Hummer H2. Manual - part 260

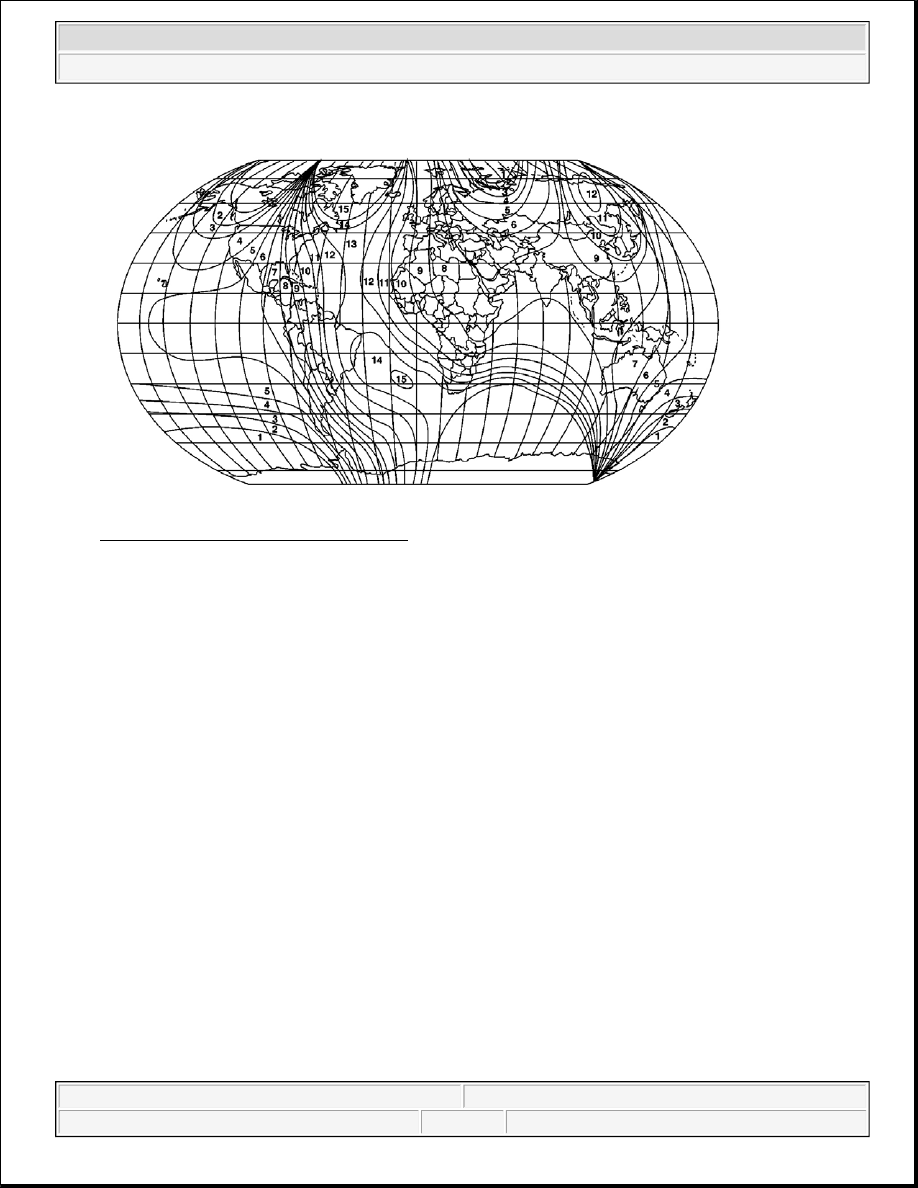

Fig. 45: World Magnetic Variation Map

Courtesy of GENERAL MOTORS CORP.

1. Locate your current geographic location on the World Magnetic Variation Map.

2. Turn ON the ignition, with the engine OFF.

3. Press and hold the switch for the compass, which may be depicted as COMP, COMPASS, or on/off

(w/UE1) depending on the type of mirror on the vehicle, until a zone number appears on the compass

display.

4. Depress the switch for the compass to select the desired zone number.

5. Wait 5 seconds. The display will return to a compass heading. The variance procedure is now complete.

6. Calibrate the compass. Refer to Compass Calibration mentioned above.

REAR WINDOW DEFOGGER DESCRIPTION AND OPERATION

Rear Window Defogger System Components

The rear window defogger system consist of the following components:

z

HVAC control module

z

Body control module (BCM)

z

DEFOG relay

z

Rear window defogger grid

Rear Window Defogger Operation

2004 Hummer H2

2004 ACCESSORIES & EQUIPMENT Stationary Windows - Hummer H2