Hummer H2. Manual - part 940

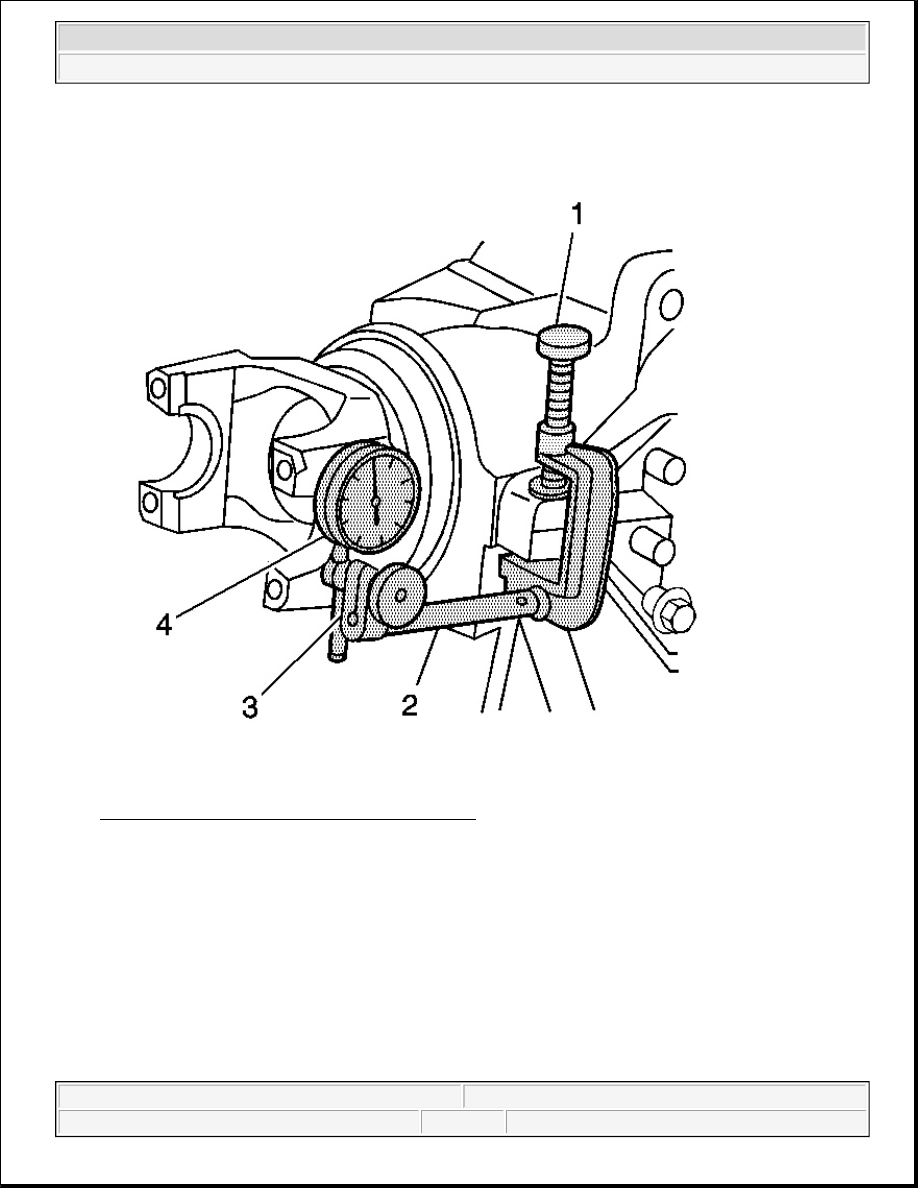

Fig. 126: Installing J 8001-1, J 8001-2 & J 8001-3

Courtesy of GENERAL MOTORS CORP.

2. Install the J 8001-1 (1, 2), the J 8001-2 (3), and the J 8001-3 (4) as shown.

Ensure that the button contacts the outer edge of the pinion yoke and that the plunger is at a right angle to

the pinion yoke.

3. Move the pinion yoke back and forth through the pinion yoke's free play while not allowing the ring gear

to move.

4. Record the dial indicator reading.

5. To determine the actual backlash, divide the dial indicator reading by 2.

2004 Hummer H2

2004 DRIVELINE/AXLE Front Drive Axle - Hummer H2