Hyundai: Engine D4FA. Manual - part 113

DIESEL CONTROL SYSTEM

FLA -323

DTC DESCRIPTION

E2A1B928

P0611 is set when the problems of more than 2 injector circuits are detected thus, it is difficult to find abnormal injector.

Check "Circuit Inspection" of all injectors

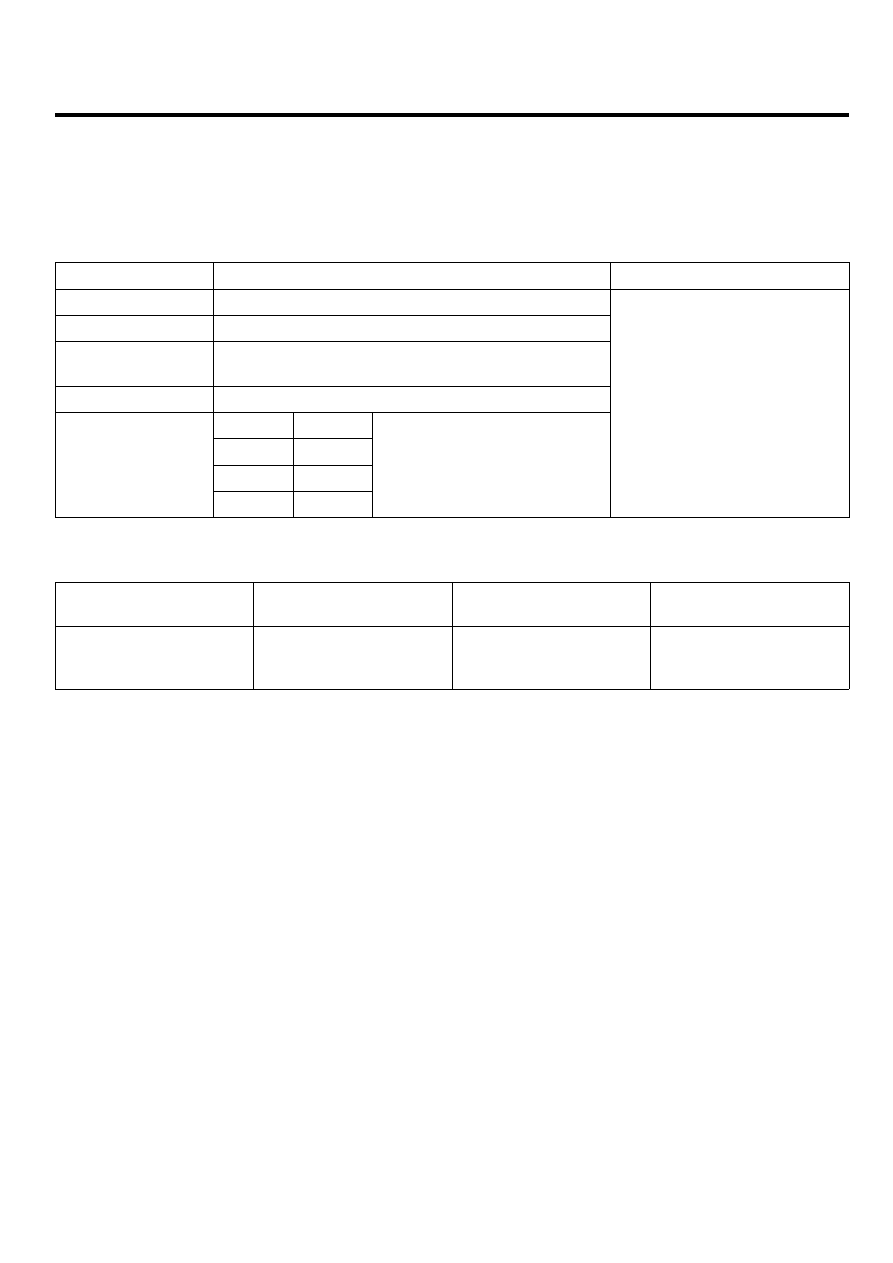

DTC DETECTING CONDITION

EB903688

Item

Detecting Condition

Possible Cause

DTC Strategy

• Current monitoring

Enable Conditions

• IG KEY "ON"

ThresholdValue

• Cylinder recognition is impossible due to the

failure more than 2 injectors.

DiagnosticTime

• Immediately

Fuel Cut

YES

EGR Off

NO

Fuel Limit

NO

Fail Safe

MIL

YES

• Short in Injector circuit

• Injector component

SPECIFICATION

E43C5A79

Injector Component

Resistance

Injector Operating Voltage

Injector Operating

Current

Injector Control Type

0.255Ω ±0.04 (20℃).

80V

Peak current : 18±1A

Hold in current : 12±1A

Recharging current : 7A

Current control