Infiniti G35 (V35). Manual - part 233

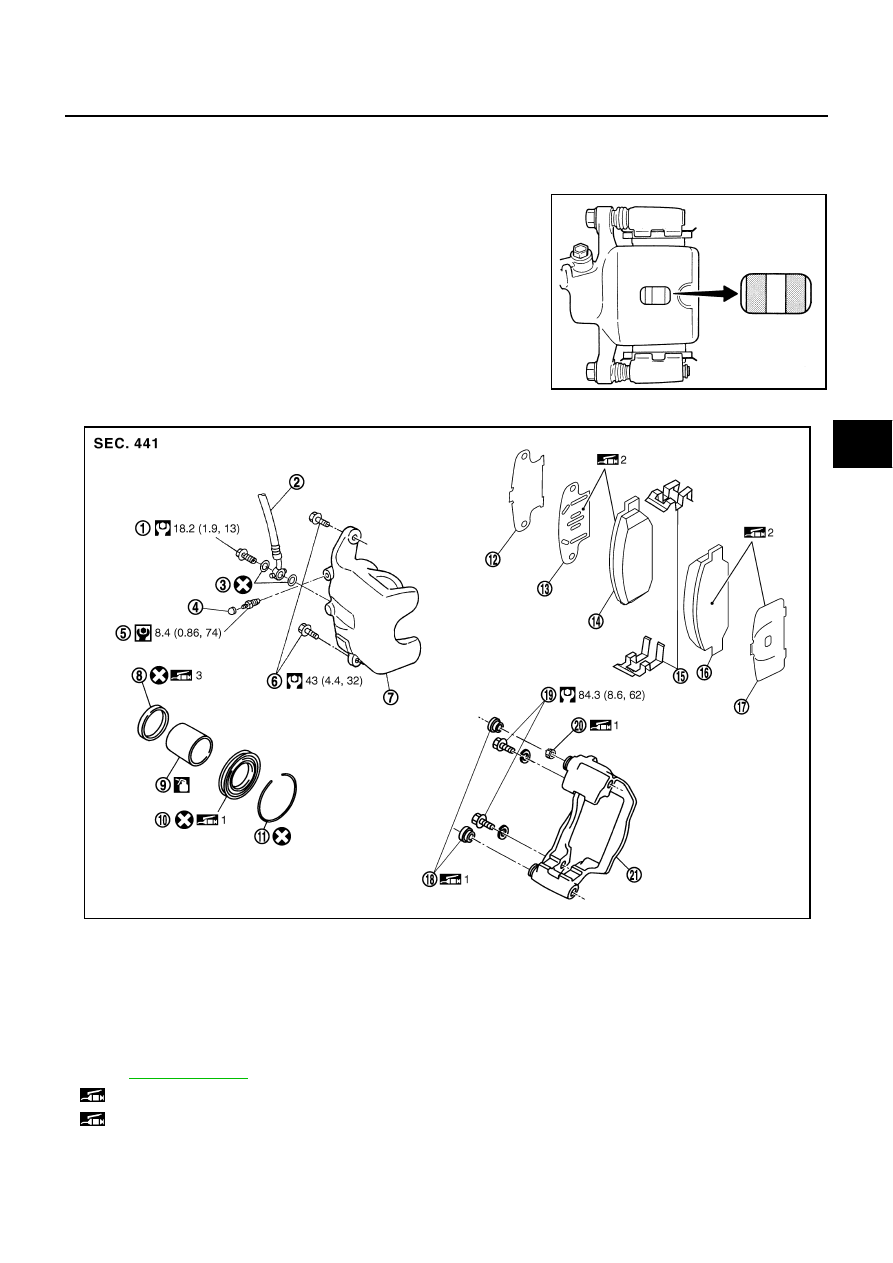

REAR DISC BRAKE

BR-27

C

D

E

G

H

I

J

K

L

M

A

B

BR

REAR DISC BRAKE

PFP:44000

On-Vehicle Inspection

NFS000K0

PAD WEAR INSPECTION

●

Inspect the thickness from an inspection hole on cylinder body.

Use a scale for inspection if necessary.

Components

NFS000K1

Standard thickness

: 8.5 mm (0.335 in)

Repair limit thickness

: 2.0 mm (0.079 in)

BRA0010D

1.

Union bolt

2.

Brake hose

3.

Copper washer

4.

Cap

5.

Bleed valve

6.

Sliding pin bolt

7.

Cylinder body

8.

Piston seal

9.

Piston

10.

Piston boot

11.

Retaining ring

12.

Inner shim cover

13.

Inner shim

14. Inner pad

15.

Pad retainer

16.

Outer pad

17. Outer shim

18.

Slide pin boot

19.

Torque member mounting bolt

20. Bushing

21.

Torque member

Refer to

and the followings for the symbols in the figure.

1: Apply rubber grease.

2: Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease.

PFIA0686E