Infiniti G35 (V35). Manual - part 490

CAMSHAFT

EM-115

C

D

E

F

G

H

I

J

K

L

M

A

EM

●

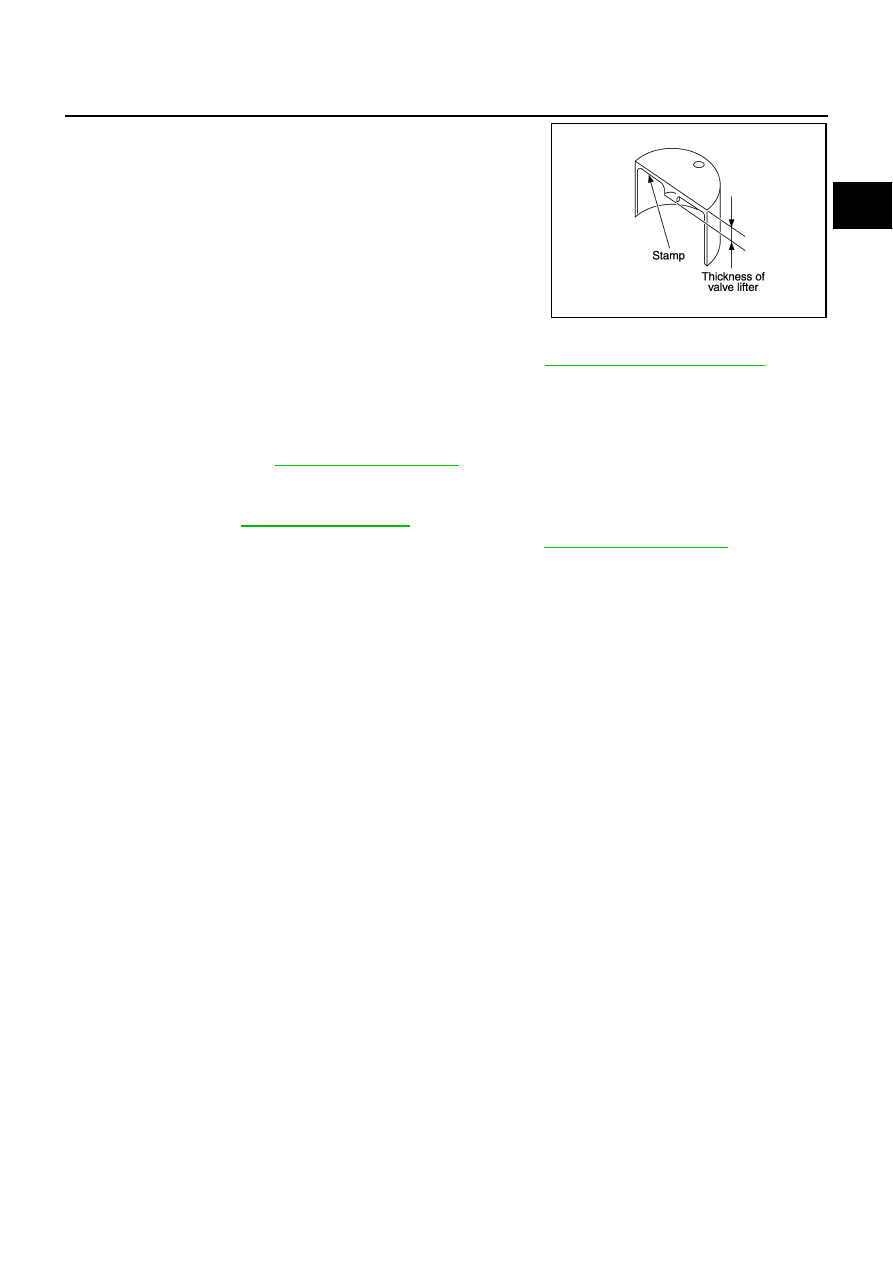

Thickness of new valve lifter can be identified by stamp marks

on the reverse side (inside the cylinder).

Stamp mark 788U or 788R indicates 7.88 mm (0.3102 in) in

thickness.

NOTE:

Two types of stamp marks are used for parallel setting and for

manufacturer identification.

●

Available thickness of valve lifter: 27 sizes with range 7.88 to 8.40 mm (0.3102 to 0.3307 in) in steps of

0.02 mm (0.0008 in) (when manufactured at factory). Refer to

EM-170, "Available Valve Lifter"

.

CAUTION:

Install identification letter at the end, “U” and “R”, at each of proper positions. (Be careful of

misinstallation between intake and exhaust)

6.

Install selected valve lifter.

7.

.

8.

Manually turn crankshaft pulley a few turns.

9.

Make sure that the valve clearances for cold engine are within the specifications by referring to the speci-

fied values. Refer to

10. Install all removal parts in the reverse order of removal. Refer to

11. Warm up the engine, and check for unusual noise and vibration.

KBIA0119E