Hyundai Getz: Body Repair Manual - part 24

101

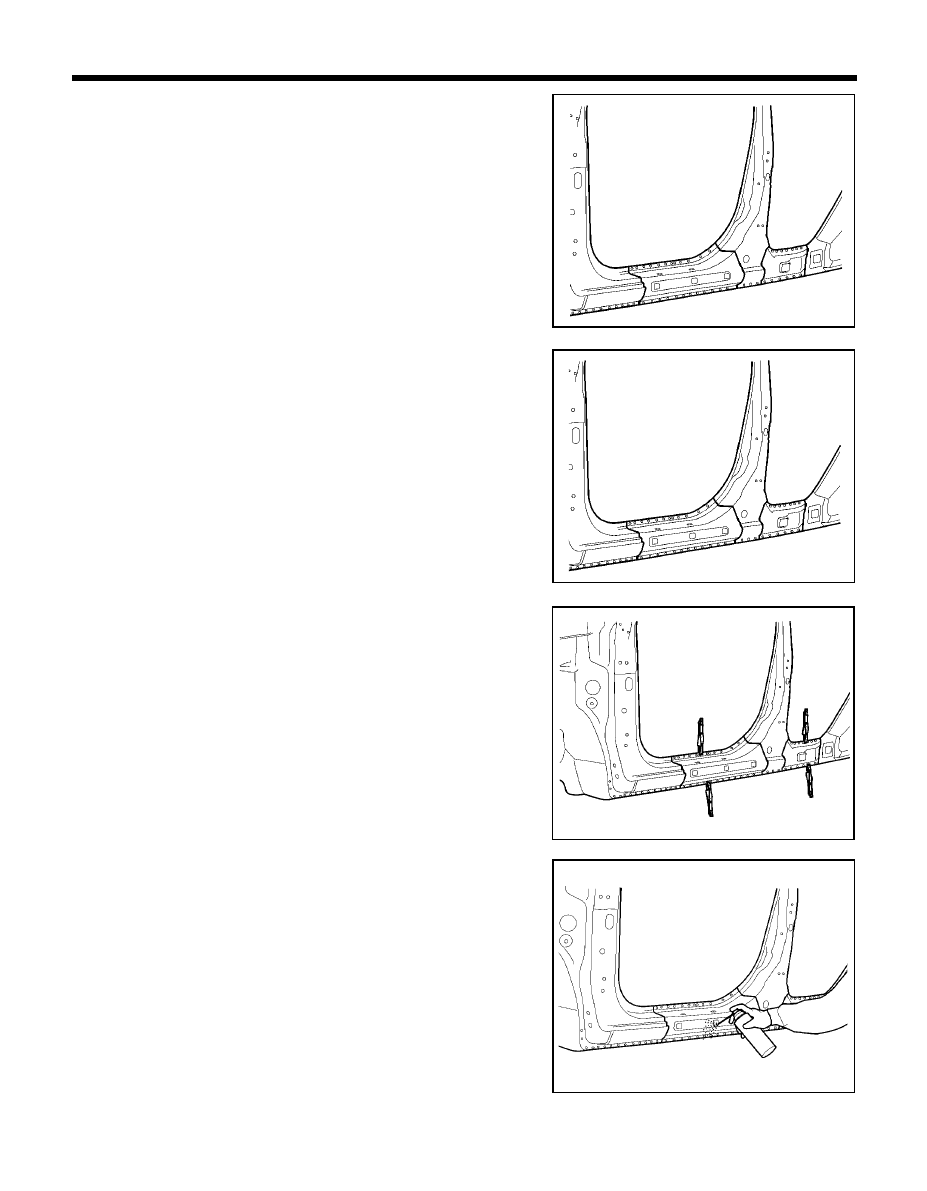

BODY PANEL REPAIR PROCEDURE - Side sill (Assembly)

3.

Cut the side sill outer panel along cutlines. Be careful not to cut

mating flanges.

4.

Drill out all spotwelds, attaching the side sill outer panel to side

outer reinforcement.

5.

Remove the side sill outer panel.

6.

Determine if the side outer reinforcement is damaged and needs

to be replaced, measure cutline on reinforcement as shown in the

illustration.

7.

Cut side sill outer reinforcement along the cutline.

8.

Drill out spotwelds attaching the side outer reinforcement to the

body and remove side outer reinforcement.

9.

Prepare all surfaces to be welded.

INSTALLATION

1.

Transcribe cutline dimension to side sill outer panel, adding

30mm overlap to rear end and cut to length.

2.

Drill 8mm holes in overlap area on rear end and along front flange.

3.

Fit and clamp the side sill outer reinforcement in place.

4.

MIG plug weld all holes and MIG butt weld seams.

5.

Before welding the side sill outer panel, apply the two-part epoxy

primer and anti-corrosion agent to the welded parts.

NOTE

The reinforcement will be stronger if the weld traces are not

ground.

PRO-1020

PRO-1020

PRO-1030

PRO-1040