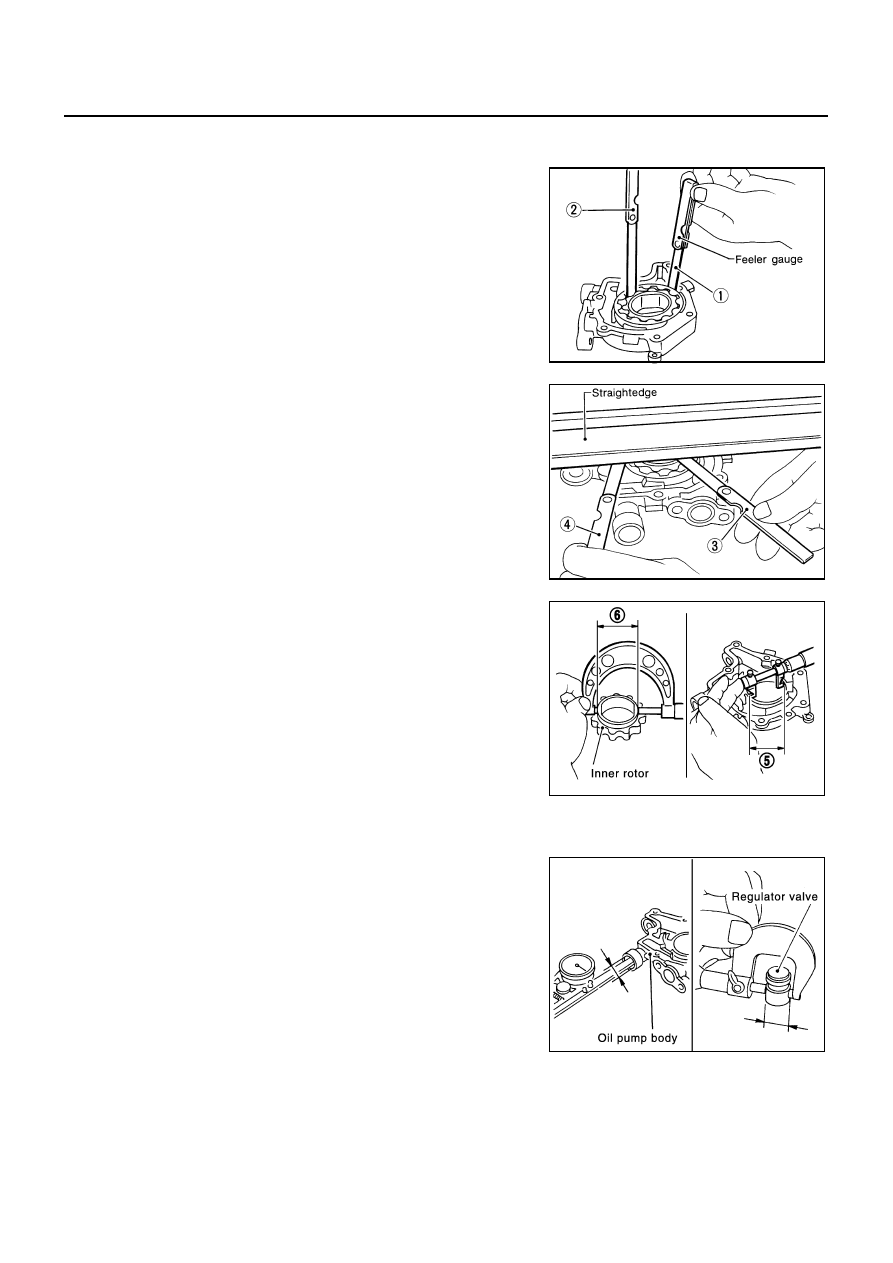

Clearance of Oil Pump Parts

●

Measure the clearance with feeler gauge.

–

Clearance between outer rotor and oil pump body (position 1)

–

Tip clearance between inner rotor and outer rotor (position 2)

●

Measure the clearance with feeler gauge and straightedge.

–

Side clearance between inner rotor and oil pump body (position

3)

–

Side clearance between outer rotor and oil pump body (position

4)

●

Calculate the clearance between inner rotor and oil pump body

as follows:

–

Measure the inner diameter of oil pump body with inside

micrometer (Position 5)

–

Measure the outer diameter of protruded portion of inner rotor

with micrometer (Position 6)

–

(Clearance) = (Inner diameter of oil pump body) – (Outer diame-

ter of inner rotor)

●

If measured/calculated values are out of the standard, replace

oil pump assembly.

Regulator Valve Clearance

(Clearance) = (Valve hole diameter) – (Regulator valve outer diame-

ter)

●

If out of the standard, replace oil pump assembly.

CAUTION:

●

Coat regulator valve with engine oil.

●

Make sure that it falls smoothly into valve hole by its own

weight.

Standard

: 0.114 - 0.260 mm (0.0045 - 0.0102 in)

Standard

: Below 0.180 mm (0.0071 in)

SLC932A

Standard

: 0.030 - 0.070 mm (0.0012 - 0.0028 in)

Standard

: 0.050 - 0.110 mm (0.0020 - 0.0043 in)

SLC933A

Standard

: 0.045 - 0.091 mm (0.0018 - 0.0036 in)

PBIC0821E

Standard

: 0.040 - 0.097 mm (0.0016 - 0.0038 in)

PBIC0822E