Content .. 1261 1262 1263 1264 ..

Hummer H2. Manual - part 1263

GENERAL ELECTRICAL DIAGNOSIS PROCEDURES

Basic Knowledge Required

Without a basic knowledge of electricity, it will be difficult to use the diagnostic procedures contained in the

service manual. You should understand the basic theory of electricity, and know the meaning of voltage (volts),

current (amps), and resistance (ohms). You should also be able to read and understand a wiring diagram, as well

as understand what happens in a circuit with an open or a shorted wire.

CHECKING AFTERMARKET ACCESSORIES

Do not connect aftermarket accessories into the following circuits:

z

SIR circuits, all such circuits are indicated on circuit diagrams with the SIR symbol.

z

OBD II circuits, all such circuits are indicated on circuit diagrams with the OBD II symbol.

Always check for aftermarket accessories (non-OEM) as the first step in diagnosing electrical problems. If the

vehicle is so equipped, disconnect the system to verify that these add-on accessories are not the cause of the

problems.

Possible causes of vehicle problems related to aftermarket accessories include:

z

Power feeds connected to points other than the battery

z

Antenna location

z

Transceiver wiring located too close to vehicle electronic modules or wiring

z

Poor shielding or poor connectors on antenna feed line

z

Check for recent service bulletins detailing installation guidelines for aftermarket accessories.

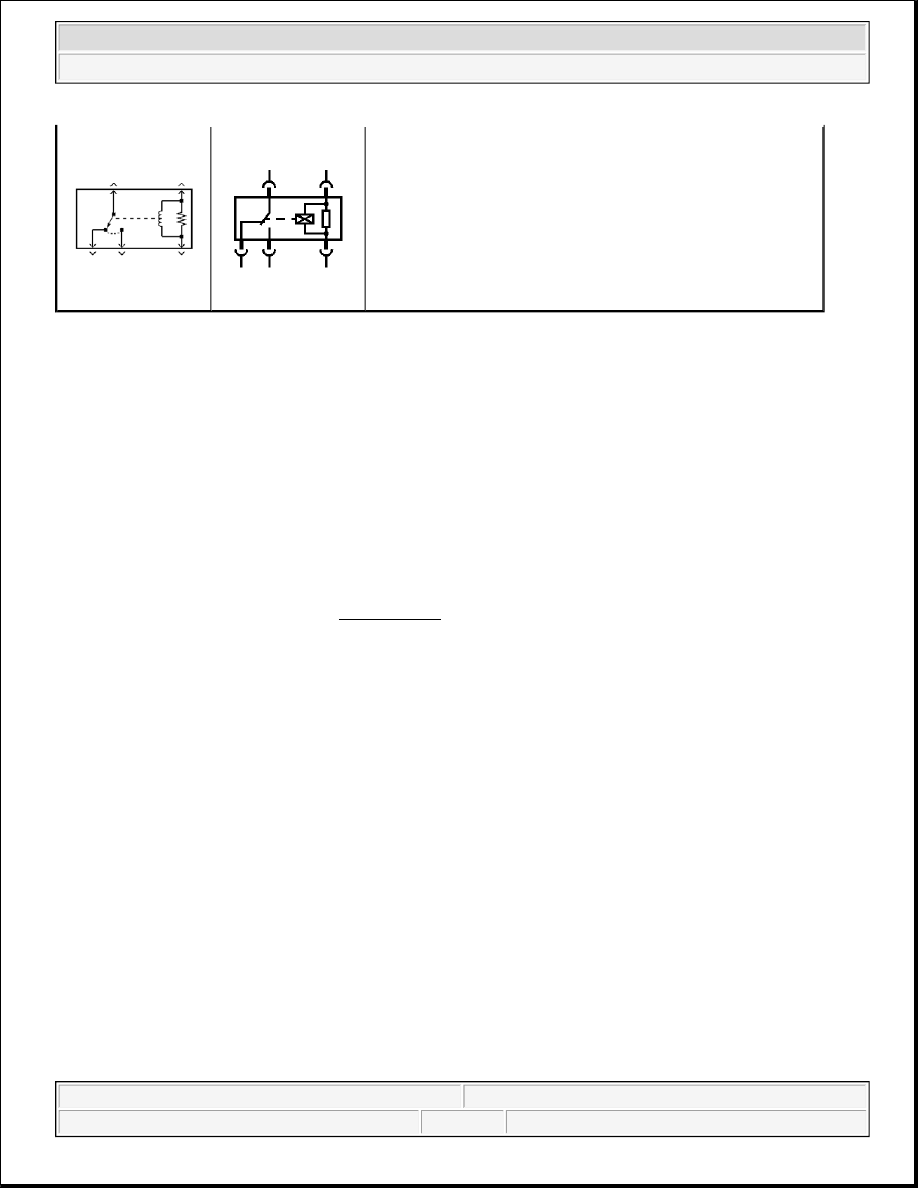

Single Pole/Throw Relay - Normally Closed

CAUTION: Refer to SIR Caution in Cautions and Notices.

NOTE:

Refer to OBD II Symbol Description Notice in Cautions and Notices.

2004 Hummer H2

2004 ACCESSORIES & EQUIPMENT Wiring Systems - Hummer H2