Infiniti G35 (V35). Manual - part 495

ENGINE ASSEMBLY

EM-135

C

D

E

F

G

H

I

J

K

L

M

A

EM

●

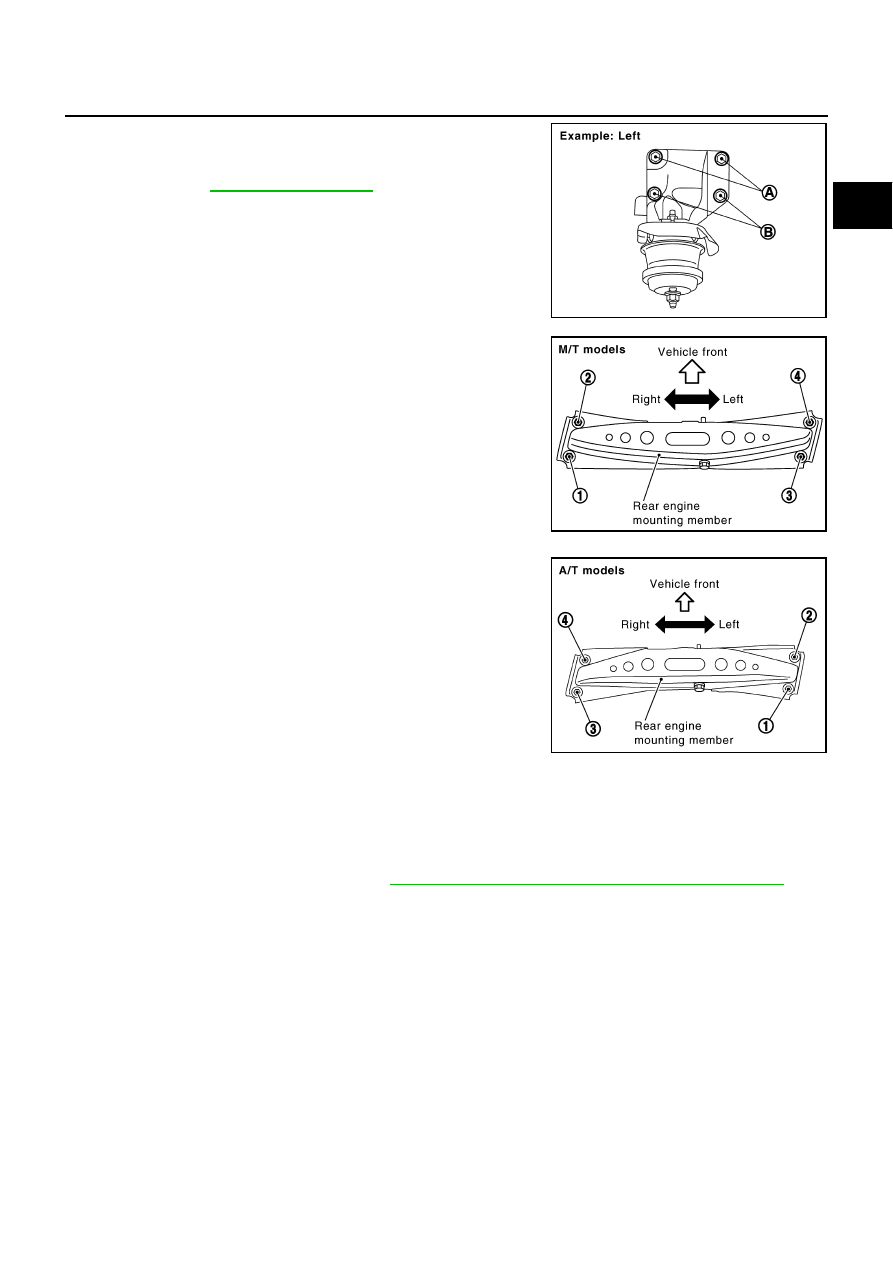

For a location with a positioning pin, insert it securely into hole of

mating part.

●

For a part with a specified installation orientation, refer to com-

ponent figure in

●

When installing engine mounting brackets (RH and LH) on cylin-

der block, tighten two upper bolts (shown as “A” in the figure)

first. Then tighten two lower bolts (shown as “B” in the figure).

●

Tighten rear engine mounting member bolts in numerical order

as shown in the figure.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak and exhaust gases leak.

●

Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to

MA-10, "RECOMMENDED FLUIDS AND LUBRICANTS"

●

Use procedure below to check for fuel leakage.

–

Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel

leakage at connection points.

–

Start engine. With engine speed increased, check again for fuel leakage at connection points.

●

Run engine to check for unusual noise and vibration.

●

Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gases, or any oil/fluids

including engine oil and engine coolant.

●

Bleed air from lines and hoses of applicable lines, such as in cooling system.

●

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

PBIC2062E

PBIC1684E

PBIC1683E