Hummer H1 (2002+). Manual - part 197

______________________________________________________

Electrical System 12-15

®

05745159

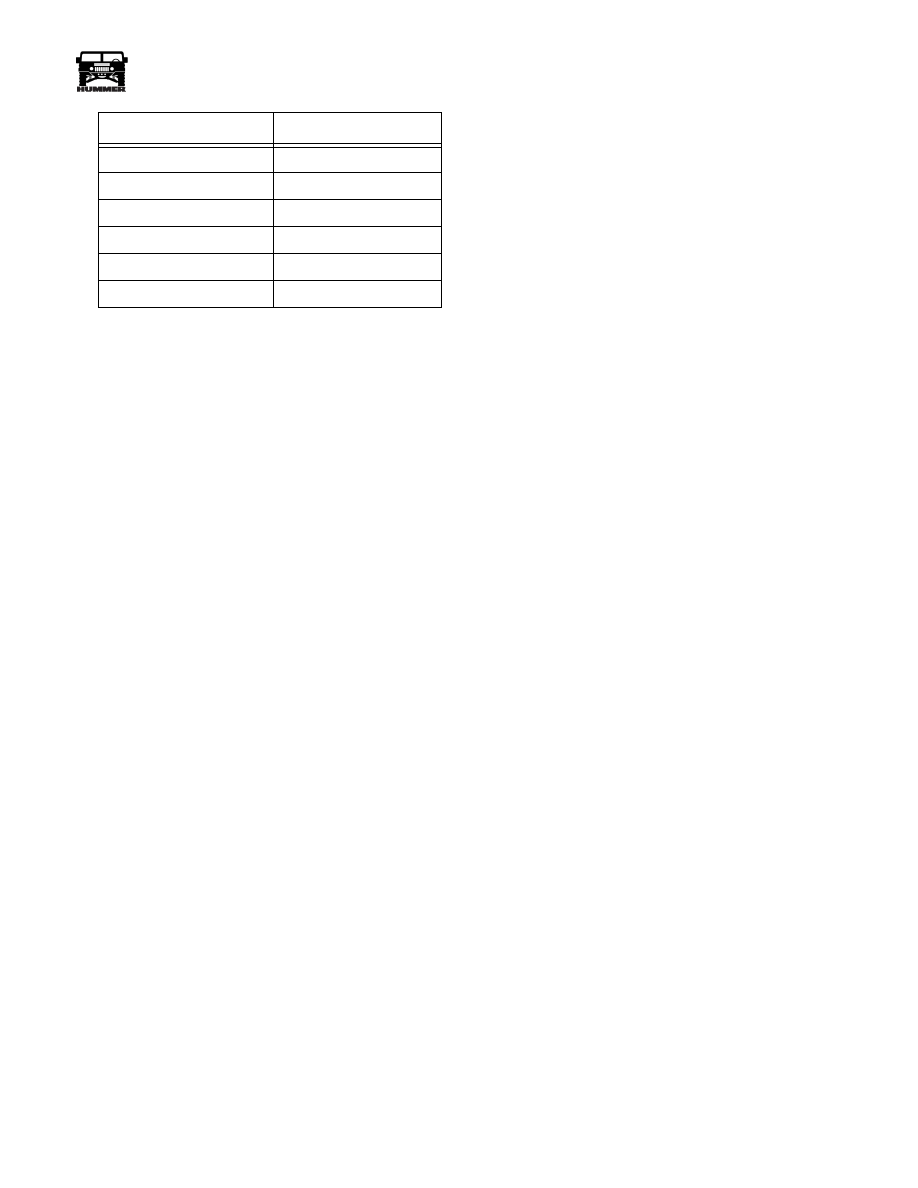

Figure 12-26: Load Test Values vs.Temperature

5.

If voltage drops below the minimum value listed, replace

the battery.

Parasitic Draw Test

Tools Required:

• J–38758 Parasitic Draw Test Switch

• J–39200 Digital Multimeter

1.

Remove the negative battery cable from the rear battery.

2.

Install the male end of the parasitic draw test switch over

the crossover negative battery cable using the long battery

bolt from the battery cable removed in step 1.

3.

Open the parasitic draw test switch

4.

Connect the negative battery cable to female end of the

parsitic draw test switch using a short battery bolt.

5.

Close the parsitic draw test switch.

6.

Road test the vehicle while activating all accessories, such

as the radio and air conditioning.

7.

Turn the ignition switch to the off position and remove the key.

NOTE: It is important that from this point on, electrical conti-

nuity must be maintained in the ground circuit to the battery,

either through J–38758 in the on position, or through J–39200.

8.

Some components, such as the PCM or TCM, have timers

that draw several amps of current while they cycle down.

This can give a false parasitic drain reading. Wait 15

minutes for these components to power down before

continuing this test.

NOTE: If another DVOM is being used other than J–39200,

ensure that the ammeter will handle 10 amps of current without

damage.

9.

Install a jumper wire with a 10 amp fuse between the two

terminals on the parasitic draw test switch. Open the

switch and wait 10 seconds. If the fuse does not blow, the

parasitic load is less than 10 amps and the J–39200 can be

used. Close the switch on the tester and remove the jumper

wire and fuse.

10. Set J–39200 to the 10 amp scale and place leads in the

correct ports in the meter for amperage testing on the 10

amp scale.

11. Connect the meter leads to the two terminals on the

parasitic load test switch and open the switch.

12. Wait 60 seconds then take a reading from the meter. If the

current reading is at or below 2 amps, turn the test switch

to the on position. Reset the meter to read milliamps.

13. Open the switch and take the reading in milliamps.

14. Find the reserve capacity of the batteries on the vehicle.

Since there are 2 batteries, add the reserve capacities

together. (100 minutes + 100 minutes = 200 minutes

reserve capacity). Divide the number by 4 and the answer,

given in milliamps, is the maximum allowable parasitic

drain the batteries will support.

NOTE: Always turn the switch knob to the “on” position be-

fore removing each fuse to maintain continuity in the electrical

system and to avoid damaging the meter due to accidental

overloading, such as opening a door to change a fuse.

15. If current draw is too high, remove system fuses one at a

time until the draw returns to a value less than or equal to

the maximum allowable for the batteries. Repeat the test

for parasitic drain after any repair has been performed.

16. When the cause of excessive current draw has been

located and repaired, remove the meter, test switch and

terminal adapters and connect the negative battery cable to

the battery.

Estimated Temperature

Minimum Voltage

70°F(21°C)

9.6

50°F(10°C)

9.4

30°F(0°C)

9.1

15°F(-10°C)

8.8

0°F(-18°C)

8.5

0°F(Below -18°C)

8.0

4-1-00