Hummer H1 (2002+). Manual - part 276

_____________________________________________________

PCM/Tech 1 Scan Tool 37

®

05745159

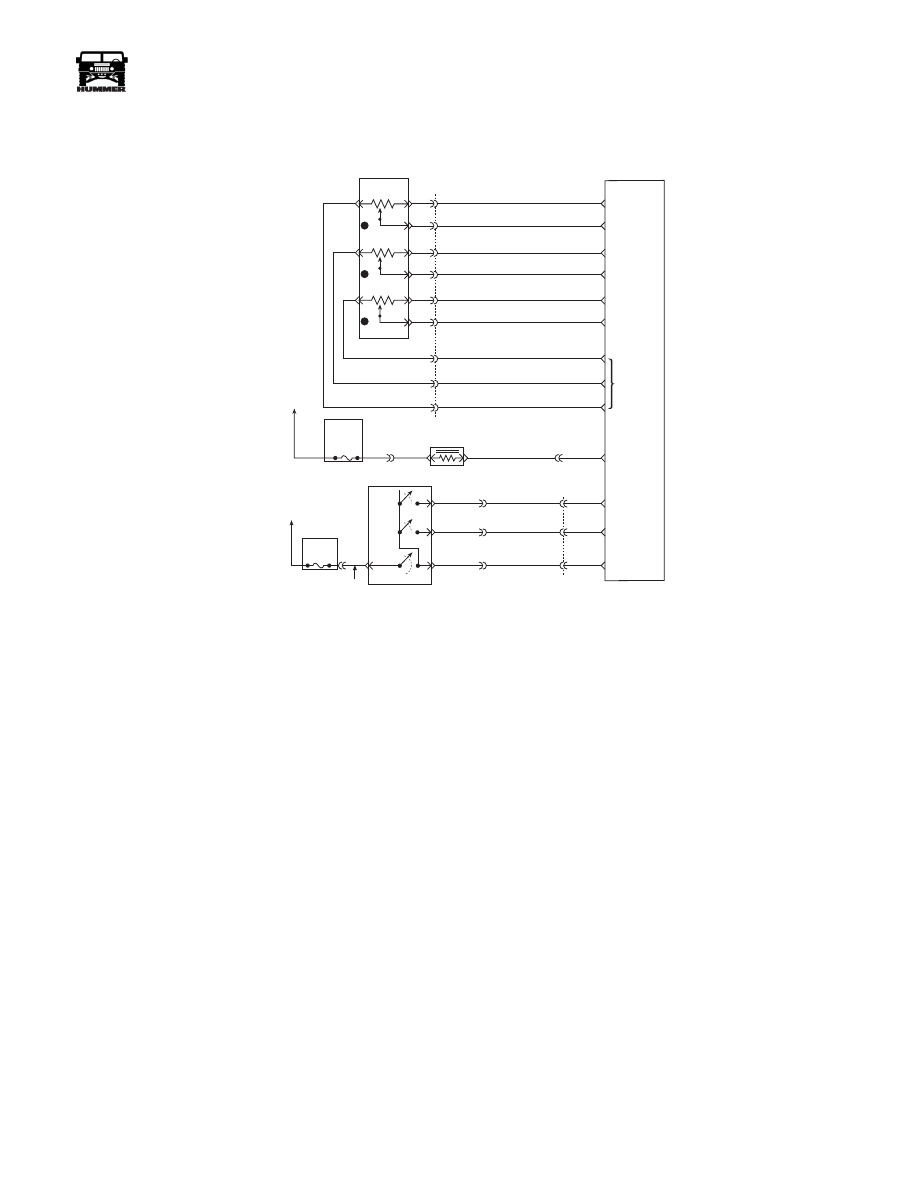

DTC P0123 Accelerator Pedal Position (APP)

Sensor 1 Circuit High Voltage

Circuit Description

The Accelerator Pedal Position (APP) module provides a volt-

age signal that changes relative to accelerator position. There

are three sensors located within the APP module that are scaled

differently. This is a type C DTC.

Conditions for Setting the DTC

• Voltage is greater than 4.75 volts on APP 1 sensor.

• Conditions met for 2 seconds.

Action Taken When the DTC Sets

• The input from APP 1 sensor is ignored.

• A current and history DTC will set but it will not turn on

the “Check Throttle” lamp. The throttle will operate

normally as long as there is only one sensor malfunc-

tioning. If two different APP sensors have a malfunc-

tion, the “Check Throttle” lamp will light and the PCM

will limit power. If three APP sensors have a malfunc-

tion present, the “Service Throttle Soon” lamp will light

and the PCM will only allow the engine to operate at

idle.

Conditions for Clearing the MIL/DTC

• A History DTC will clear when forty consecutive

warm-up cycles that the diagnostic does not fail (coolant

temperature has risen 5°C (40°F) from start up coolant

temperature and engine coolant temperature exceeds

71°C (160°F) that same ignition cycle).

• Use of a Scan Tool

Diagnostic Aids

A scan tool reads APP 1 position in volts. It should read about

.45 to .95 volt with throttle closed and ignition “ON” or at idle.

Voltage should increase at a steady rate as throttle is moved to-

ward Wide Open Throttle (WOT). Also, 90% pedal travel is

acceptable for correct APP operation. Scan APP 1 sensor while

depressing accelerator pedal with engine stopped and ignition

“ON”. Display should vary from about .74 volt when throttle is

closed to about 3.7 volts when throttle is held at Wide Open

Throttle (WOT) position. A P0123 will result if the ground cir-

cuit is open or the signal circuit is shorted to voltage. Refer to

Intermittents in Section 2.

Test Description

Number(s) below refer to the number(s) on the diagnostic ta-

ble.

2. This step determines if DTC P0123 is the result of a hard

failure or an intermittent condition.

3. This step checks the PCM and wiring.

FUSE 5C

10AMP

INTERIOR

FUSE 3A

10 AMP

EXTERIOR

ON/

OFF

SET

COAST

RESUME

ACCEL

HOT IN RUN

AND START

HOT IN RUN

AND START

A

29

42

37

C1

C29-A11

C29-B11

C27-D10

C28-D14

C28-C2

C27-D12

C27-D3

C27-D4

C27-D6

C29-B2

C29-B1

C27-C5

C29-A12

C5-D3

C5-A4

A

B

154 TN

151 GY

152 DB

153 LG

ON / OFF

SIGNAL

SET

COAST

SIGNAL

RESUME

ACCEL

SIGNAL

WASTEGATE

SOLENOID

CONTROL

5 VOLT

REFERENCE

APP 3

SIGNAL

GROUND

APP 1

SIGNAL

GROUND

GROUND

D

B

C

A

G

E

F

J

K

3

1

2

C1

22

20

14

15

60

32

53

17

44

720 TN

717 WH

723 YL

724 DG

725 GY

718 DB

719 BR

721 LB

722 PP

ACCELERATIOR

PEDAL POSITION

SENSOR

POWERTRAIN

CONTROL

MODULE

(PCM)

APP 2

SIGNAL

9-S12-055

B

C

D

295 BR

YL

GRN

RD