Infiniti FX35 / FX45. Manual - part 460

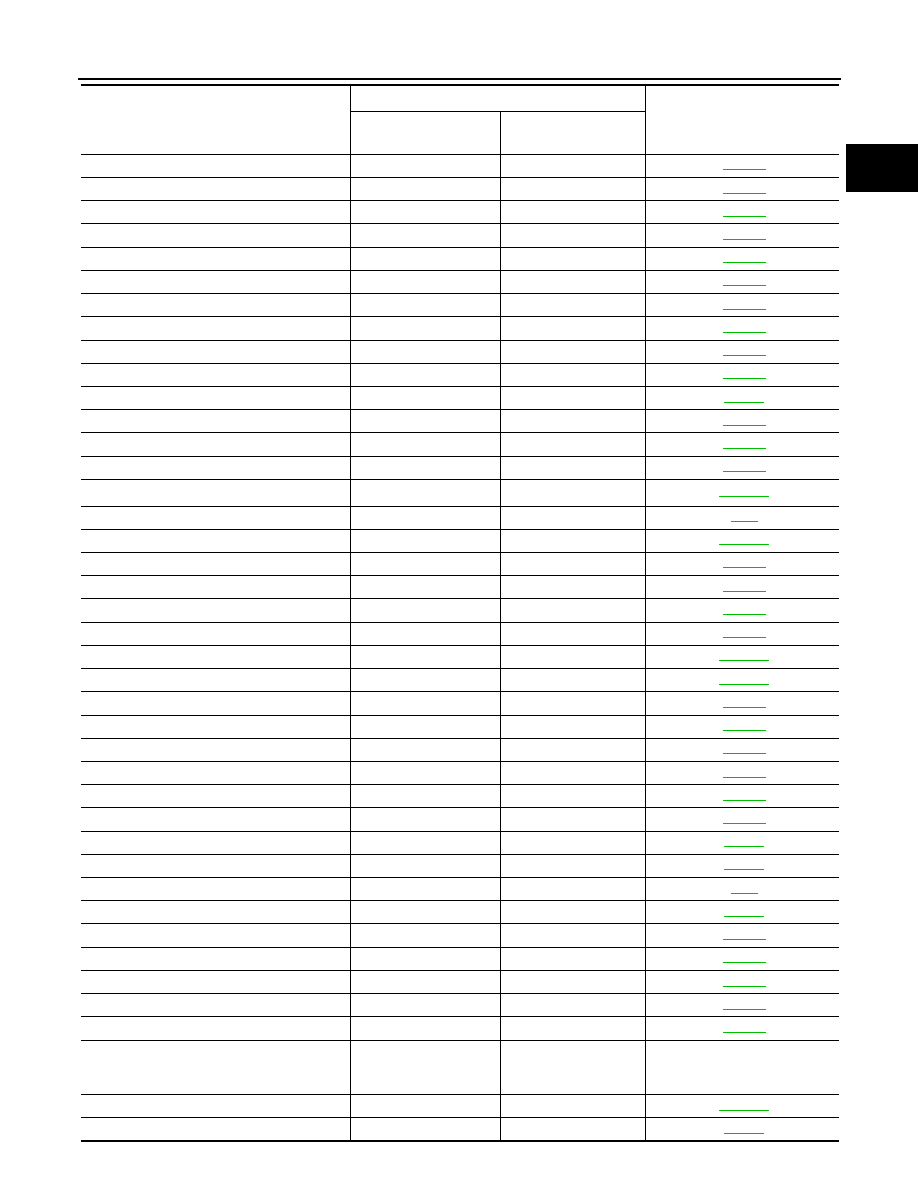

INDEX FOR DTC

EC-601

< SERVICE INFORMATION >

[VK45DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

HO2S2 (B1)

P0137

0137

HO2S2 (B1)

P0138

0138

HO2S2 (B1)

P0139

0139

HO2S2 (B2)

P0157

0157

HO2S2 (B2)

P0158

0158

HO2S2 (B2)

P0159

0159

HO2S2 HTR (B1)

P0037

0037

HO2S2 HTR (B1)

P0038

0038

HO2S2 HTR (B2)

P0057

0057

HO2S2 HTR (B2)

P0058

0058

I/C SOLENOID/CIRC

P1752

1752

IAT SEN/CIRCUIT-B1

P0112

0112

IAT SEN/CIRCUIT-B1

P0113

0113

IAT SENSOR-B1

P0127

0127

ICC COMMAND VALUE*

6

P1568

1568

ID DISCORD, IMM-ECM

P1611

1611

IN PULY SPEED

P1715

1715

INT/V TIM CONT-B1

P0011

0011

INT/V TIM CONT-B2

P0021

0021

INT/V TIM V/CIR-B1

P0075

0075

INT/V TIM V/CIR-B2

P0081

0081

INTK TIM S/CIRC-B1

P1140

1140

INTK TIM S/CIRC-B2

P1145

1145

ISC SYSTEM

P0506

0506

ISC SYSTEM

P0507

0507

KNOCK SEN/CIRC-B1

P0327

0327

KNOCK SEN/CIRC-B1

P0328

0328

KNOCK SEN/CIRC-B2

P0332

0332

KNOCK SEN/CIRC-B2

P0333

0333

L/PRESS SOL/CIRC

P0745

0745

LC/B SOLENOID FNCT

P1774

1774

LC/B SOLENOID/CIRC

P1610

1610

LOCK MODE

P1772

1772

MAF SEN/CIRCUIT-B1

P0101

0101

MAF SEN/CIRCUIT-B1

P0102

0102

MAF SEN/CIRCUIT-B1

P0103

0103

MULTI CYL MISFIRE

P0300

0300

NATS MALFUNCTION

P1610 - P1615

1610 - 1615

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.

P0000

0000

—

P-N POS SW/CIRCUIT

P0850

0850

PNP SW/CIRC

P0705

0705

Items

(CONSULT-III screen terms)

DTC*

1

Reference page

CONSULT-III

GST*

2

ECM*

3