Hummer H2. Manual - part 83

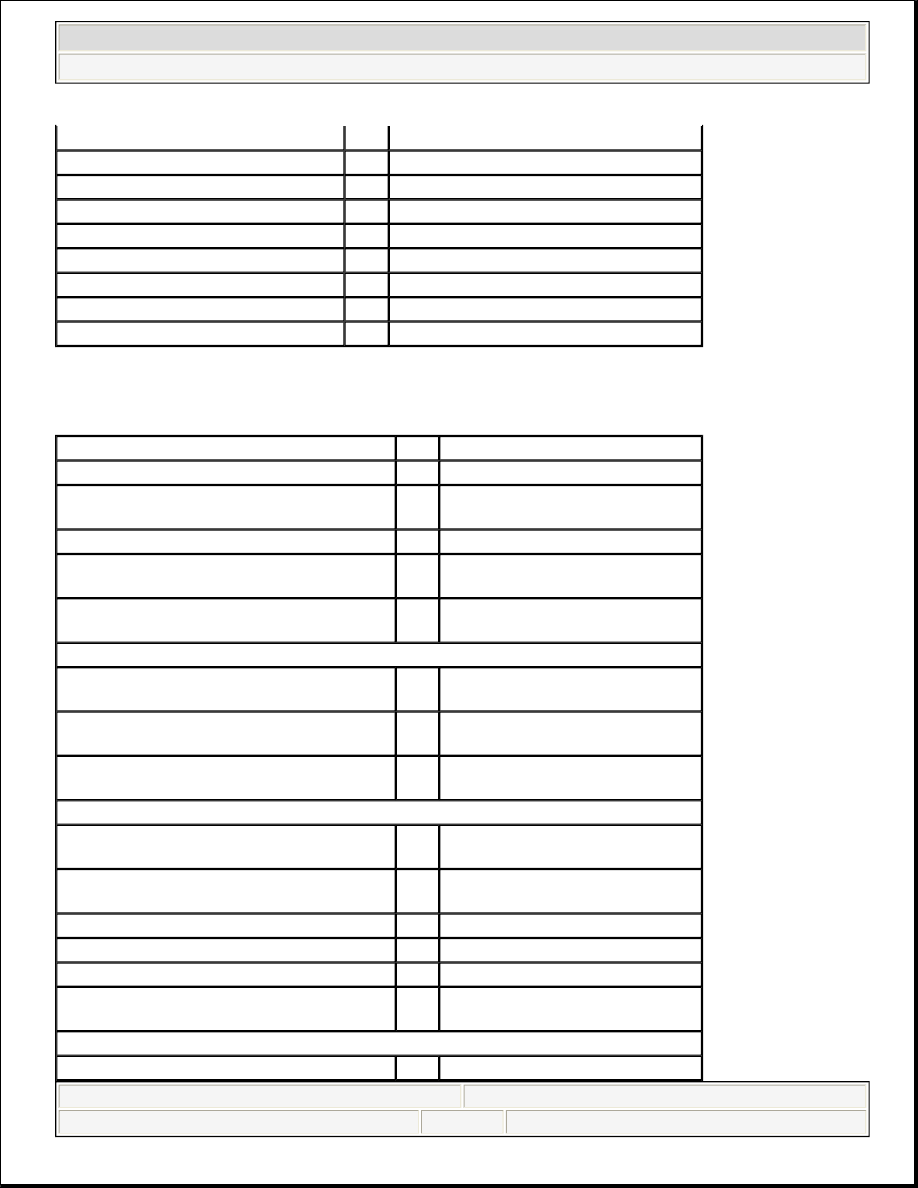

VACUUM BOOSTERS

Vacuum Boosters

Alignment incorrect

B

Require repair or replacement.

Bent

B

Require replacement.

Contaminated, affecting performance

A

Require repair. Identify and correct cause.

Cracked

B

Require replacement.

Loose

A

Require replacement of worn parts.

Missing

C

Require replacement.

Number of teeth incorrect

B

Require replacement.

Teeth broken

A

Require replacement.

Teeth damaged, affecting performance

A

Require replacement.

Condition

Code

Procedure

Applies too much assist (oversensitive)

A

Require replacement.

Attaching hardware broken

A

Require repair or replacement of

hardware.

Attaching hardware missing

C

Require replacement of hardware.

Attaching hardware not functioning

A

Require repair or replacement of

hardware.

Auxiliary vacuum pump inoperative

A

Require repair or replacement. See

note below.

NOTE: Inoperative includes intermittent operation or out of OEM specification.

Check valve grommet deteriorated, affecting

performance

A

Require replacement of grommet.

Check valve grommet deteriorated, not

affecting performance

1

Suggest replacement of grommet.

Check valve inoperative

A

Require repair or replacement. See

note below.

NOTE: Inoperative includes intermittent operation.

Check valve leaking

A

Require replacement of check

valve.

Check valve missing

C

Require replacement of check

valve.

Check valve noisy

2

Suggest replacement.

Connector broken

A

Require repair or replacement.

Connector (Weatherpack type) leaking

A

Require repair or replacement.

Connector melted

A

Require replacement. See note

below.

NOTE: Determine cause and correct prior to replacement of part.

Connector missing

C

Require replacement.

1998 Chevrolet Pickup C1500

Uniform Inspection and Communication Standards BRAKE SYSTEMS