Infiniti G35 (V35). Manual - part 322

DTC P0011, P0021 IVT CONTROL

EC-169

C

D

E

F

G

H

I

J

K

L

M

A

EC

5.

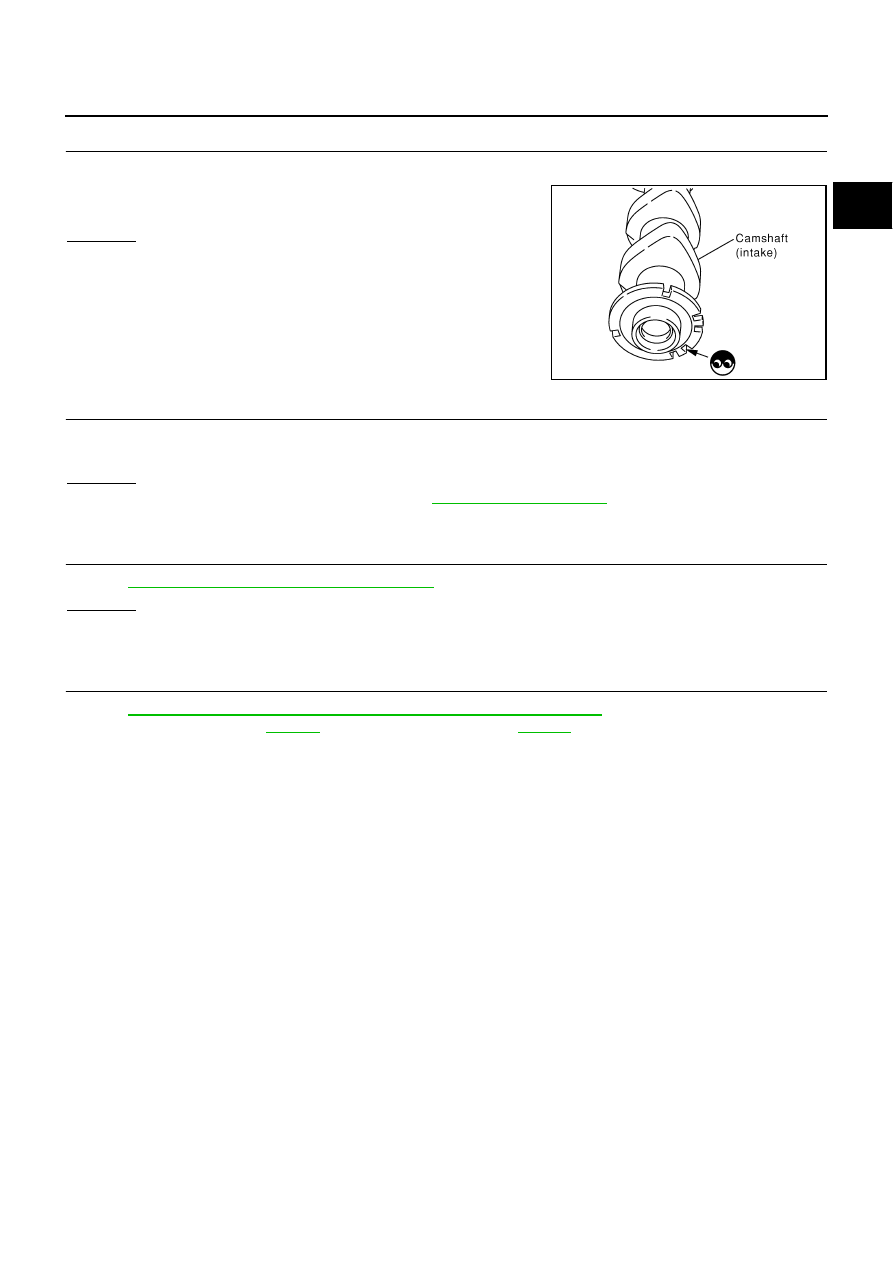

CHECK CAMSHAFT (INT)

Check the following.

●

Accumulation of debris to the signal plate of camshaft rear end

●

Chipping signal plate of camshaft rear end

OK or NG

OK

>> GO TO 6.

NG

>> Remove debris and clean the signal plate of camshaft

rear end or replace camshaft.

6.

CHECK TIMING CHAIN INSTALLATION

Check service records for any recent repairs that may cause timing chain misaligned.

Are there any service records that may cause timing chain misaligned?

Yes or No

Yes

>> Check timing chain installation. Refer to

.

No

>> GO TO 7.

7.

CHECK LUBRICATION CIRCUIT

Refer to

EM-102, "INSPECTION AFTER REMOVAL"

.

OK or NG

OK

>> GO TO 8.

NG

>> Clean lubrication line.

8.

CHECK INTERMITTENT INCIDENT

Refer to

EC-151, "TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT"

for CKP sensor (POS) and

>> INSPECTION END

SEC905C