Infiniti FX35 / FX45. Manual - part 646

CYLINDER HEAD

EM-101

< SERVICE INFORMATION >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

• If the engine speed is out of the specified range, check battery liquid for proper gravity. Check the

engine speed again with normal battery gravity.

• If compression pressure is below minimum value, check valve clearances and parts associated with

combustion chamber (valve, valve seat, piston, piston ring, cylinder bore, cylinder head, cylinder head

gasket). After the checking, measure compression pressure again.

• If some cylinder has low compression pressure, pour small amount of engine oil into the spark plug hole

of the cylinder to re-check it for compression.

- If the added engine oil improves the compression, piston rings may be worn out or damaged. Check pis-

ton rings and replace if necessary.

- If the compression pressure remains at low level despite the addition of engine oil, valves may be mal-

functioning. Check valves for damage. Replace valve or valve seat accordingly.

• If two adjacent cylinders have respectively low compression pressure and their compression remains

low even after the addition of engine oil, cylinder head gaskets are leaking. In such a case, replace cyl-

inder head gaskets.

9.

After inspection is completed, install removed parts.

10. Start the engine, and make sure that the engine runs smoothly.

11. Perform trouble diagnosis. If DTC appears, erase it. Refer to

EC-89, "Trouble Diagnosis Introduction"

Component

INFOID:0000000001325738

Removal and Installation

INFOID:0000000001325739

REMOVAL

1.

Remove camshaft. Refer to

.

NOTE:

It is also possible to perform the following steps 2 and 3 just before removing camshaft.

2.

Temporarily fit front suspension member to support engine. Refer to

FSU-16, "Removal and Installation"

.

CAUTION:

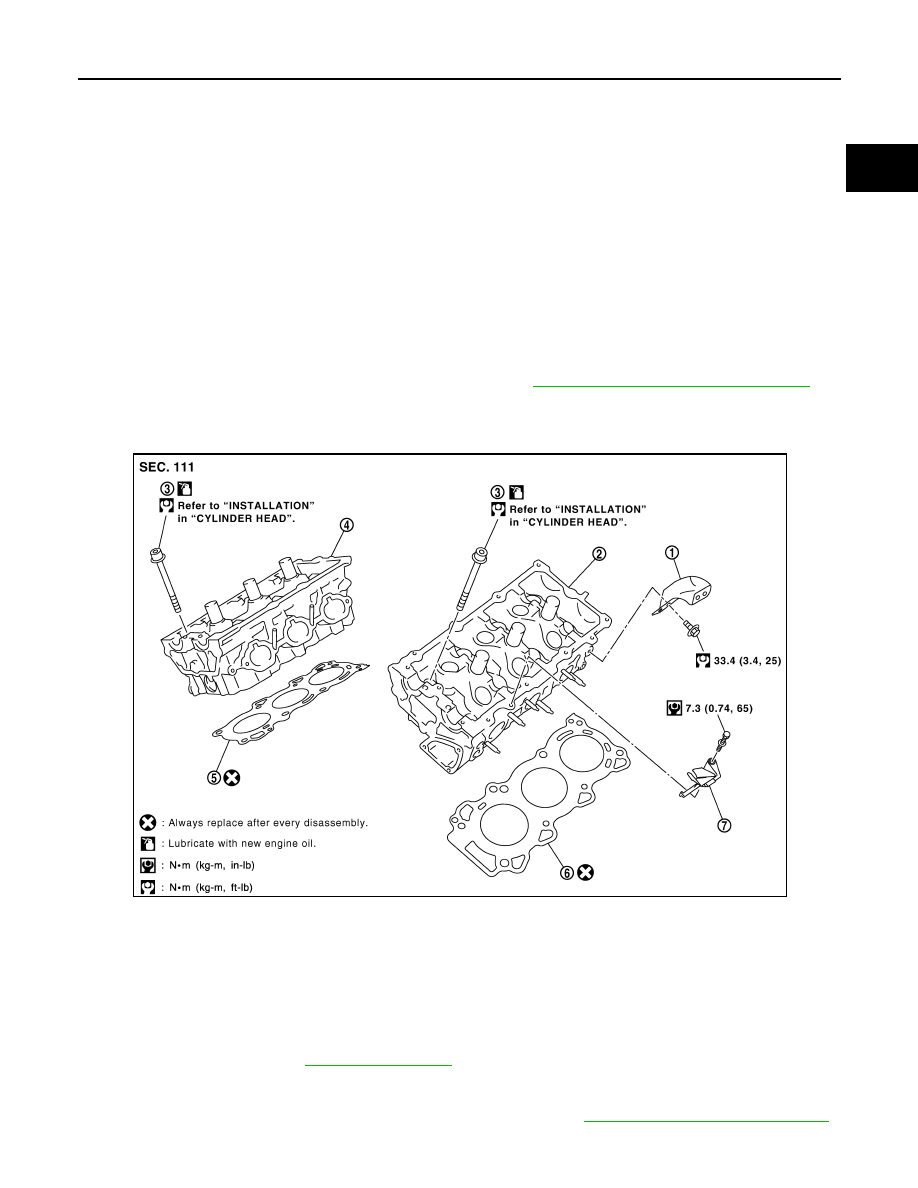

1.

Engine rear lower slinger

2.

Cylinder head (left bank)

3.

Cylinder head bolt

4.

Cylinder head (right bank)

5.

Cylinder head gasket (right bank)

6.

Cylinder head gasket (left bank)

7.

Oil level gauge guide

SBIA0581E