Hummer H2. Manual - part 32

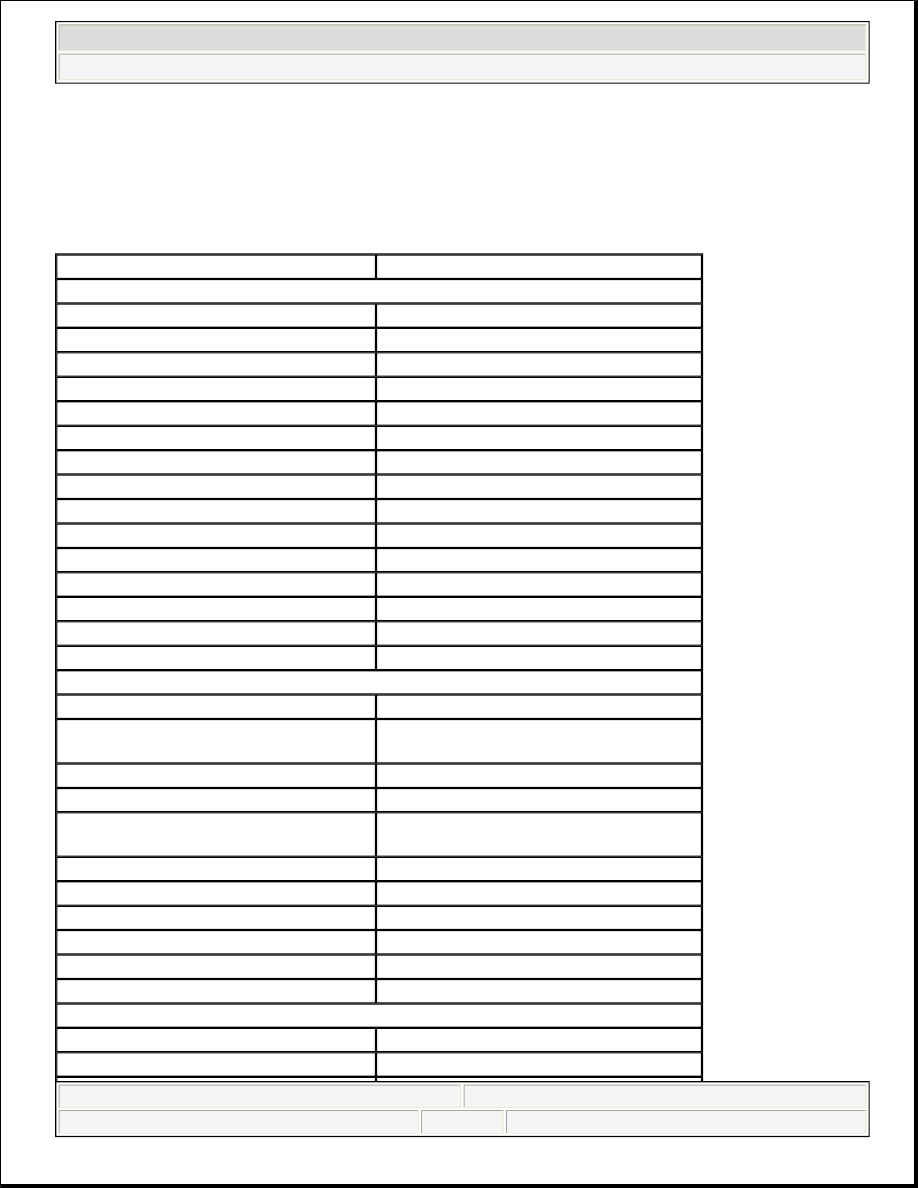

BASIC CLUTCH TROUBLE SHOOTING CHART

unique situation or individual vehicle configuration. The purpose of this Trouble

Shooting information is to provide a list of common causes to problem

symptoms. For model-specific Trouble Shooting, refer to SUBJECT,

DIAGNOSTIC, or TESTING articles available in the section(s) you are accessing.

CONDITION & POSSIBLE CAUSE

CORRECTION

Chattering or Grabbing

Incorrect clutch adjustment

Adjust clutch

Oil, grease or glaze on facings

Disassemble and clean or replace

Loose "U" joint flange

See DRIVE AXLES article

Worn input shaft spline

Replace input shaft

Binding pressure plate

Replace pressure plate

Binding release lever

See CLUTCH article

Binding clutch disc hub

Replace clutch disc

Unequal pressure plate contact

Replace worn/misaligned components

Loose/bent clutch disc

Replace clutch disc

Incorrect transmission alignment

Realign transmission

Worn pressure plate, disc or flywheel

Replace damaged components

Broken or weak pressure springs

Replace pressure plate

Sticking clutch pedal

Lubricate clutch pedal & linkage

Incorrect clutch disc facing

Replace clutch disc

Engine loose in chassis

Tighten all mounting bolts

Failure to Release

Oil or grease on clutch facings

Clean or replace clutch clutch disc

Incorrect release lever or pedal

adjustment

See CLUTCH article

Worn or broken clutch facings

Replace clutch disc

Bent clutch disc or pressure plate

Replace damaged components

Clutch disc hub binding on input shaft

Clean or replace clutch disc and/or input

shaft

Binding pilot bearing

Replace pilot bearing

Sticking release bearing sleeve

Replace release bearing and/or sleeve

Binding clutch cable

See CLUTCH article

Defective clutch master

Replace master cylinder

Defective clutch slave

Replace slave cylinder

Air in hydraulic system

Bleed hydraulic system

Rattling

Weak or broken release lever spring

Replace spring and check alignment

Damaged pressure plate

Replace pressure plate

1998 Chevrolet Pickup C1500

GENERAL INFORMATION Trouble Shooting - Basic Procedures