Hummer H1 (2002+). Manual - part 183

_____________________

Heating/Ventilation/Air Conditioning (HVAC) 11-11

®

05745159

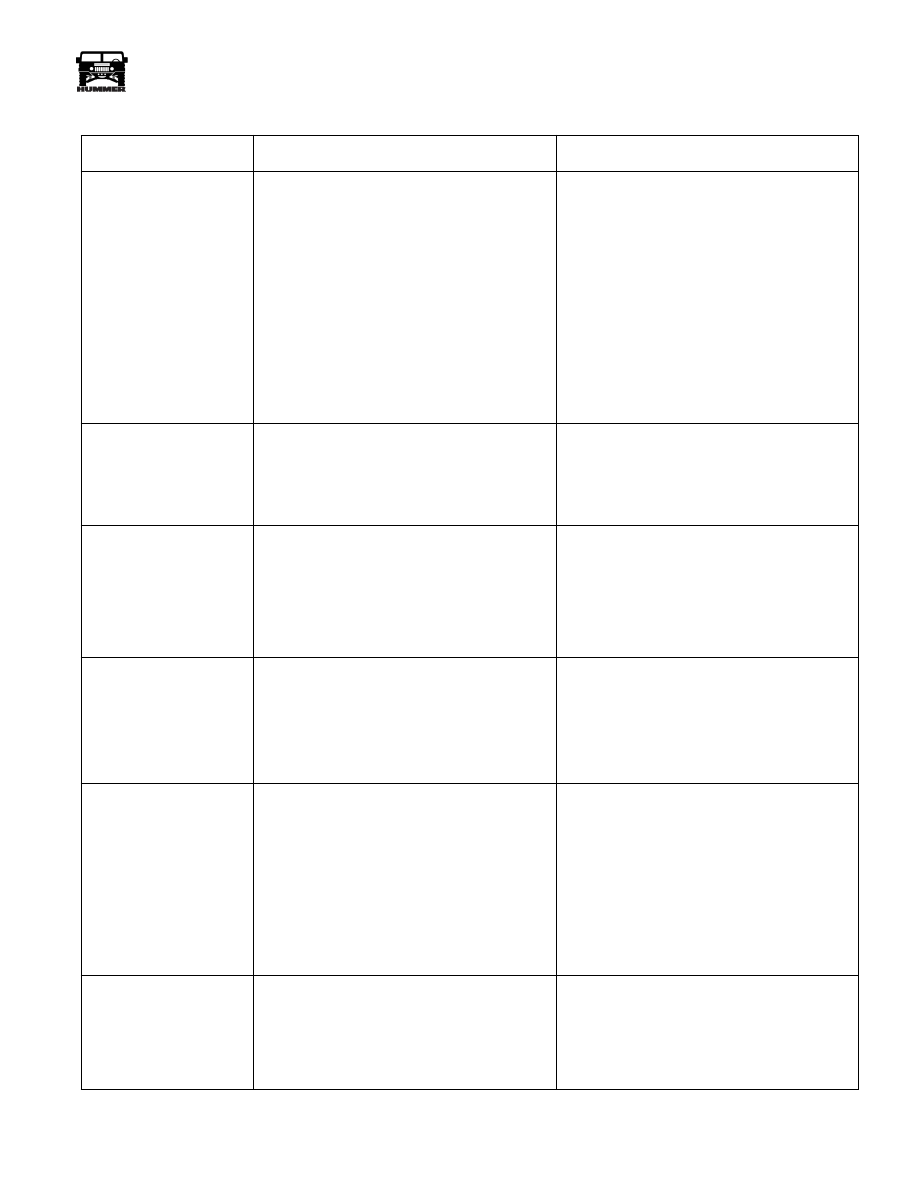

A/C Pressure Test Diagnosis

Condition

Possible Cause

Correction

Low Side High

High Side High

(Discharge Air Warm -

Discharge Line Warm to

Hot)

1.

Condenser fins obstructed or distorted.

1.

Clear obstruction with water spray and

compressed air. Straighten distorted fins

with tool J–36847 or equivalent.

2.

System overcharged.

2.

Recover excess charge with A/C service

cart J–39500-A.

3.

Air in system.

3.

Evacuate and recharge system.

4.

Expansion valve failed.

4.

Replace valve.

5.

Condenser restricted.

5.

Replace condenser. Evacuate and recharge

system.

6.

Compressor drive belt slipping.

6.

Replace belt or belt tensioner as needed.

Low Side High

High Side High

(Discharge Air Slightly

Cool - Discharge Line

Cool)

1.

Air and moisture in system.

1.

Discharge system. Replace receiver/dryer

and evacuate - recharge system.

2.

Leak at A/C line of 1/2 ounce or less.

2.

Locate with D-Tek leak tester. Recharge

system and verify proper operation.

Low Side Low

High Side Low

1.

System low on refrigerant.

1.

Add refrigerant and leak test system. Cor-

rect leak source and recharge as needed.

NOTE:

If leak was large, check compres-

sor oil level also and correct as needed.

2.

Expansion valve failed.

2. Replace valve, then evacuate and recharge

system.

Low Side High

High Side Low

1.

Internal leak in compressor

1.

Replace compressor and evacuate -

recharge system.

2.

Expansion

valve

failure.

2.

Discharge system. Replace valve and

recharge system.

3.

Drivebelt slip.

3.

Replace belt.

Low Side Low

High Side High

1.

Expansion valve failed.

1.

Discharge system. Replace valve and

recharge.

2.

A/C hose constricted, plugged.

2.

Check hose for kinks. Replace hose if

plugged and evacuate - recharge system.

3.

Receiver/Dryer restricted or has failed.

3.

Evacuate system. Replace receiver/dryer

and recharge system.

4.

Condenser problem (blocked, damaged).

4.

Evacuate system. Replace condenser and

recharge system.

Low Side and High Side

Normal But Cooling is

Inadequate

1.

Air and/or moisture in system.

1.

Leak test system. Repair leaks if neces-

sary. If leaks are not evident, evacuate and

recharge system.

2.

Receiver/Dryer fault.

2.

Evacuate system, replace receiver/dryer

and recharge system.