Hummer H1 (2002+). Manual - part 202

______________________________________________________

Electrical System 12-35

®

05745159

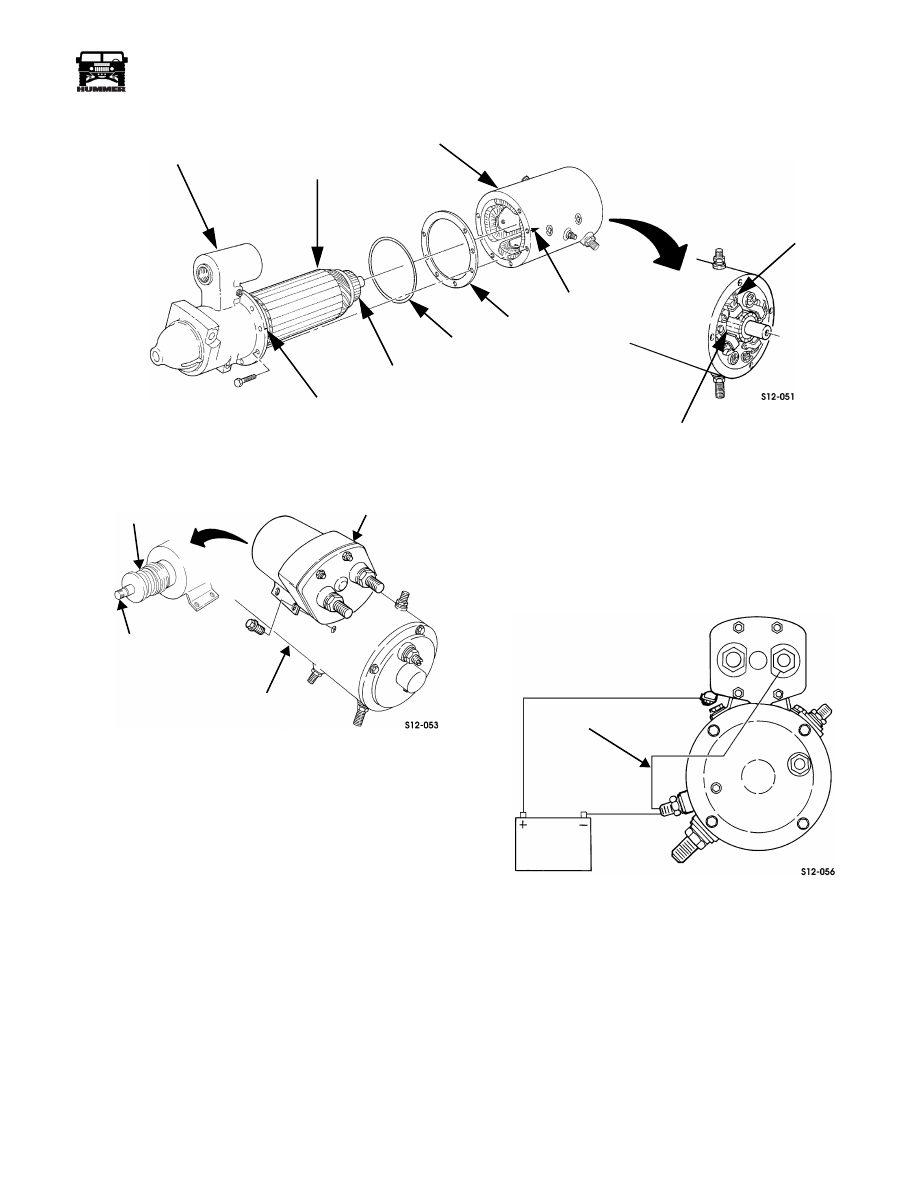

Figure 12-66: Assembling Frame, Armature, and Pinion Housing

Figure 12-67: Solenoid Boot Installation

Starter Pinion Clearance

Adjustment

1.

Connect battery and jumper to starter as shown

(Figure 12-68). Momentarily touch jumper to solenoid

frame to shift pinion into cranking position.

Figure 12-68: Battery and Jumper Connections

for Pinion Clearance Check

2.

Check clearance between pinion and snap ring with feeler

gauge (Figure 12-69).

3.

Disconnect battery.

4.

Pinion clearance should be 0.005-0.030 in. (0.127-0.762

mm). If adjustment is necessary, remove end plate and add

or remove thrust washer(s) (Figure 12-69).

PINION HOUSING

ARMATURE

FRAME

MARK

GASKET

O-RING

COMMUTATOR

COMMUTATOR

BRUSHES

SCRIBE

MARK

SCRIBE

SOLENOID

FRAME

BOOT (COAT

CORE SHAFT

WITH GREASE)

JUMPER WIRE

4-1-00