Hummer H1 (2002+). Manual - part 154

________________________________________

Axles, Suspension, and Frame 9-77

®

05745159

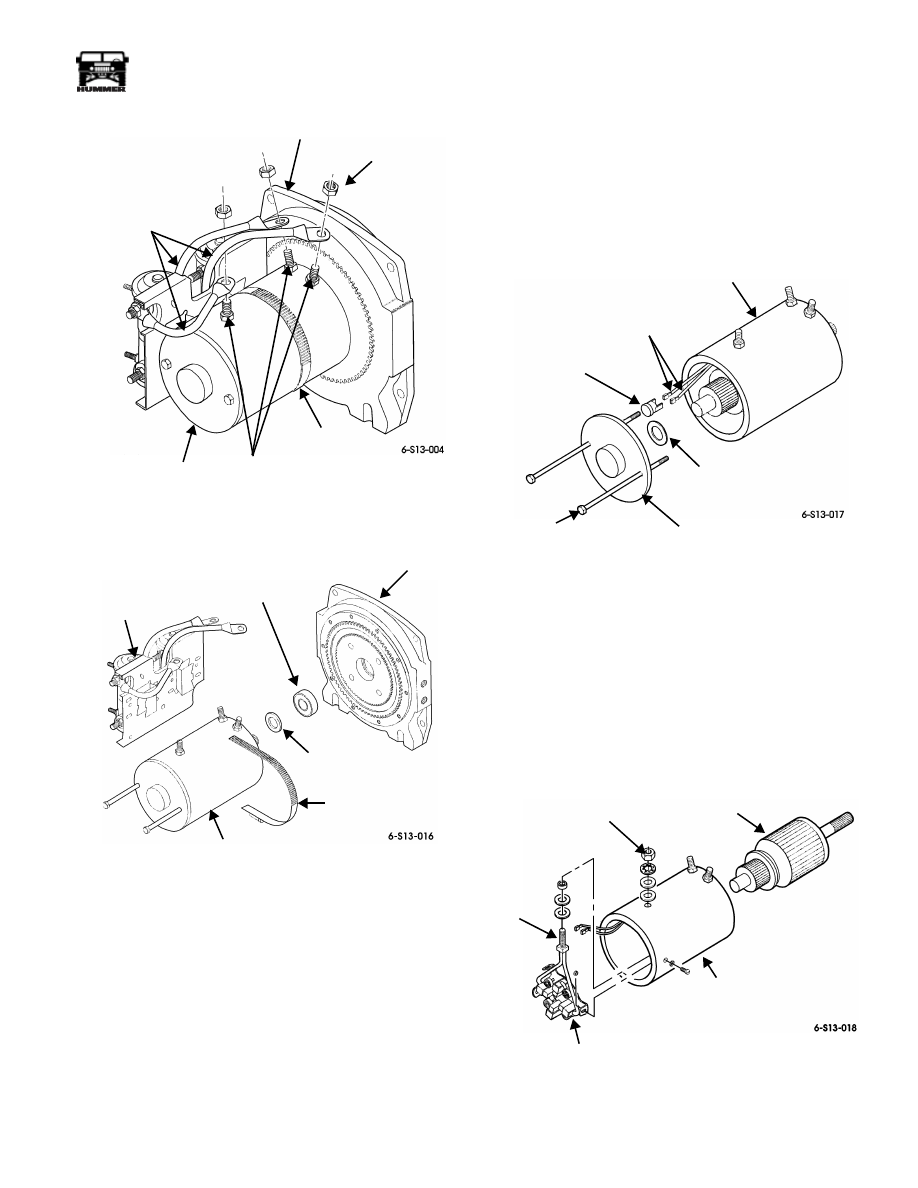

Figure 9-178: Control Leads

Figure 9-179: Control Unit and Motor

4.

Remove clamp from motor.

5.

Place winch on end with motor end up (Figure 9-180).

6.

Remove two bolt assemblies and rear cover from motor

housing.

NOTE:

Perform steps 7 through 11 only if replacing brush as-

sembly.

7.

Remove electric thermal switch from two electric thermal

switch leads.

8.

Remove motor housing from drum support and armature

assembly from brush assembly (Figure 9-181).

9.

Remove nut, lockwasher, washer, and insulator securing

brush assembly power stud to motor housing. Discard

lockwasher.

10. Remove three nuts, screws, and brush assembly from

motor housing.

11. Remove spacer, insulator, and washer from brush

assembly power stud.

Figure 9-180: Motor and Gasket

Installation

NOTE:

Do not apply coating to any electrical contacts of the

armature assembly. Perform steps 1 through 5 only if replacing

brush assembly.

1.

Install washer, insulator, and spacer on brush assembly

power stud (Figure 9-181).

2.

Install brush assembly in motor housing with three screws

and nuts

.

Figure 9-181: Brush Assembly and Armature

Assembly

CLAMP

DRUM SUPPORT

NUT

MOTOR

CONTROL

LEADS

TERMINALS

MOTOR

CLAMP

SPACER

BALL BEARING

DRUM SUPPORT

CONTROL

REAR COVER

SPACER

ELECTRIC THERMAL

SWITCH

ELECTRIC THERMAL

SWITCH LEADS

MOTOR

HOUSING

BOLT

ASSEMBLY

SPACER

MOTOR

HOUSING

ARMATURE

ASSEMBLY

BRUSH

BRUSH

POWER

ASSEMBLY

ASSEMBLY

STUD