Infiniti FX35 / FX45. Manual - part 910

SC-28

< SERVICE INFORMATION >

CHARGING SYSTEM

• Make sure that alternator pulley nut is tight.

INSTALLATION

Installation is the reverse order of removal.

• Install alternator, and check tension of belt. Refer to

CAUTION:

Be sure to tighten “B” terminal nut carefully.

Disassembly and Assembly

INFOID:0000000001328259

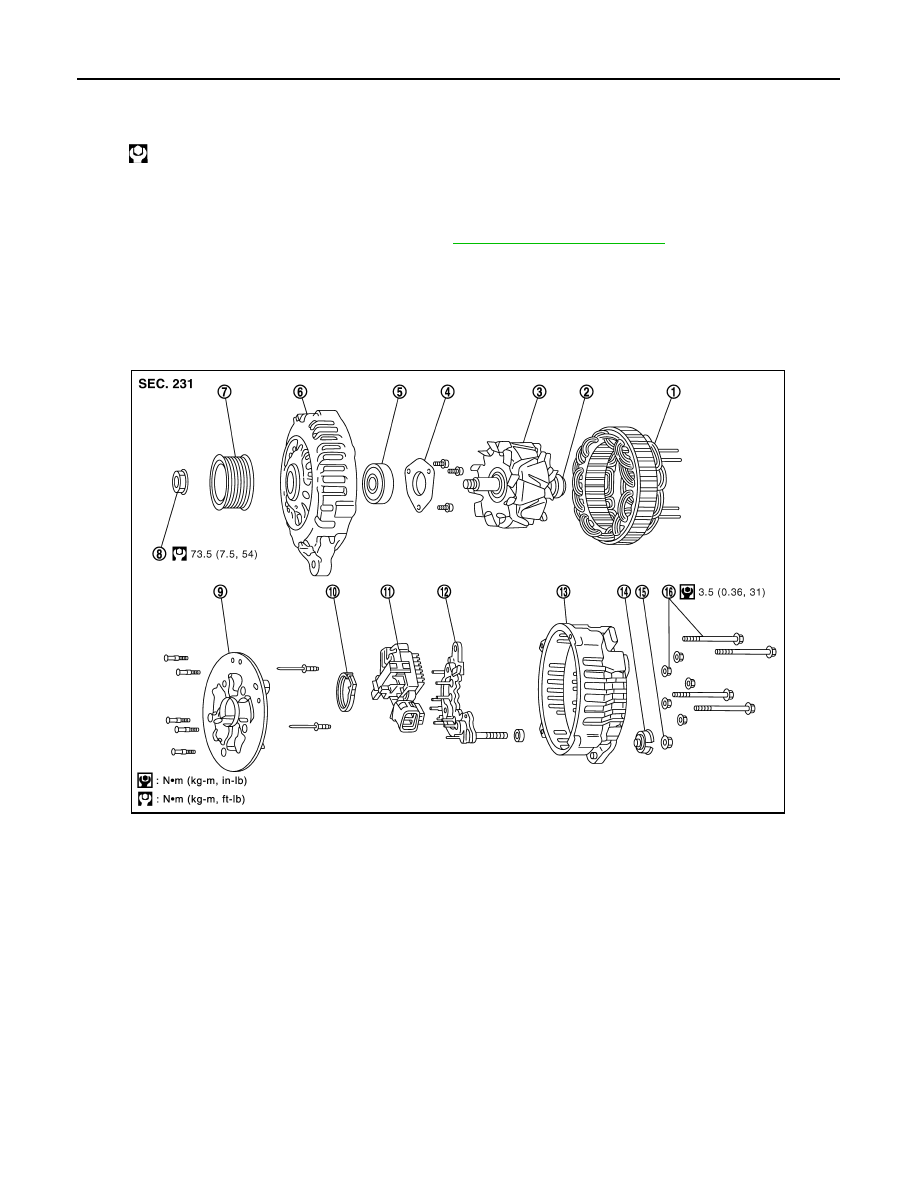

VK45DE ENGINE MODELS (LR1110-716B)

VQ35DE ENGINE MODELS (A3TG0191)

Alternator pulley nut:

: 118 N·m (12.0 kg-m, 87 ft-lb)

1.

Stator assembly

2.

Slip ring

3.

Rotor assembly

4.

Retainer

5.

Front bearing

6.

Front bracket assembly

7.

Pulley

8.

Pulley nut

9.

Fun guide

10.

Double labyrinth seal

11.

IC voltage regulator assembly

12. Diode assembly

13.

Rear bracket assembly

14. Bush

15. B terminal nut

16.

Through-bolt and nut

PKID0691E